Ejection blow molding method for making transparent plastic material water ball container and finished water ball container thereof

An injection molding and water polo technology, which is applied to the injection blow molding method of transparent plastic water polo containers and the finished products of water polo containers, can solve problems such as unevenness, achieve good appearance, increase acceptance and purchase desire, and increase quality Effects on sex and worth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

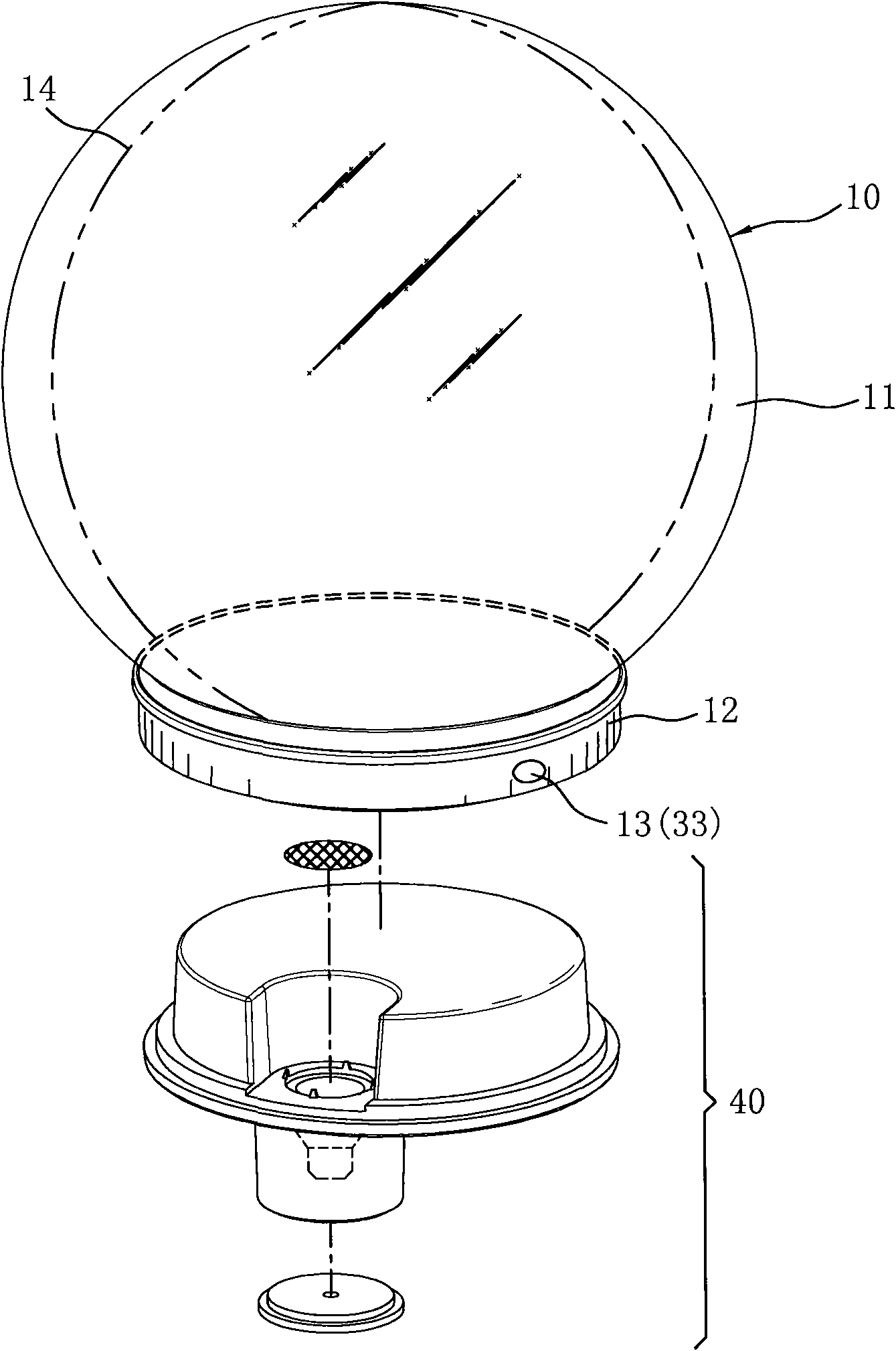

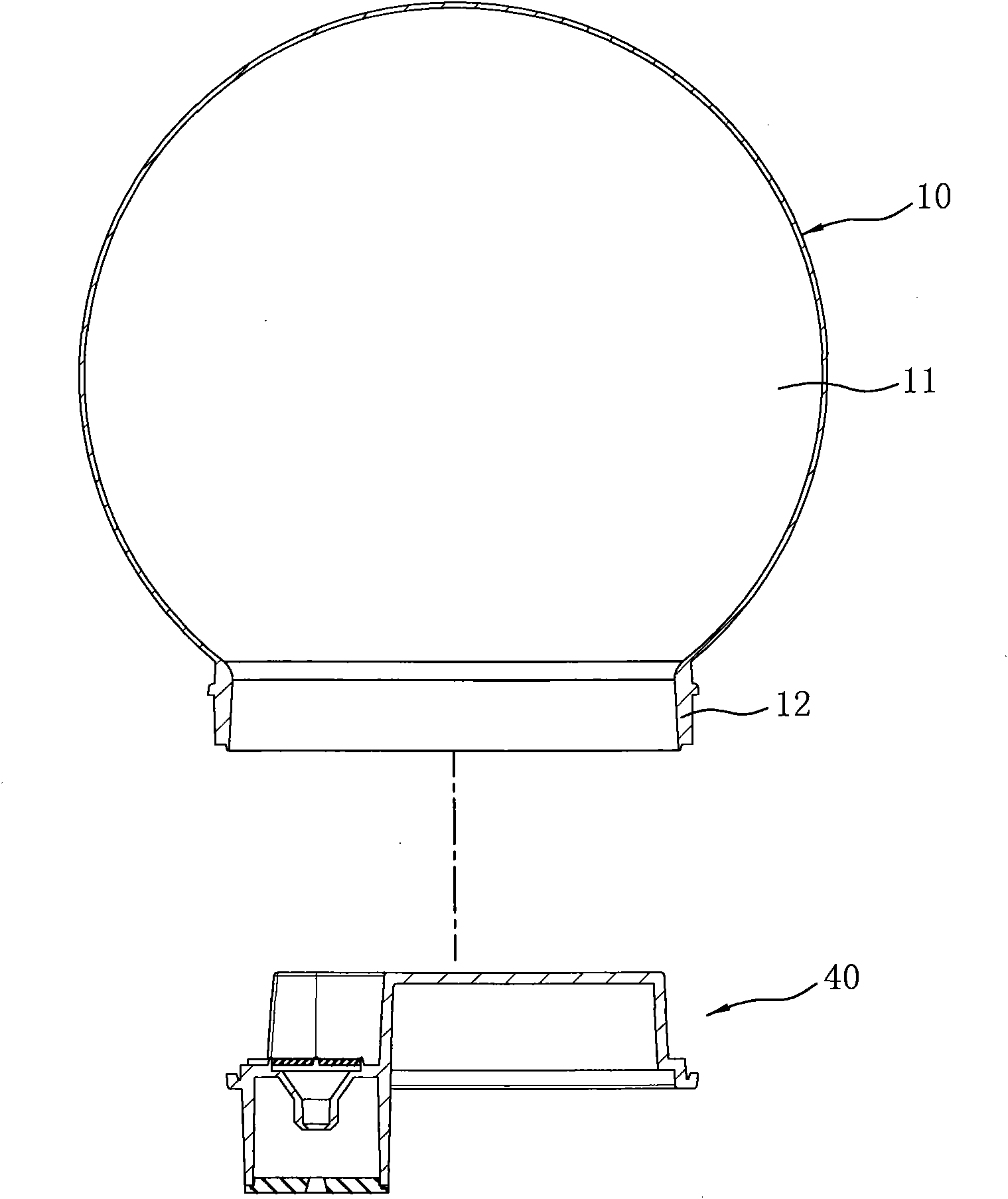

[0025]The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

[0026] refer to figure 1 , 2 , the present invention utilizes plastic material to make a transparent plastic material water polo container 10 such as figure 1 As shown, the transparent plastic material used therein includes PC (polycarbonate, Polycarbonate) or acrylic resin (Acrylic resin); The finished product of the water polo container 10 includes a spherical part 11 and a circular neck part 12, In addition, a bottom cover 40 is used to lock and close the neck portion 12 of the water polo container 10 to form an airtight container, wherein the locking method of the bottom cover 40 is not limited, and this embodiment is combined by ultrasonic welding.

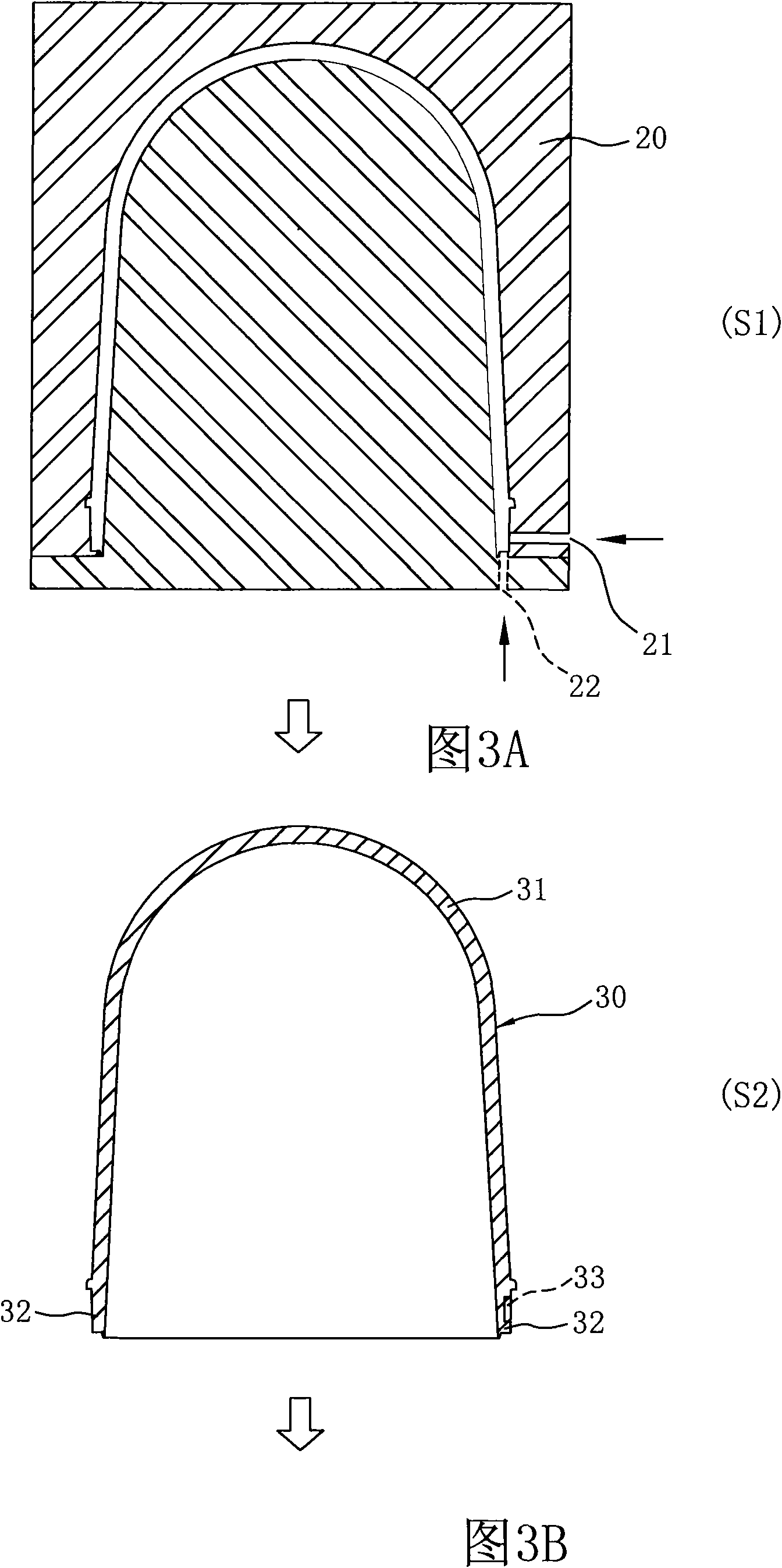

[0027] refer to Figure 3A-3F Shown, the injection blow molding (injection blow) manufacturing method of transparent plastic water polo container 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com