Handmade radix lithospermi soap and preparation method thereof

A technology of handmade soap and comfrey, applied in chemical instruments and methods, skin care preparations, alkali soap/ammonium soap composition, etc., can solve the problems of skin condition deterioration, loss of oil essence, etc., to improve eczema, Calming skin eczema, natural and beautiful color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

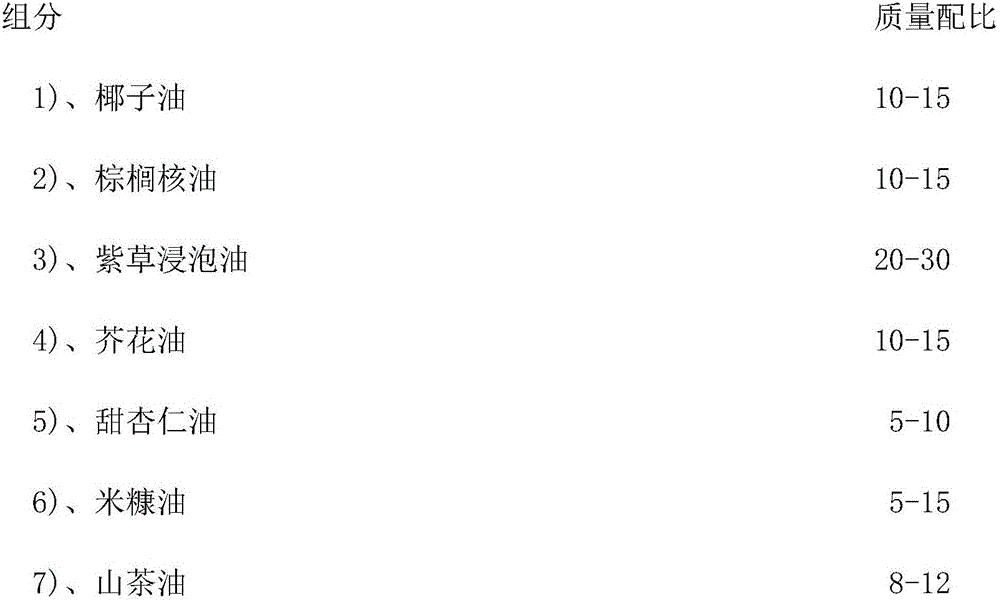

Image

Examples

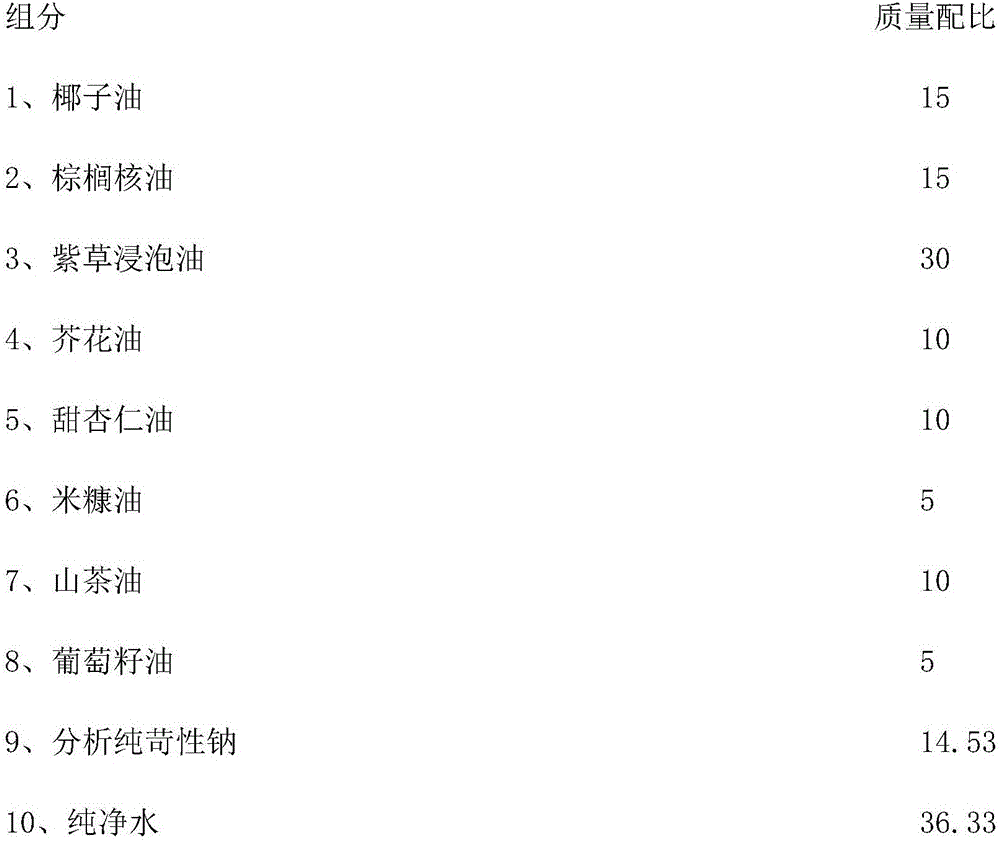

Embodiment 1

[0030]

[0031] The base oil used in the comfrey soaking oil is olive oil, the ratio of comfrey to base oil is 1:3, and the soaking time is 2 months.

[0032] The preparation method of comfrey handmade soap:

[0033] (1) Mix the above-mentioned coconut oil, palm kernel oil, comfrey soaking oil, canola oil, sweet almond oil, rice bran oil, camellia oil, and grape seed oil in proportion.

[0034] (2) While stirring, slowly pour caustic soda into purified water, continue stirring until the caustic soda is completely dissolved, and cool down to room temperature. Slowly pour the above-mentioned well-mixed oil into the lye, and keep stirring until the soap is viscous.

[0035] (3) The above-mentioned viscous soap liquid is poured into a mould, solidified, demoulded and naturally dried for one month, after which the product of the present invention is obtained.

Embodiment 2

[0037]

[0038] The base oil used in comfrey soaking oil is sunflower oil, the ratio of comfrey to base oil is 1:5, and the soaking time is 1 month.

[0039] The preparation method of comfrey handmade soap:

[0040] (1) Mix the above-mentioned coconut oil, palm kernel oil, comfrey soaking oil, canola oil, sweet almond oil, rice bran oil, camellia oil, and grape seed oil in proportion.

[0041] (2) While stirring, slowly pour caustic soda into purified water, continue stirring until the caustic soda is completely dissolved, and cool down to room temperature. Slowly pour the above-mentioned well-mixed oil into the lye, and keep stirring until the soap is viscous.

[0042] (3) The above-mentioned viscous soap liquid is poured into the mold, solidified, demoulded and naturally dried for one month, and then the product is obtained.

Embodiment 3

[0044]

[0045]

[0046] The base oil used in the comfrey soaking oil is grape seed oil, the ratio of comfrey to base oil is 1:7, and the soaking time is 3 months.

[0047] The preparation method of comfrey handmade soap:

[0048] (1) Mix the above-mentioned coconut oil, palm kernel oil, comfrey soaking oil, canola oil, sweet almond oil, rice bran oil, camellia oil, and grape seed oil in proportion.

[0049] (2) While stirring, slowly pour caustic soda into purified water, continue stirring until the caustic soda is completely dissolved, and cool down to room temperature. Slowly pour the above-mentioned well-mixed oil into the lye, and keep stirring until the soap is viscous.

[0050] (3) The above-mentioned viscous soap liquid is poured into the mold, solidified, demoulded and naturally dried for one month, and then the product is obtained.

[0051] A preferred embodiment of the present invention:

[0052]

[0053]

[0054] The base oil used in the comfrey soak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com