Electromagnetic valve body end face turning machining tool

A technology of face turning and processing machine tools, which is applied in the direction of metal processing machinery parts, turning equipment, turning equipment, etc. It can solve the problems of scrapped workpieces, low processing efficiency, and operators forgetting to remove them, so as to ensure that the clamping is in place and the cost of equipment is low. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

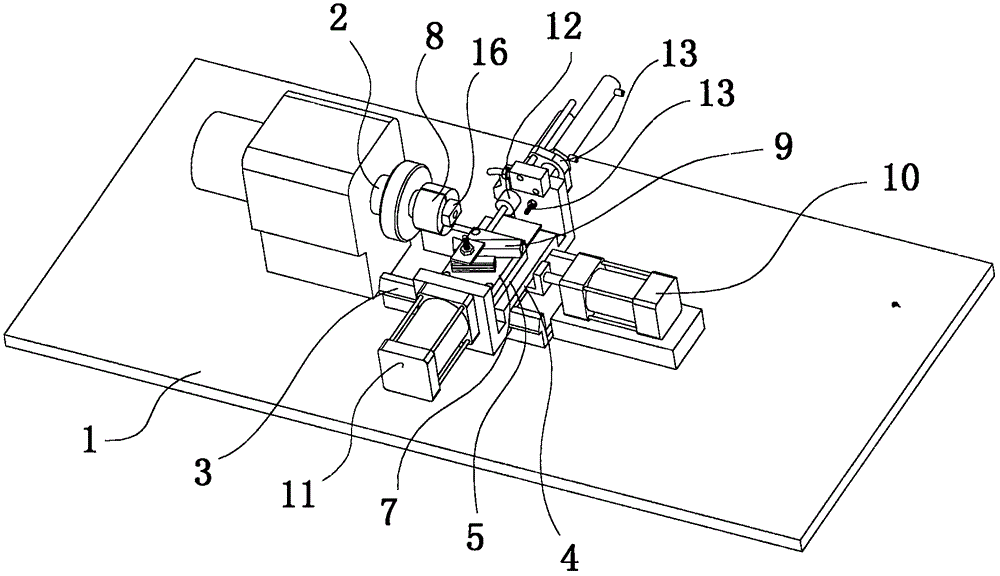

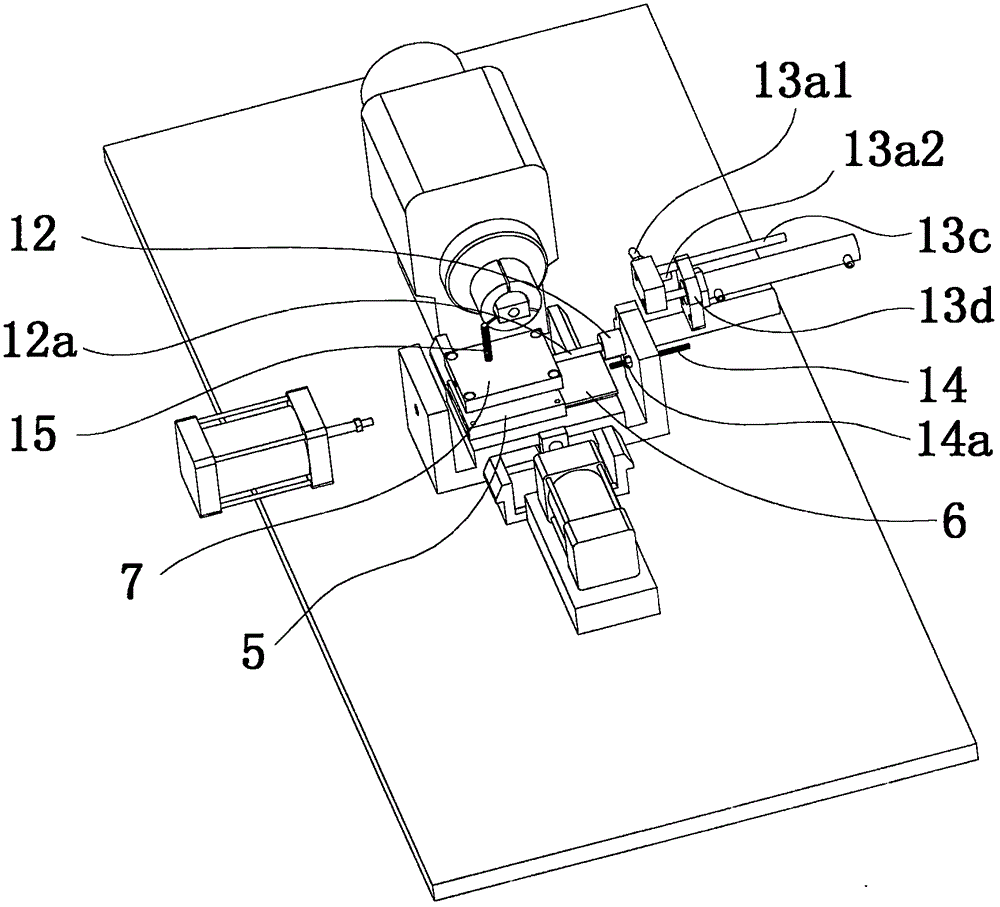

[0020] refer to Figure 1 to Figure 3 As shown, a kind of solenoid valve body end face turning machine tool of the present invention is technically transformed on the basis of an instrument lathe, including an organic platform 1, a main shaft 2 arranged on the machine platform 1, a longitudinal slide rail 3 and a machine tool arranged on the longitudinal slide rail The longitudinal sliding table 4 on 3 is the same as the traditional instrument lathe. The extending direction of the longitudinal sliding rail 3 is consistent with the axial direction of the main shaft 2. A special chuck 8 is installed on the main shaft 2, and the longitudinal sliding table 4 is installed on the longitudinal sliding rail 3. The upper part can slide back and forth relative to the main shaft 2 on the longitudinal slide rail 3, and the hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com