Test apparatus for checking container products

A technology for inspecting equipment and containers, which is applied in the direction of instruments, scientific instruments, and types of packaging items. It can solve the problems of unsatisfactory inspection reliability and unsuitable inspection, and achieve high reliability and improve reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

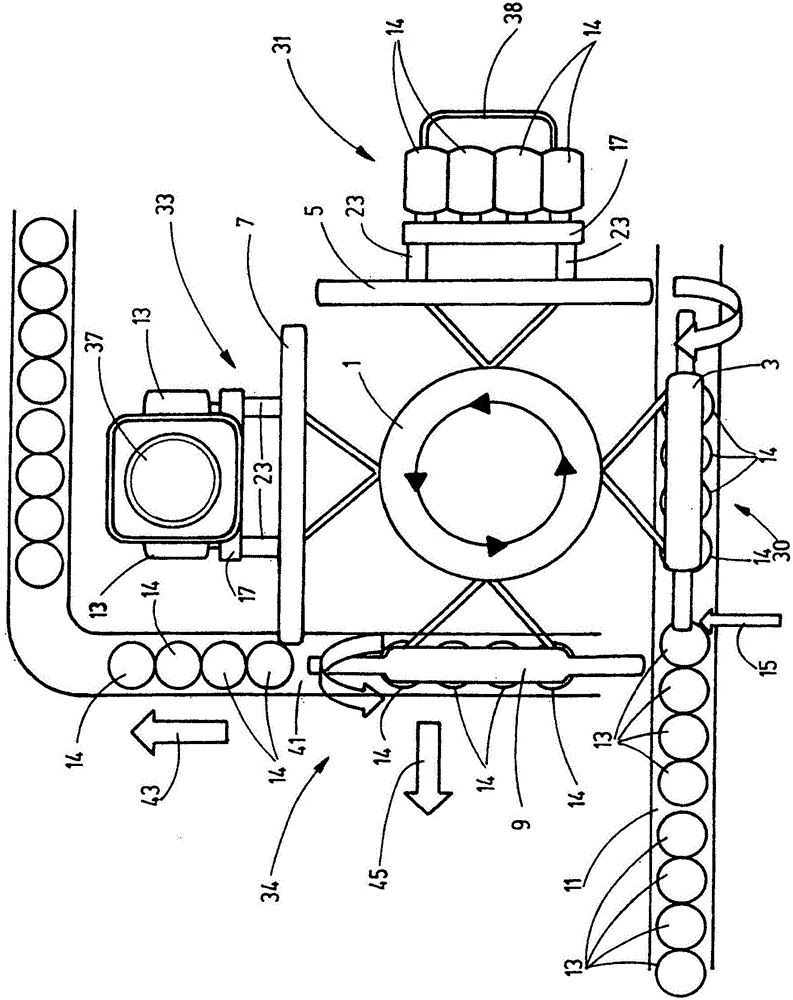

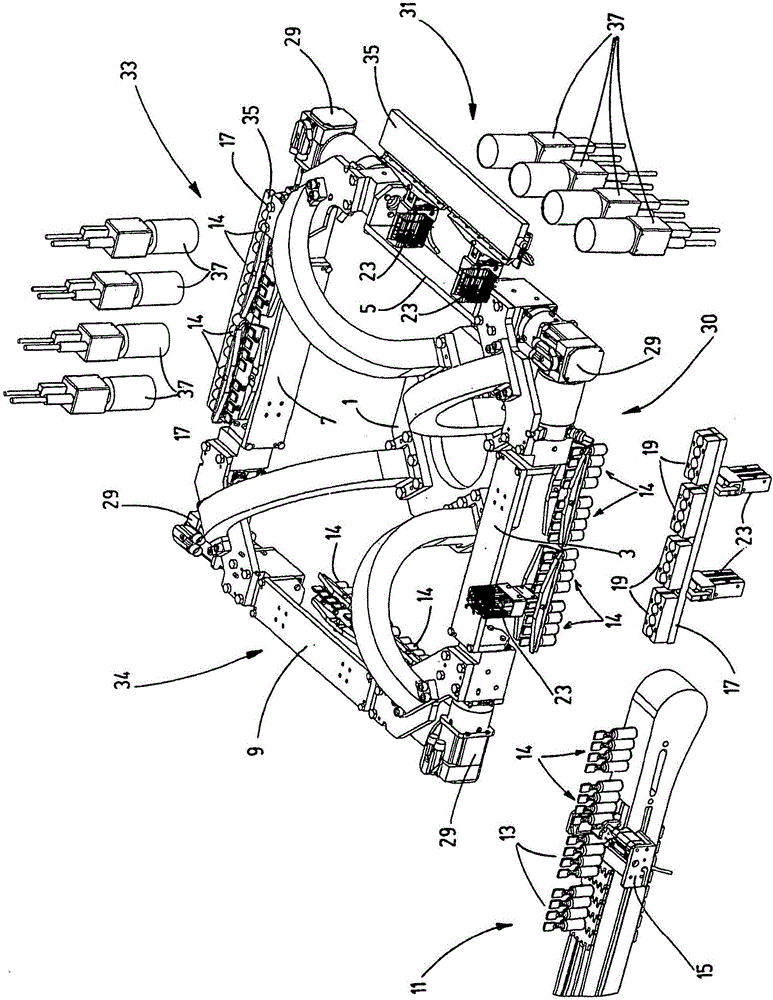

[0022] figure 1 A central actuating rotary drive, designated 1 , is shown, by means of which gripping devices 3 , 5 , 7 and 9 can be moved counterclockwise. By means of the belt conveyor 11 the ampoule 13 ( figure 2 ) is conveyed vertically as a container belt to a gripping device 3 located in a loading station 30 at the start of the inspection section formed by the actuating rotary drive 1 . Immediately before reaching the gripping device 3 , a separator 15 each separates the container cards, in the present case four ampoules 13 , from the container belt.

[0023] The gripping devices 3, 5, 7, 9 each have a carrying unit 17, figure 2 One of these carrier units is shown next to the belt conveyor 11 in a position removed from the carousel 1 . As can be seen from this illustration, each carrying unit 17 has four ampoules receptacles 19 in which a container card 14 with four ampoules 13 can be accommodated. Here, ampoules 13 are characterized by their figure 2 The closure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com