Feeding device for rolling mill

A rolling mill and frame technology, applied in the field of feeding devices, can solve the problems of increasing the replacement cost of support roller parts, low reliability of elastic swing mechanism, wear of mandrel and mandrel support roller, etc., and achieves good reliability and safety performance, avoid wear, and improve the smoothness of rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

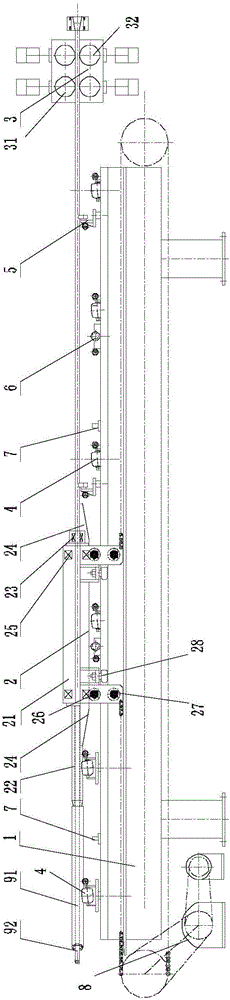

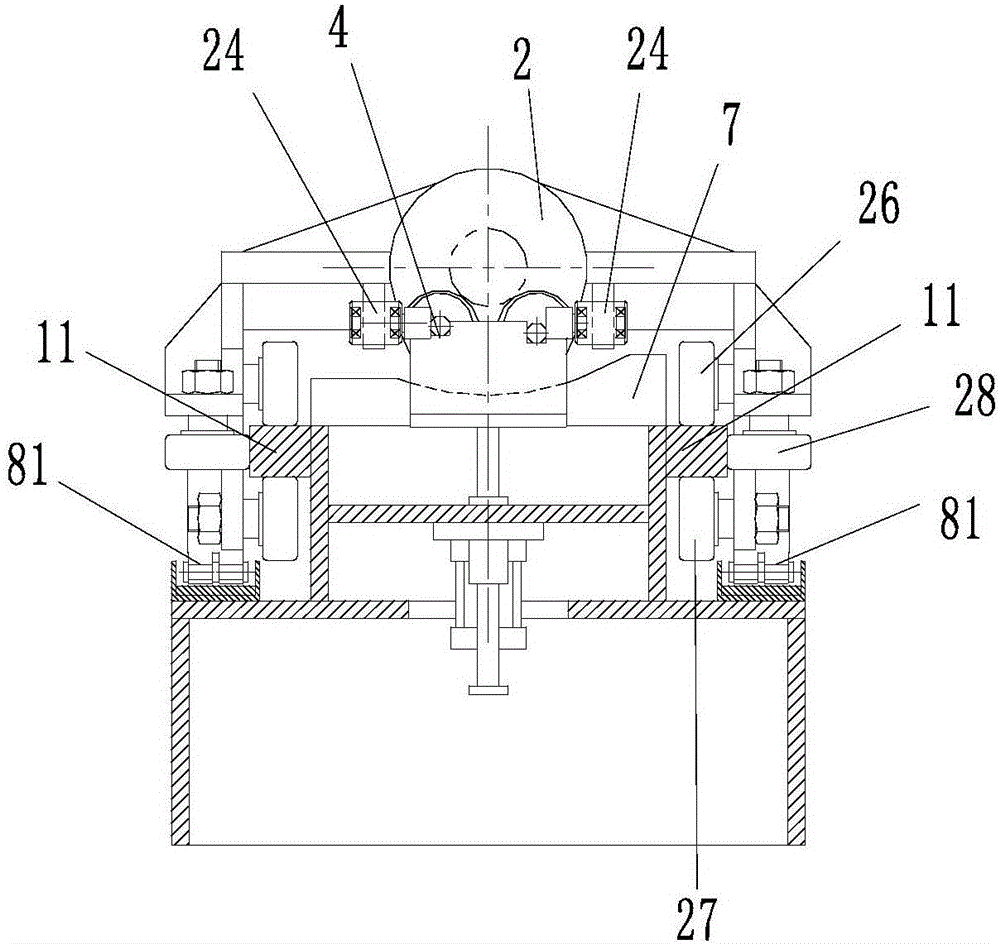

[0043] This embodiment is used for the feeding device of rolling mill, and its structure is as Figure 1 to Figure 10 As shown; including a frame 1, a mandrel, a mandrel feeding mechanism 3 for driving the mandrel to reciprocate along the rolling direction, a tube billet feeding trolley 2 movably arranged on the frame 1, and several cores Rod support mechanism and tube blank support mechanism 4. Each mandrel support mechanism and tube blank support mechanism 4 are respectively arranged on the frame 1 along the rolling direction. There are two kinds of mandrel support mechanisms, which are mandrel support mechanism one 5 and mandrel support mechanism two 6 respectively.

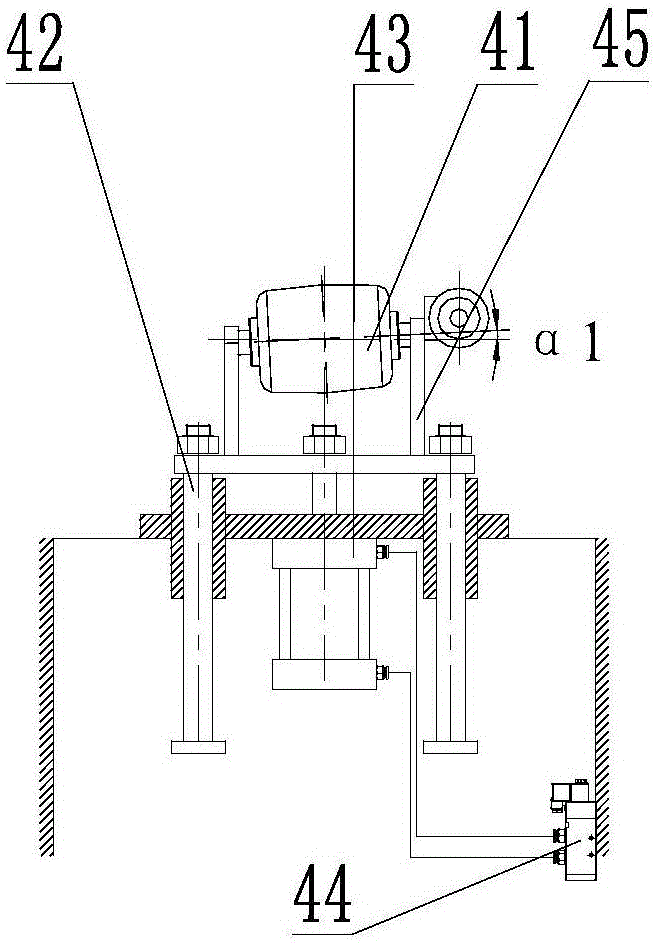

[0044] Each blank tube support mechanism 4 respectively includes a tube blank support part and a lifting module 1 43 . The tube blank supporting part includes a bracket 45 and two tube blank supporting rollers 41 rotatably arranged on the bracket 1 45; the two tube blank supporting rollers 41 jointly form a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com