Weather-resistant halogen-free flame retardant PC/ASA alloy and preparation method thereof

A weather-resistant, alloy technology, applied in the field of modified engineering plastics, can solve the problem that the performance cannot meet the requirements of the use environment, and achieve the effects of outstanding performance, easy availability of raw materials, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific examples.

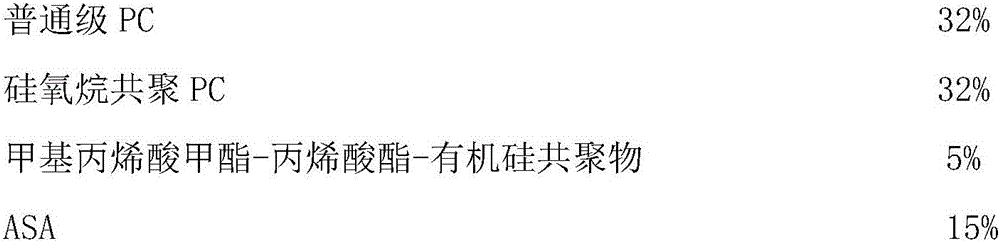

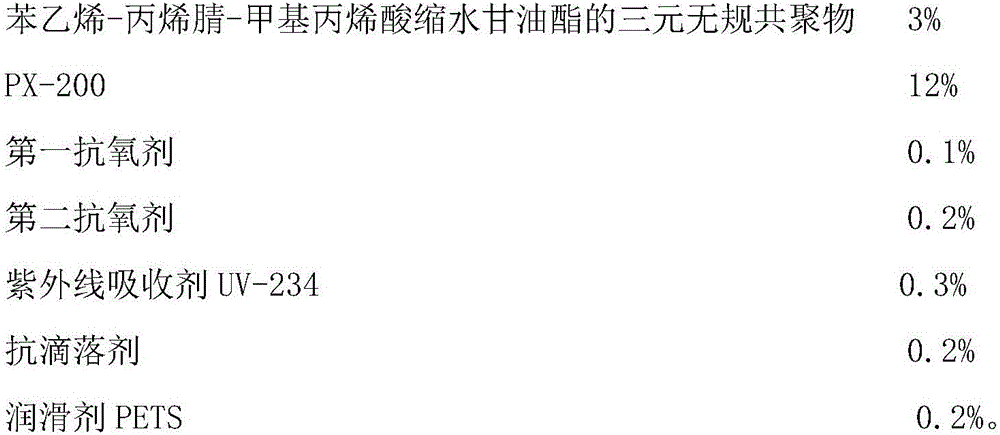

[0021] A weather-resistant halogen-free flame-retardant PC / ASA alloy, which is composed of the following raw materials in mass percentage:

[0022]

[0023]

[0024] Mix the above raw materials in a high mixer in a certain proportion; after mixing, extrude and cut into pellets through an extruder;

[0025] After drying, injection molded samples were tested for performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com