High-temperature energy-saving quicklime digestion reaction tank

A quicklime and reaction tank technology is applied in the field of high-temperature energy-saving quicklime digestion reaction tanks, which can solve problems such as incomplete digestion reaction, and achieve the effects of reducing digestion reaction time, reducing time used, and complete digestion reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

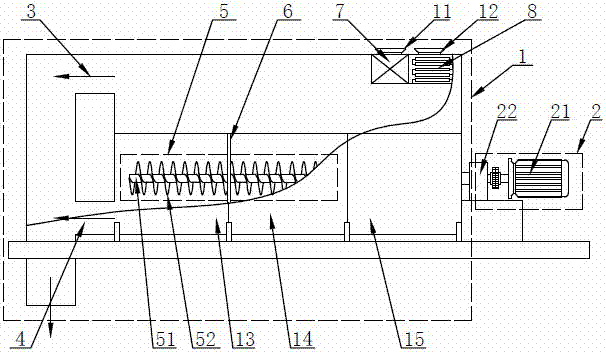

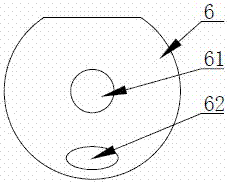

[0026] as attached figure 1 And attached figure 2 As shown, the high-temperature energy-saving quicklime digestion reaction tank includes a tank body 1 and a power mechanism 2, and a partition 6 is arranged inside the tank body 1, and the partition board 6 divides the tank body 1 into a first reaction tank 15, a second A reaction tank 14 and a third reaction tank 13, the top of the tank body 1 is provided with a water injection port 12 and a raw material injection port 11, the raw material injection port 11 is connected with a crushing device 7, and the water injection port 12 is connected with a heating device 8, The water injection port 12 and the raw material injection port 11 communicate with the first reaction tank 15 respectively, the power mechanism 2 includes a motor 21 and a speed reducer 22 connected with the motor 21, a stirring mechanism is arranged in the tank body 1, and the The stirring mechanism is a rotating stirring shaft 5, and the rotating stirring shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com