Three-dimensional ultrasonic elliptical vibration cutting device with parallel structure and trajectory generation method

An elliptical vibration, cutting device technology, applied in the driving device, fluid using vibration, large fixed members, etc., can solve the problems of low natural frequency, small working stroke, low working frequency, etc., to achieve excellent cutting performance, high efficiency, fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0048] In order to achieve the above object, the solution of the present invention is:

[0049] A three-dimensional elliptical vibration auxiliary cutting device with a parallel structure, characterized in that:

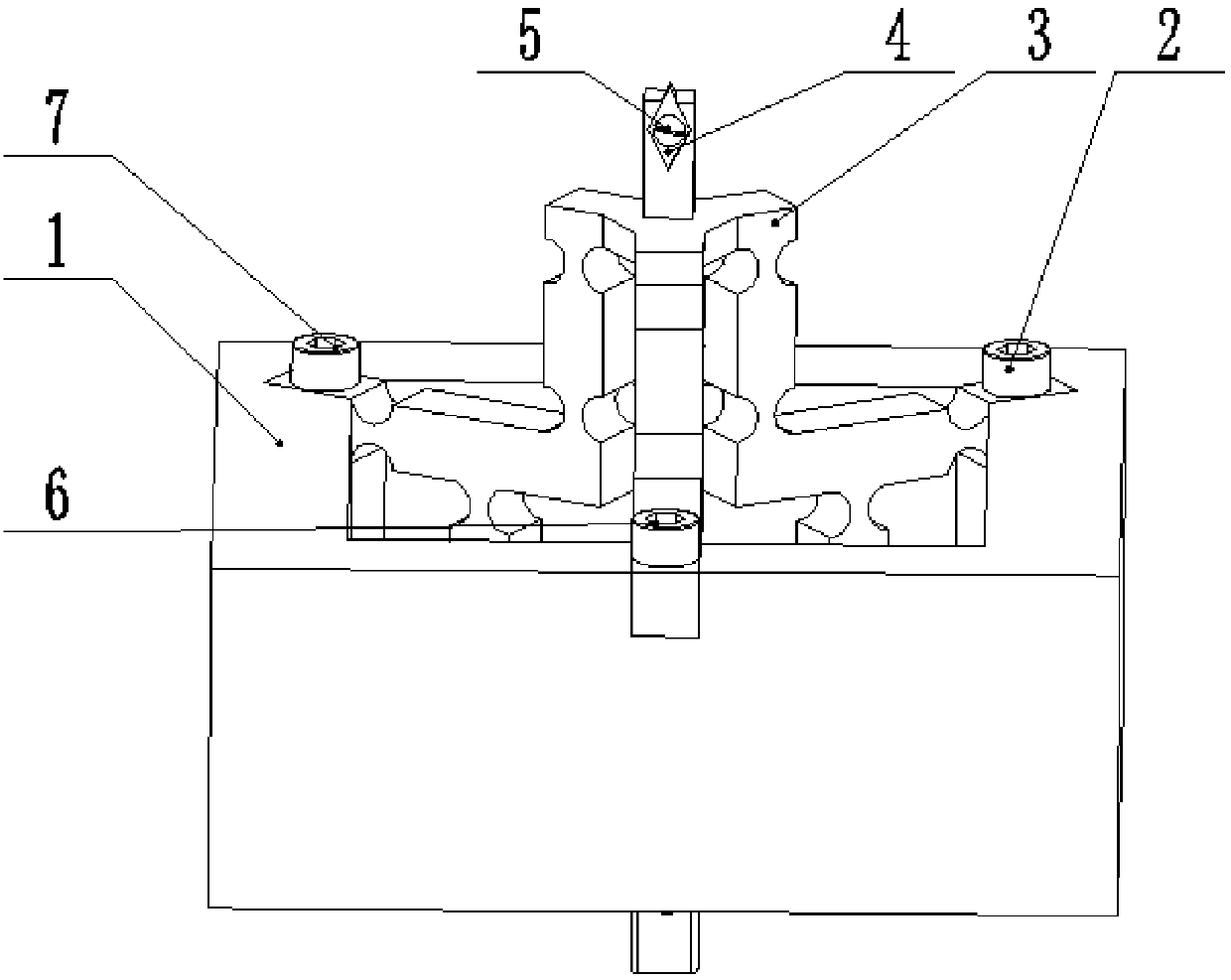

[0050] The device includes a base 1, a flexible hinge parallel structure 3, and a cutter 4, such as figure 1 shown;

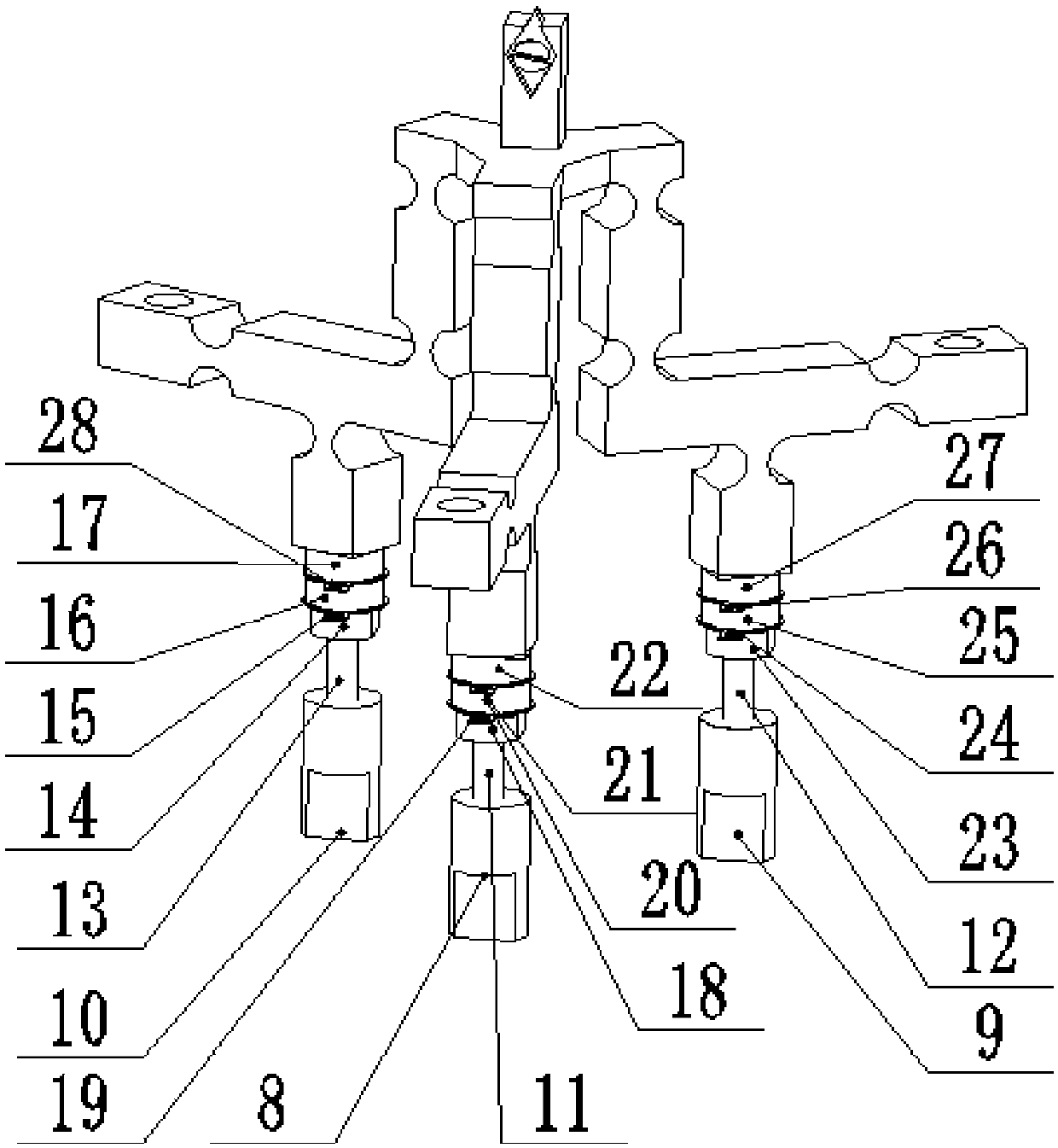

[0051] The above-mentioned flexible hinge parallel structure 3 includes a tool mounting platform 304, and also includes a first branch chain 301, a second branch chain 302, and a third branch chain 303, such as Figure 4 shown;

[0052] the above Figure 4 The three branch chain structures shown are identical, and all include a fixed rod 3011, an input rod 3012, an amplifying rod 3013, and a transmission rod 3014; the cross sections of the fixed rod 3011, the input rod 3012, the amplifying rod 3013, and the tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com