Auxiliary brake damping system

A damping system and auxiliary braking technology, applied to vehicle parts, brakes, brake components, etc., can solve problems such as tire wear, high replacement frequency, and braking response that is not as expected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

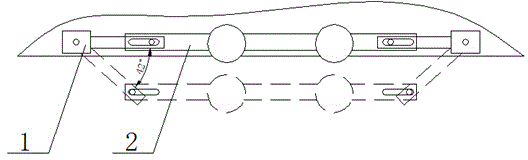

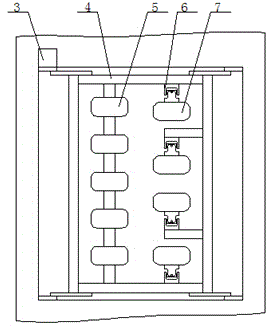

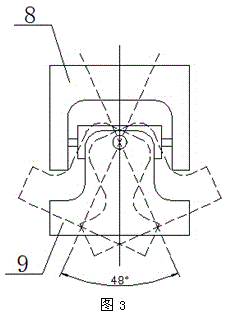

[0013] The embodiment of the present invention will be described in further detail below in conjunction with the accompanying drawings: the auxiliary brake damping system is characterized in that it includes a telescopic structure 1, and the telescopic structure 1 is installed on the bottom of the chassis, and a brake disc 2 is installed on the bottom of the telescopic structure 1. A directional damping wheel 5 is installed in front of the brake disc 2, a universal joint 6 and a universal damping wheel 7 are installed in the back, and the force sensitive sensor 3 is installed on the side of the telescopic structure 1. The quantity of described directional damping wheel 5 and universal damping wheel 7 can be selected according to the size and weight of the car.

[0014] The functions of each component are as follows.

[0015] 1. The telescopic structure 1 is a steel member, and its swing angle is 42°, which pushes the brake disc 2 to move down and touch the ground.

[0016] 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com