Assembling device of biological reagent plate

A technology for assembling equipment and biological reagents, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of low production efficiency of manual assembly, unstable product quality, product quality problems, etc., to improve product production quality and reduce leakage. The effect of detecting secondary pollution and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

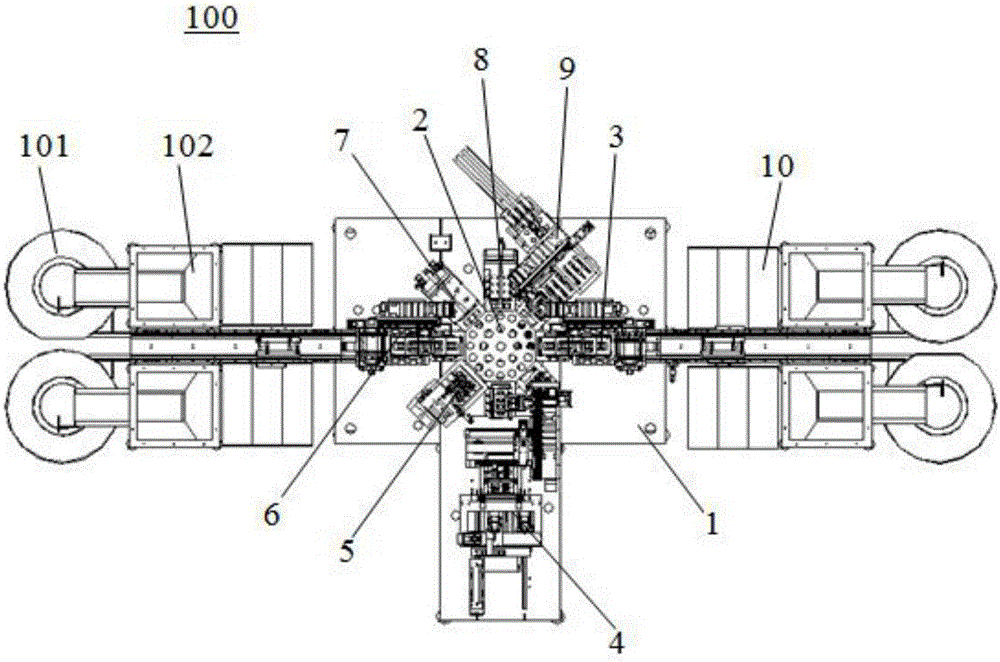

[0055] Please refer to figure 1 , the present embodiment is an assembly device 100 for a biological reagent plate, which includes a machine platform 1, a rotary conveying device 2 fixed on the machine platform 1, and a lower casing arranged clockwise or counterclockwise around the edge of the rotary conveying device 2 Feeding device 3 , reagent strip rolling cutting and feeding device 4 , reagent strip assembly and detection device 5 , upper shell loading device 6 , upper and lower shell pressing devices 7 , pressing height detection 8 and unloading device 9 . One end of the lower casing feeding device 3 and the upper casing feeding device 6 is provided with a feeding device 10 .

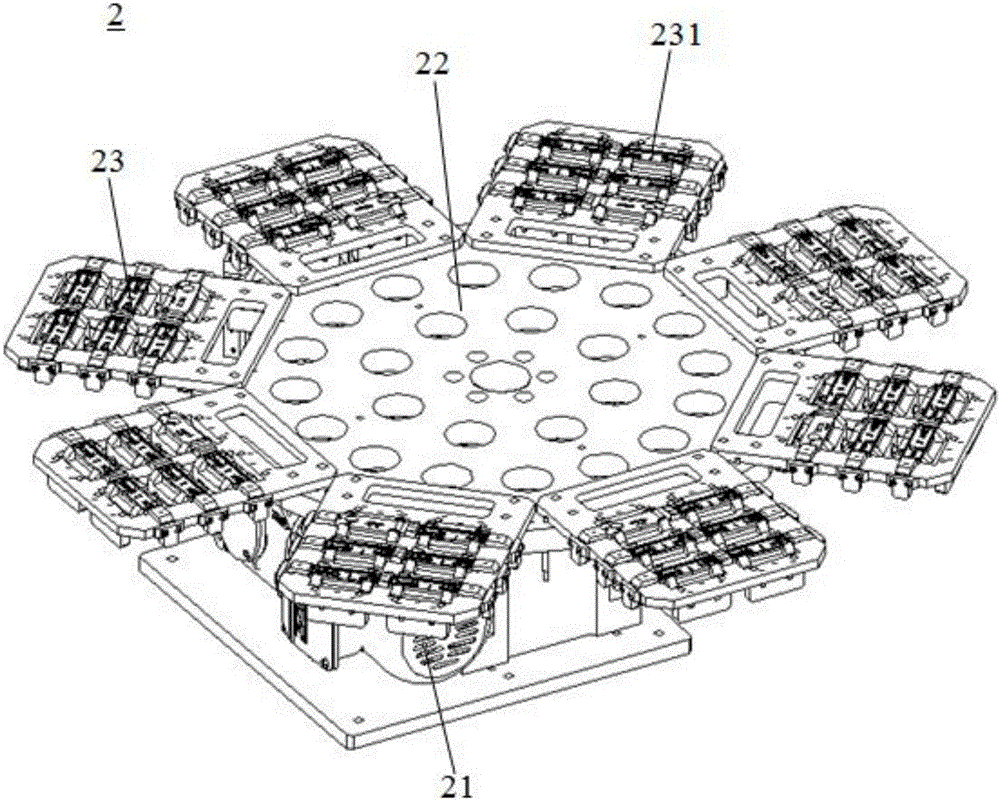

[0056] Please refer to figure 2 The rotary conveying device 2 includes a first drive member 21 fixed below the machine table 1 , a turntable 22 driven by the first drive member 21 to rotate at an equal angle, and a carrier 23 fixed on the surface of the turntable 22 at an equal angle. The carrier...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com