Formwork grabbing and lifting aligning machine and using method thereof

A technology of alignment machine and formwork, applied in cranes, load hanging components, transportation and packaging, etc., can solve the problem of limited freedom of self-propelled aerial work vehicles, inapplicability of lifting equipment or tunnel trolley, and inability to complete formwork alignment Adjustment and other issues to achieve the effect of strong adaptability, improved operation quality and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

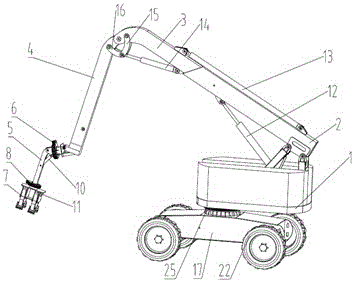

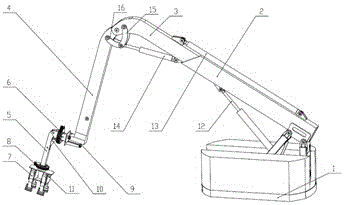

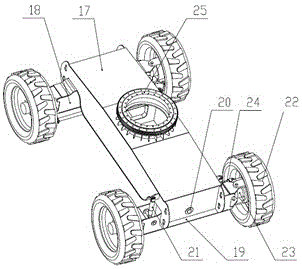

[0031] refer to figure 1 as well as figure 2 , the present embodiment includes a boarding part and a dismounting part, and the boarding part includes a base 1, a boom 2 hinged with the base 1, a telescopic arm 3 slidingly coupled with the boom 2, a small arm 4 and a rotating arm 5; 3. The small arm 4 and the rotating arm 5 are connected end to end in sequence; the small arm 4 and the rotating arm 5 are connected through the rotating arm slewing bearing 6; The plane is always kept vertical; the end of the rotating arm 5 is provided with a gripper 7; the rotating arm 5 and the gripper 7 are connected through the gripper slewing bearing 8; the angle between the rotation center line of the gripper 7 and the rotating arm 5 is zero. Driven by the gripper slewing bearing 8, the gripper 7 can realize 360-degree rotation, realize rapid positioning, and improve gripping efficiency.

[0032] One end of the rotary arm slewing support 6 is hinged with the forearm 4, and the other end i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com