Light shielding sheet with predetermined light transmittance ratio and manufacturing method thereof

A technology of shading sheet and light transmittance, which is applied in the direction of textiles and papermaking, and can solve the problems of damaging the value of finished products, easy to produce fringe, and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The foregoing and other technical contents, features and functions of the present invention will be clearly understood in the following detailed description of preferred embodiments with reference to the accompanying drawings.

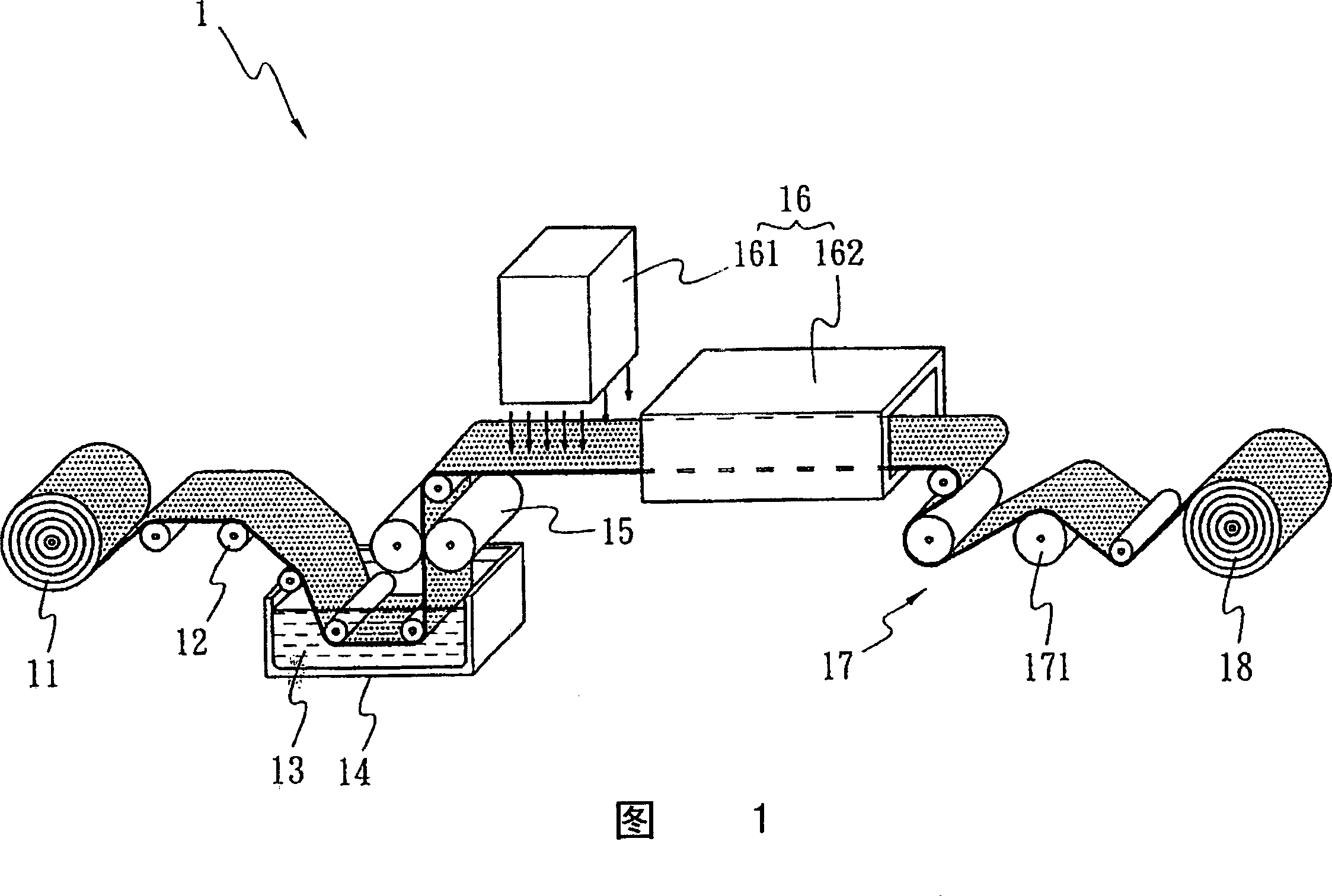

[0023] As shown in FIG. 1 , the present invention is used to manufacture the equipment 1 of the light-shielding sheet material with predetermined light transmittance, comprises the greige cloth 11 that rolls is guided by a plurality of rollers 12, passes through the impregnation tank 14 that paint 13 is housed in sequence, a Pressing roller 15, drying and shaping zone 16 (blowing device 161, dryer 162), and cooling zone 17 (cooling wheel 171), finally the shading sheet 18 is rolled into a cylinder for storage or transportation.

[0024] According to the operation sequence of the equipment shown in Figure 1, the manufacturing method of the light-shielding sheet 18 with predetermined light transmittance of the present invention comprises: providing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com