Preparation method of high-performance magnetorheological nano composite polymer gel

A polymer gel and nanocomposite technology, which is applied in the field of high-performance magnetorheological nanocomposite polymer gel preparation, can solve the problem that mechanical properties and magnetorheological properties cannot be improved at the same time, and the dispersibility of magnetorheological polymer gels cannot be improved at the same time. , poor stability and other problems, to achieve the effects of good controllability of the three-dimensional network structure, increased interaction force, improved stability and dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

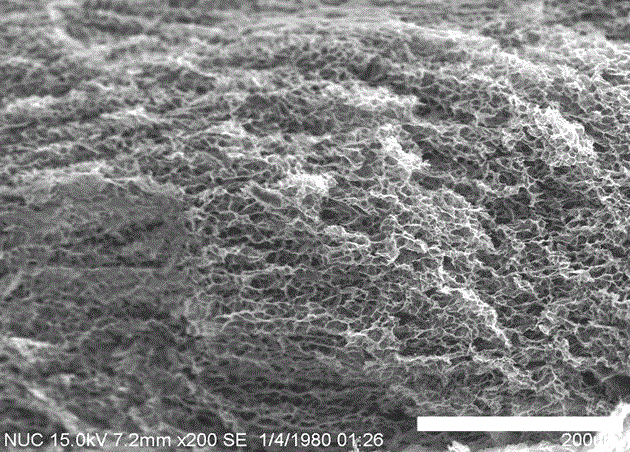

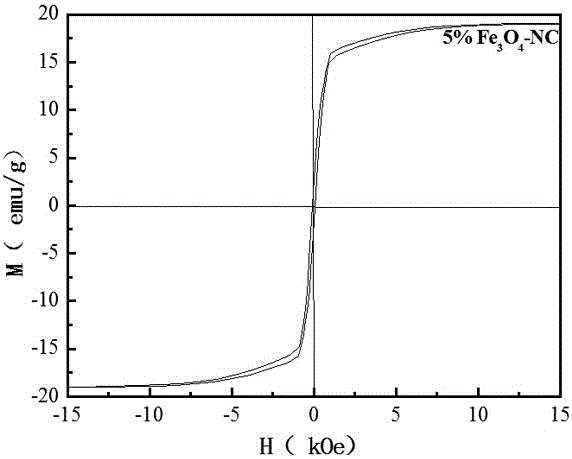

Image

Examples

Embodiment 1

[0020] Embodiment 1: A method for preparing a magnetorheological nanocomposite polymer gel, comprising the following steps:

[0021] 1) Co-precipitation method to prepare Fe 3 o 4 Nano magnetic particle stable dispersion:

[0022] 3.58g of FeCl 2 • 4H 2 O, 6.08g of FeCl 3 •6H 2 O and Fe 2+ Salt and Fe 3+ Dissolve 0.5wt% surfactant dopamine hydrochloride in 90ml of deionized water based on the total mass of the salt; after stirring and dissolving evenly at a speed of 500r / min at 50.0°C, slowly add Fe 2+ Salt and Fe 3+NaOH solution with a volume ratio of 1:1 and a concentration of 1.5 mol / L in saline solution, and then continue to react for 90 minutes to form a stable black dispersion liquid; the stable black dispersion liquid is separated by magnetic separation method to separate magnetic particles, ultrasonically dispersed, and then Magnetic separation, repeated 3 times, redispersed into a certain amount of deionized water to form Fe 3 o 4 Nanomagnetic particles wit...

Embodiment 2

[0027] Embodiment 2: A method for preparing a magnetorheological nanocomposite polymer gel, comprising the following steps:

[0028] 1) Co-precipitation method to prepare Fe 3 o 4 Nano magnetic particle stable dispersion:

[0029] 3.58g of FeCl 2 • 4H 2 O, 7.3g of FeCl 3 •6H 2 O and Fe 2+ Salt and Fe 3+ 2wt% surfactant ethylenediaminetetraacetic acid of the total mass of the salt was dissolved in 90ml of deionized water; after stirring and dissolving evenly with mechanical stirring at a speed of 500r / min and at 50.0°C, slowly drop it at a rate of 1 drop / second Add Fe 2+ Salt and Fe 3+ NaOH solution with a volume ratio of 1:1 and a concentration of 1.5 mol / L in saline solution, and then continue to react for 90 minutes to form a stable black dispersion liquid; the stable black dispersion liquid is separated by magnetic separation method to separate magnetic particles, ultrasonically dispersed, and then Magnetic separation, repeated 3 times, redispersed into a certain ...

Embodiment 3

[0034] Embodiment 3: A method for preparing a magnetorheological nanocomposite polymer gel, comprising the following steps:

[0035] 1) Co-precipitation method to prepare Fe 3 o 4 Nano magnetic particle stable dispersion:

[0036] 3.58g of FeCl 2 • 4H 2 O, 7.3g of FeCl 3 •6H 2 O and Fe 2+ Salt and Fe 3+ The surfactant polyvinyl alcohol of 2wt% of salt total mass is dissolved in a certain amount of deionized water, and the consumption of described deionized water guarantees Fe 2+ Salt and Fe 3+ The total concentration of the brine solution is 5.0wt%; after the mechanical stirring at a speed of 500r / min and the temperature of 50.0°C stirs and dissolves evenly, slowly add Fe at a rate of 1 drop / second 2+ Salt and Fe 3+ NaOH solution with a volume ratio of 1:1 and a concentration of 1.5 mol / L in saline solution, and then continue to react for 90 minutes to form a stable black dispersion; use magnetic separation to separate the magnetic particles from the stable black dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com