A detection system and method for complex operating conditions of a scraper conveyor

A technology for scraper conveyors and operating conditions, applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., to achieve the effect of maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below.

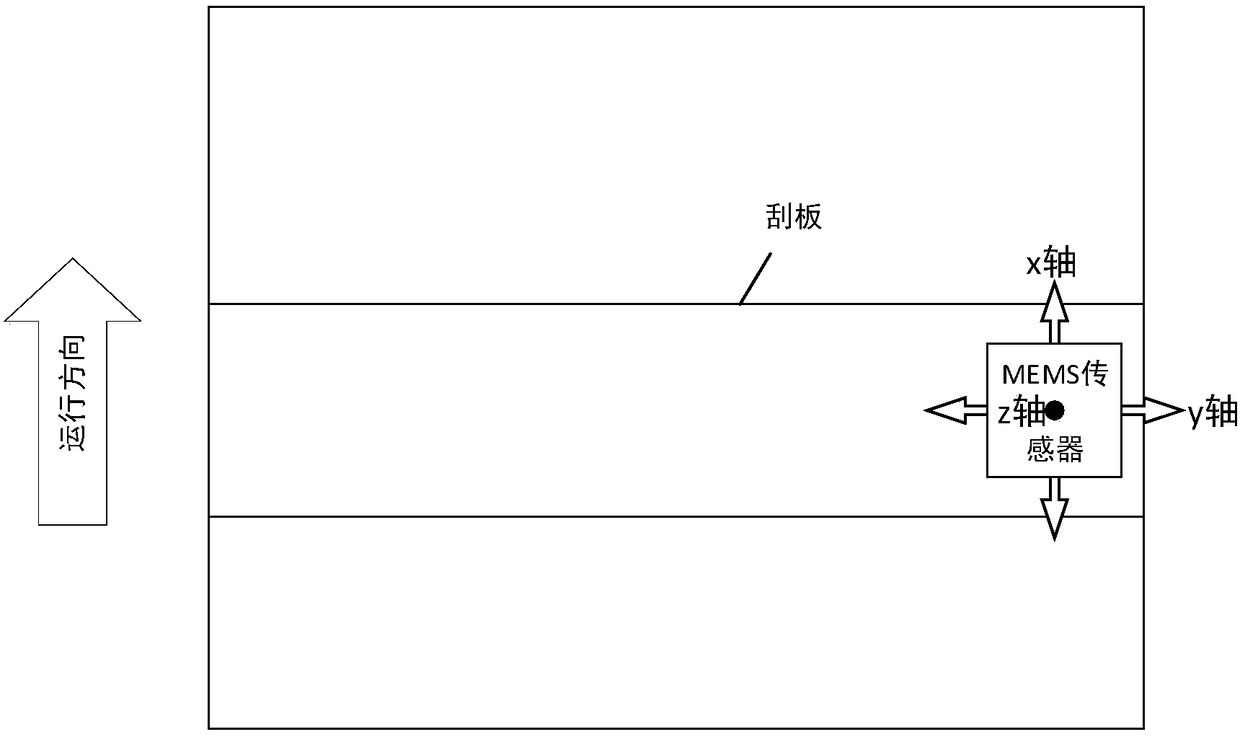

[0027] Such as figure 1 , 2 , 4 and 5, a detection system for complex operating conditions of scraper conveyors, including multiple inertial measurement devices, RFID transmitters, data receiving devices with WIFI functions, and data processing devices, and multiple inertial measurement devices are uniform Installed at intervals on the scraper of the scraper conveyor, the RFID transmitting device is installed at the tail of the scraper conveyor, and the data receiving device with WIFI function is arranged on the side of the scraper conveyor; the inertial measurement device consists of Six-axis MEMS sensor, memory card, WIFI module and RFID signal receiving device, the six-axis MEMS sensor is connected with the memory card, WIFI module and RFID signal receiving device respectively, and the described six-axis MEMS sensor is composed of a three-axis accelerometer and a three-axis gyroscope Composition, the three-ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com