Organic waste gas catalytic purification device

A catalytic purification and organic waste gas technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems of life and property safety hazards, safety hazards of purification institutions, lack of safety guarantees, etc., to save energy, reduce safety problems, reduce The effect of safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

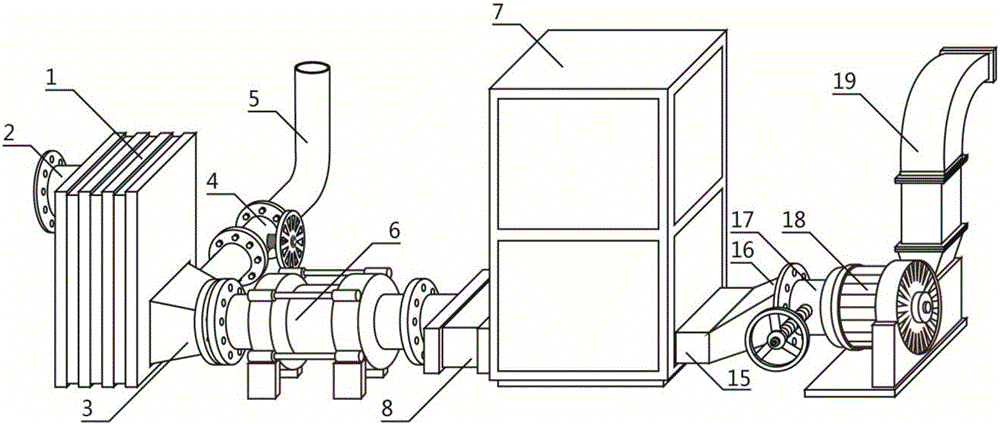

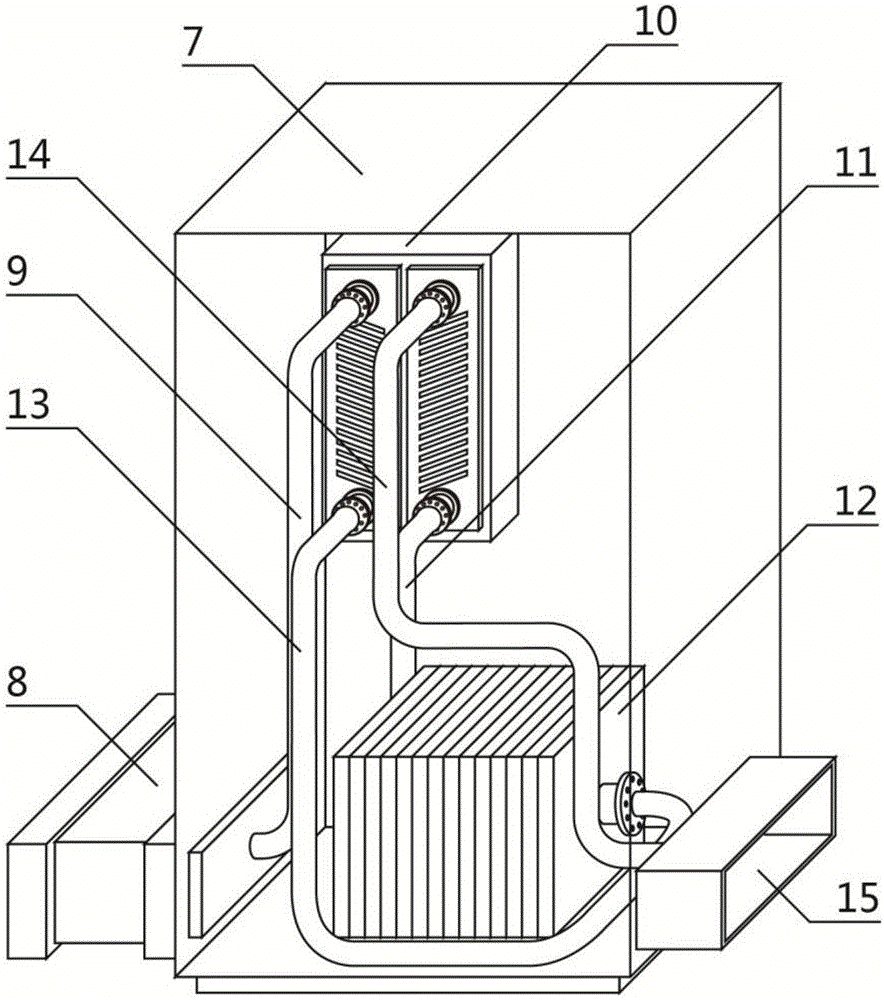

[0023] The specific implementation manners of the present invention will be briefly described below in conjunction with the accompanying drawings.

[0024] Such as figure 1 , figure 2A catalytic purification device for organic waste gas is shown, which is characterized in that it consists of a pre-processing device 1, a pre-processing output pipe 3, an emergency vent valve 4, a flame arrester 6, a catalytic purification device 7, a purified gas delivery pipe 16, and an air volume adjustment Valve 17, blower fan 18 and clean gas discharge pipeline 19 are formed, and described pretreatment device 1 is also provided with pretreatment inlet 2, and described pretreatment inlet 2 is positioned at the side of pretreatment device 1, so The pretreatment air inlet 2 is fixedly connected to the pretreatment device 1, the pretreatment output pipeline 3 is located on the other side of the pretreatment device 1, and the pretreatment output pipeline 3 is fixed to the pretreatment device 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com