Mounting bracket for mounting engine to left suspension

A technology of mounting bracket and left suspension, which is applied in the direction of power plant, transportation and packaging, jet propulsion device, etc., and can solve the requirements that affect the strength of the engine mounting bracket, the layout structure requirements, the structure design of the engine mounting bracket cannot be satisfied, and the whole vehicle Performance impact and other issues, to achieve the effect of improving mechanical properties and pass rate, increasing service life, and compact use strength requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

[0019] The present invention adopts the following technical solutions:

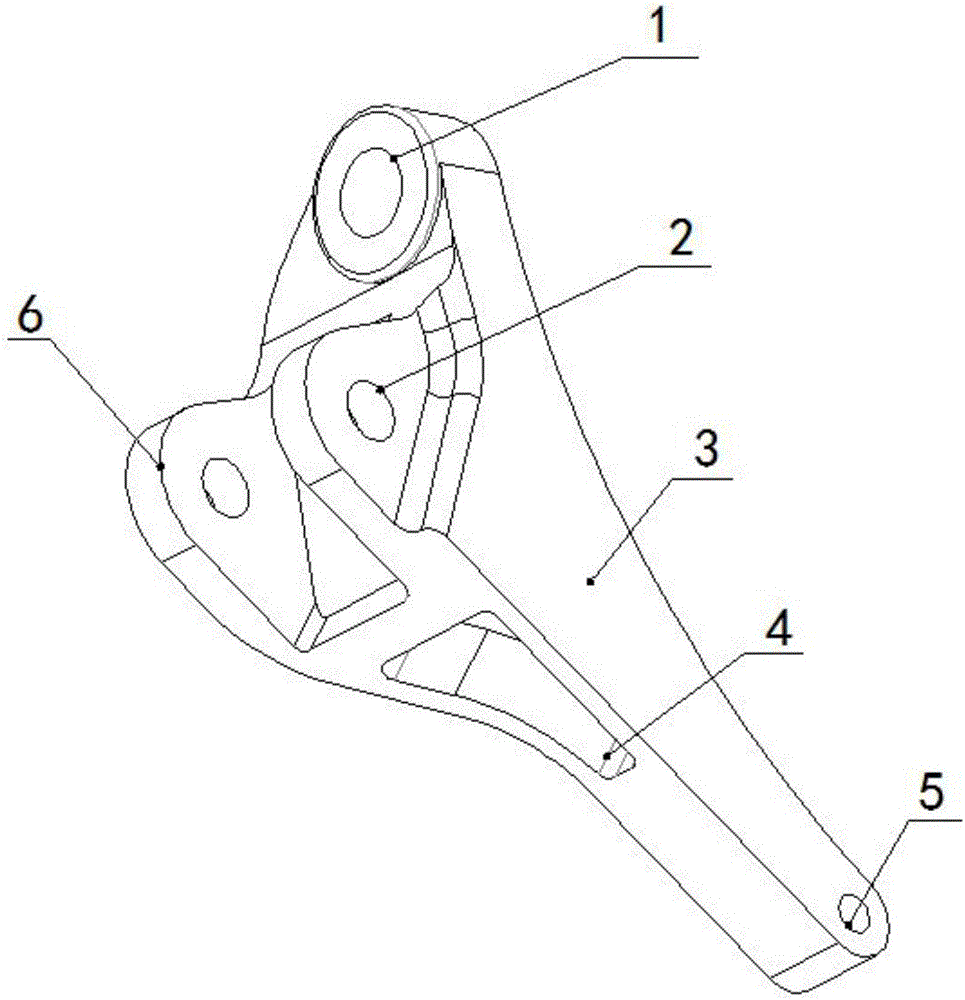

[0020] A left-mounted engine mounting bracket, comprising: a connecting rod 3, the top of the connecting rod 3 is provided with a left-mounted anti-rotation hole 1 for fixing anti-rotation, and anti-rotation bolts can be installed in the holes to prevent tightening of nuts When the engine suspension rotates under the action of the tightening force, the rear part of the connecting rod 3 is provided with a left suspension connecting hole 5 to realize the assembly connection of the left suspension engine mounting bracket and the vehicle body; the middle part of the connecting rod 3 is provided with Cavity 4, two arc-shaped lugs 6 are arranged between the cavity 4 and the left suspension anti-rotation hole 1, and a left suspension mounting hole 2 is provided on each of the two lugs 6,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com