A kind of PC alloy material and its preparation method and application

An alloy material, a technology of cyclohexane dimethanol ester, which is applied in the field of PC alloy material and its preparation, can solve the problem of insufficient fluidity, warpage performance, internal stress performance, mold release performance, and color and luster can not achieve good results and other problems to achieve the effect of color improvement and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0087] In embodiment and comparative example, the preparation method of described PC alloy material, comprises the steps:

[0088] 1) Weigh each component according to the formula content, and mix the polycarbonate, polyethylene terephthalate-1,4-cyclohexanedimethylene ester, fibrous filler, and other additives that need to be pre-dried Carry out pre-drying treatment at 120℃~130℃;

[0089] 2) Mix the pre-dried polycarbonate, polyethylene terephthalate-1,4-cyclohexanedimethanol, fibrous fillers, and other additives evenly through a high-speed mixer;

[0090] 3) Pass the homogeneously mixed polycarbonate, polyethylene terephthalate-1,4-cyclohexanedimethanol, other additives, zirconium salt or zirconium oxide through the main feeding port, fibrous The filler is fed into the twin-screw extruder through the main feeding port or the side feeding port, and the temperature control setting temperature of the twin-screw extruder is 200 ° C ~ 280 ° C;

[0091] 4) Cooling and dicing. T...

Embodiment 0~29 and comparative example 1~4

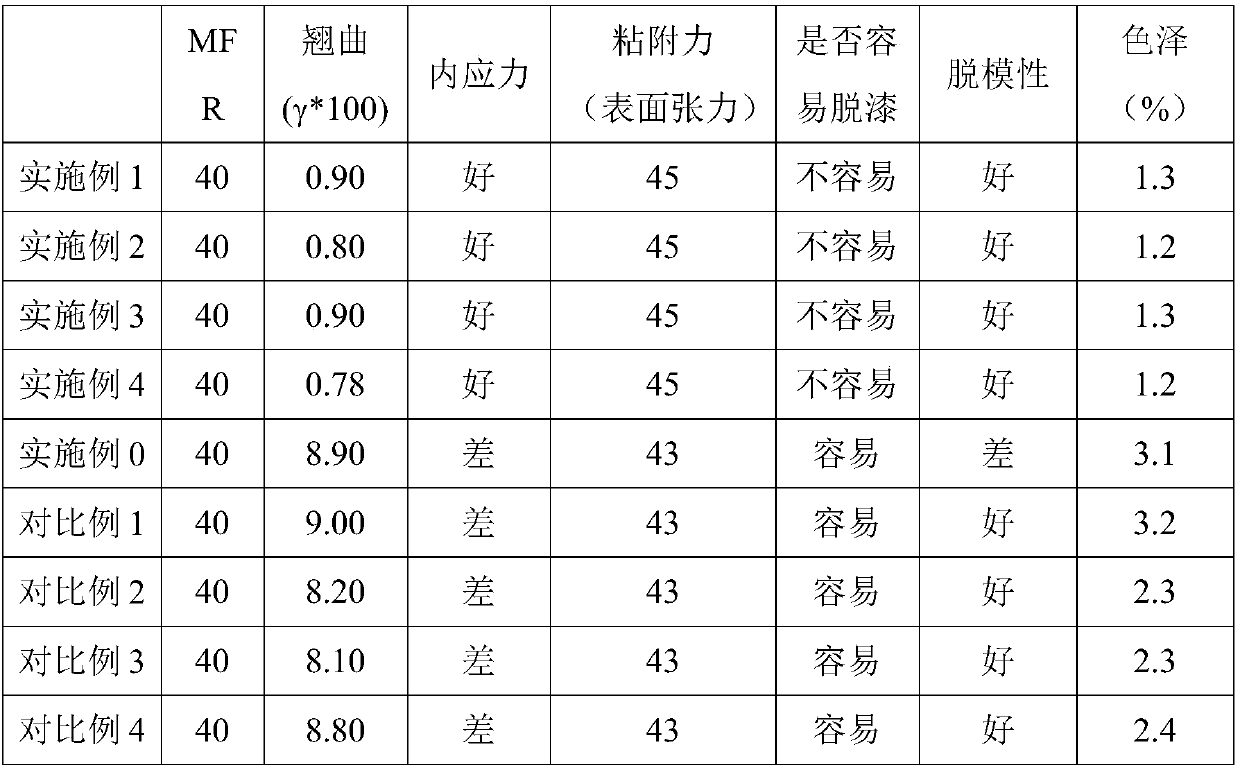

[0098] According to the formulations in Table 1 and Table 2, the PC alloy materials of Examples 0-4 and Comparative Examples 1-4 were prepared, and their performance tests are shown in Table 3. It can be seen from Examples 1 to 4 that when zirconium is added to the PC alloy material, the warpage, internal stress, mold release, and color properties of the PC alloy material are significantly improved. From the comparison of Examples 1-4 and Comparative Examples 1-4, it can be seen that when the content of zirconium element added to the PC alloy material is too high, the warpage, internal stress, and color properties of the PC alloy material will be significantly affected .

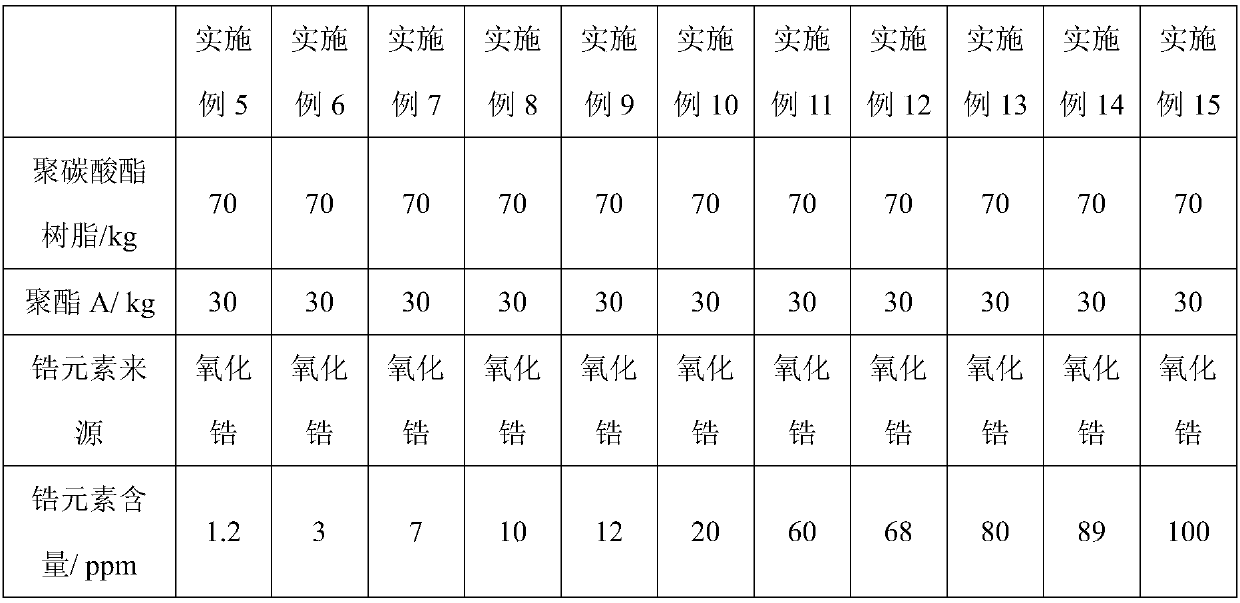

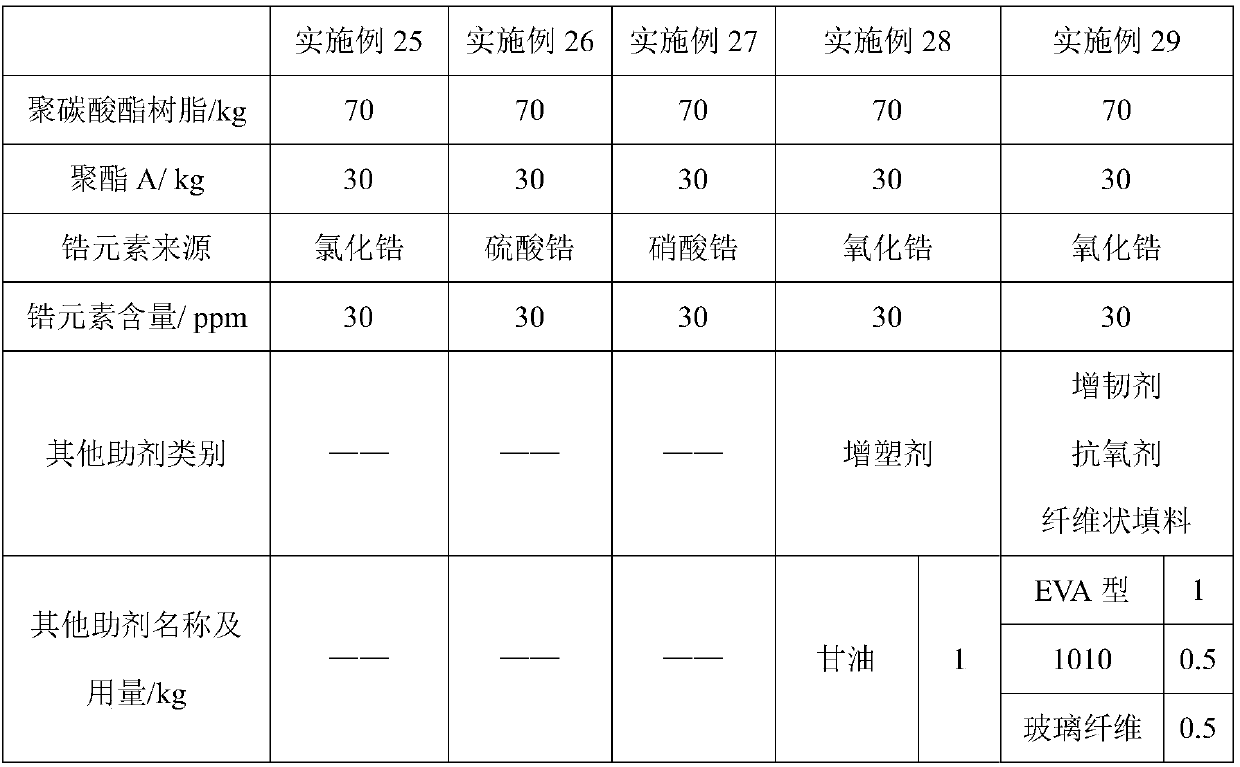

[0099] According to the formulations in Tables 4, 5, 6, and 7, the PC alloy materials of Examples 5-29 were prepared, and their performance tests are shown in Table 8. It can be seen from Examples 1 to 29 that the schemes of adding an appropriate amount of metal elements in the present invention can improve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com