A microphone line array for on-site testing of sound scattering coefficient

A field test and microphone technology, applied in the field of microphone line array, can solve the problems of long test cycle, time-consuming and laborious processing and cutting, and high shape requirements, and achieve the effect of reducing measurement cost, simple measurement and low acoustic environment requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

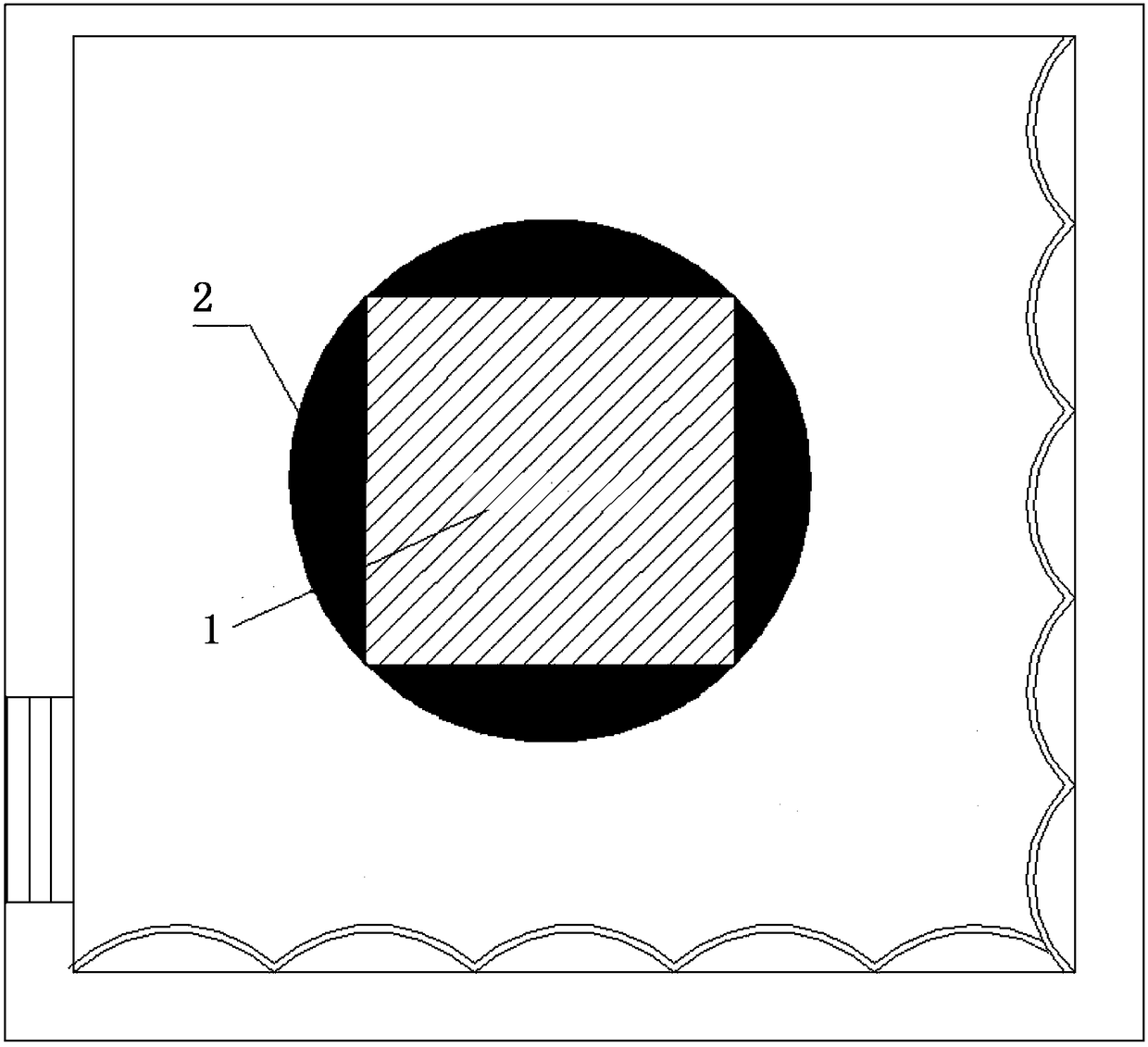

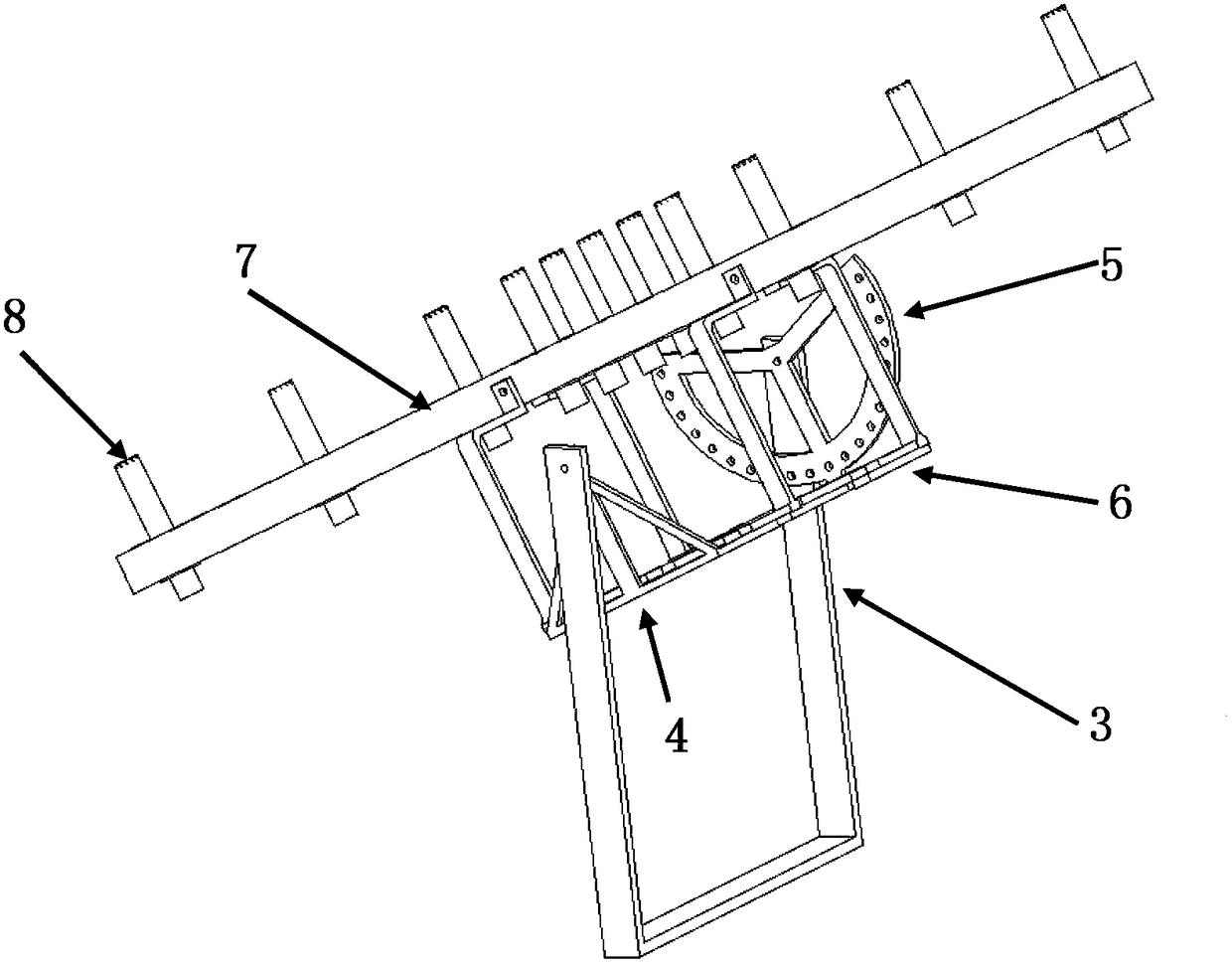

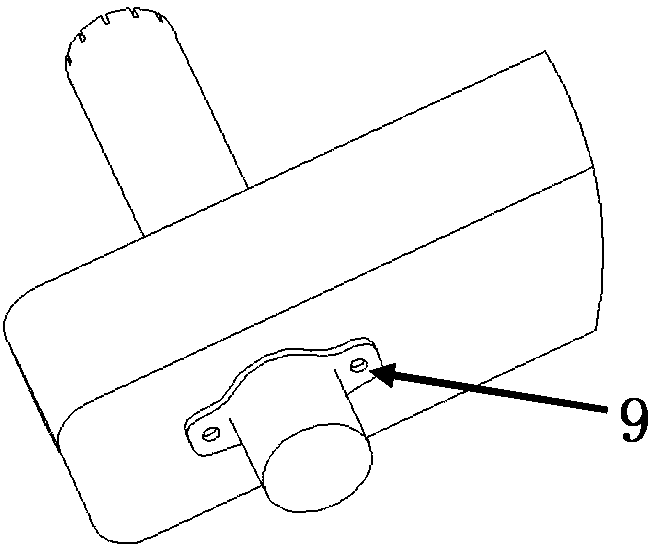

[0012] refer to figure 2 , image 3 , Figure 4 , a microphone line array for on-site testing of sound scattering coefficients, comprising a U-shaped fixed bracket 3, one end of the U-shaped fixed bracket is installed with a rotatable triangular bracket 4, the other end of the U-shaped fixed bracket is installed with an angle adjustment disc 5, the triangular bracket and The angle adjustment discs are equipped with connecting brackets 6, on which the microphone mounting plate 7 is fixed, the microphone mounting plate has holes, and the microphone 8 is installed and fixed on the microphone mounting plate through the rubber sleeve 9, and the rubber sleeve 9 passes through the microphone 8 surplus cooperation. The entire microphone line array is composed of 13 microphones arranged in a straight line with unequal distances, and the spacing between the microphones is 10 cm, 5 cm, 5 cm, 5 cm, 2.5 cm, 2.5 cm, 2.5 cm, 2.5 cm, 5 cm, 5 cm, 5 cm, 10 cm. The angle adjustment disc 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com