Method for synthesizing zeolite molecular sieve with chabasite structure

A technology of zeolite molecular sieve and chabazite, which is applied in the direction of crystalline aluminosilicate zeolite, etc., can solve problems such as difficult scale-up production, and achieve the effects of simple implementation conditions, convenient operation, and wide adjustable range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 4.0 grams of sodium hydroxide, 6.6 grams of potassium hydroxide (85%) and 75 grams of deionized water were prepared into a solution, 0.75 grams of 25% tetraethylammonium hydroxide solution was added, and 1.35 grams of aluminum powder was put in for dissolution. After the temperature of the solution dropped to room temperature, 12.0 g of white carbon black was added and stirred for half an hour until the hydrogel was evenly mixed. The molar ratio of the material for synthesizing the hydrogel is 0.05TEAOH (tetraethylammonium hydroxide): 2.0Na 2 O: 2.0K 2 O: Al 2 o 3 : 8SiO 2 : 150H 2 O. The mixture was left to stand at room temperature for half an hour, then transferred to a Teflon-lined stainless steel sealed kettle, heated to 85°C, and left to stand for three days. Then cool to room temperature, open the sealed kettle, pour off the supernatant, recover the white solid, and wash it three times with clear water. The resulting white powder was dried at 80°C.

[002...

Embodiment 2

[0031] Dissolve 4.0 g of sodium hydroxide and 19.7 g of 85% potassium hydroxide in 45.0 g of deionized water, add 2.5 g of ethylenediamine, and add 6.66 g of aluminum sulfate octadecahydrate to dissolve. Then, 60.0 g of 40% silica sol was slowly added while stirring, and the hydrogel was mixed evenly and stirred evenly, and then left to stand at room temperature for 12 hours. The molar ratio of the material for synthesizing the hydrogel is 8.0EDA (ethylenediamine): 10.0Na 2 O: 30.0K 2 O: Al 2 o 3: 80SiO 2 : 800H 2 O. The aged mixture was sealed in a Teflon-lined stainless steel autoclave, heated to 150 °C and allowed to stand for 5 days. Cool to room temperature, open the sealed kettle, pour off the supernatant, recover the white solid, and wash with water three times. The resulting white powder was dried at 80°C.

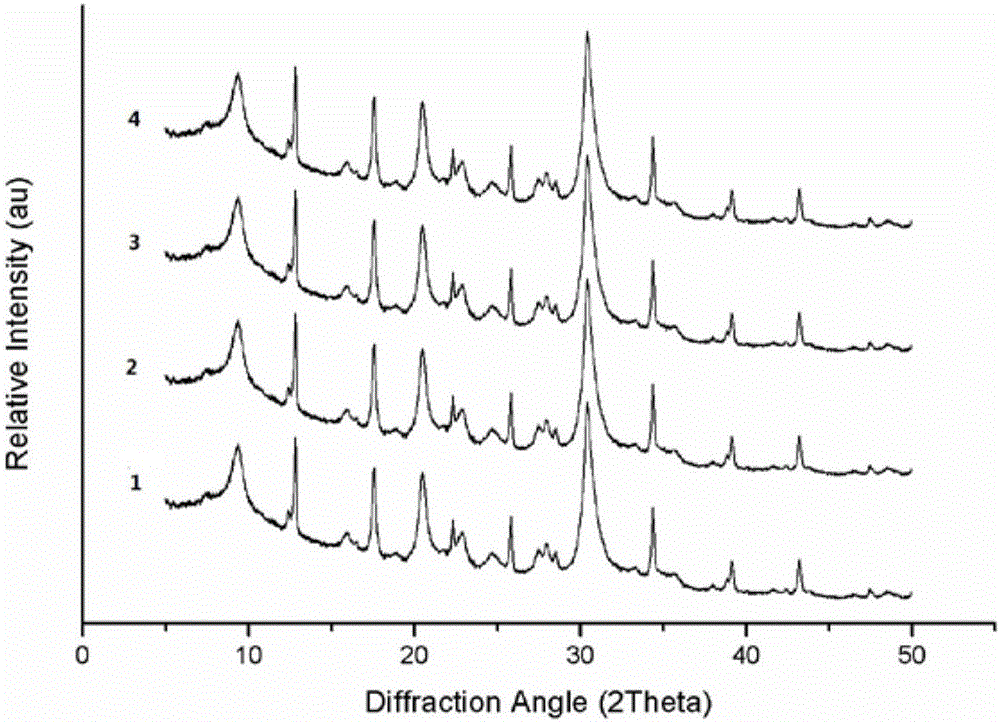

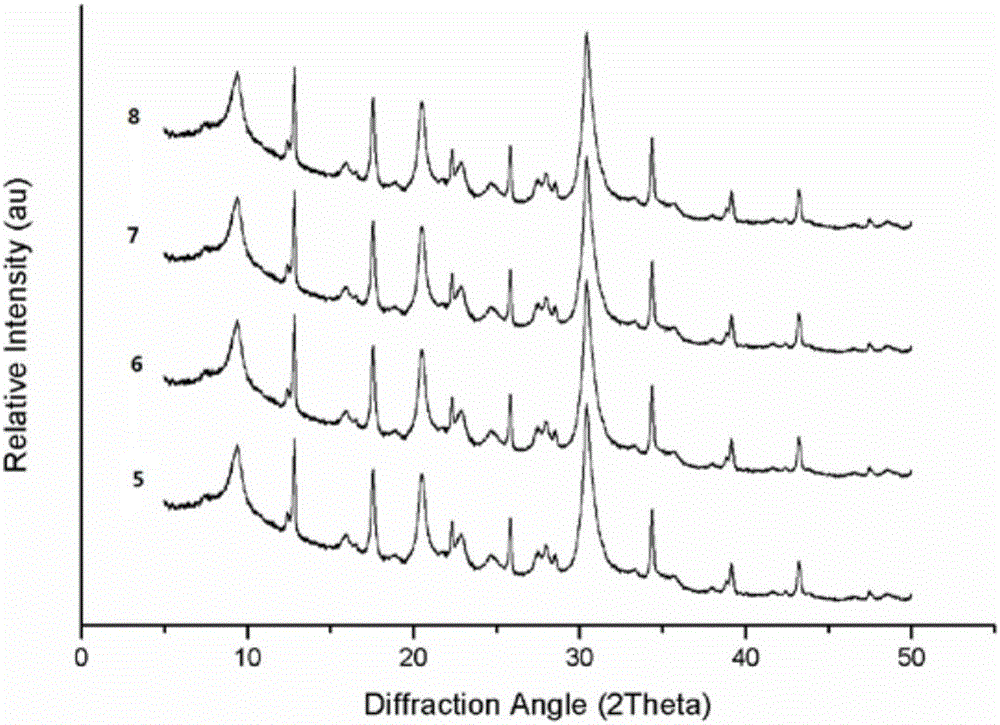

[0032] attached Figure 1-2 It is the powder X-ray diffraction pattern of the product obtained in this embodiment, and it can be known that the product is...

Embodiment 3

[0034] Dissolve 2.65 grams of potassium hydroxide in 12.0 grams of deionized water, add 1.0 grams of 25% tetrapropylammonium hydroxide solution, and add 0.82 grams of sodium metaaluminate to dissolve. Slowly add 7.5 grams of 40% silica sol under stirring, stir well to obtain a hydrogel, and the molar ratio of the material for synthesizing the hydrogel is 0.25TPAOH (tetrapropylammonium hydroxide): 1.0Na 2 O: 4.0K 2 O: Al 2 o 3 : 10SiO 2 : 190H 2 O. Without aging, directly transfer to a stainless steel kettle lined with Teflon, heat to 120 degrees Celsius, and turn the stainless steel kettle at a speed of 1 revolution per minute. Keep it for 12 hours, then cool to room temperature, open the sealed kettle, pour off the supernatant, recover the white solid, and wash it three times with water. The resulting white powder was dried at 80°C.

[0035] attached Figure 1-3 It is the powder X-ray diffraction pattern of the product obtained in this embodiment, and it can be known ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com