Cross-linking insulated tin-plated copper wire power cable resistant to high temperature and under 35kV

A tinned copper wire, cross-linked insulation technology, applied in the direction of power cables, insulated cables, power cables with shielding layer/conductive layer, etc., can solve the problems of insulation layer aging, affecting the use of cables, etc., to achieve high working temperature, The effect of large carrying capacity and small sag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

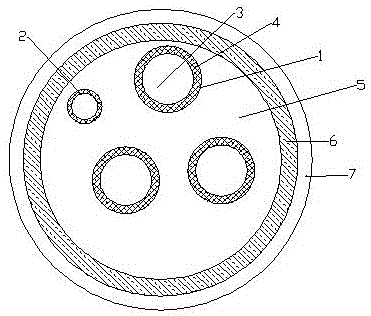

[0022] The structure of the power cable provided by the invention is as figure 1 As shown, there are 3 wire cores and 1 connecting wire core 2 inside the cable. The outside of the wire is covered with an insulating layer 4; the outside of the wire core 1 and the wire core 2 is surrounded by a shielding layer 6, and the space between the shielding layer 6 and the wire core 1 and the wire core 2 is a filling layer 5, A rubber sheath 7 is covered on the outside of the shielding layer 6 .

[0023] The tinned copper wire used in the present invention has extremely good solderability, and as time changes, the solderability remains good and can be stored for a long time. In addition, the surface of the tinned copper wire is smooth, bright and moist, and it has excellent performance Stable and reliable, ensuring the advantages of high quality and high yield.

[0024] The shielding layer on the cable structure in the present invention is a measure to improve the distribution of the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com