Cutting jig frame for toothed plate of pile leg

A toothed plate and tire frame technology, which is applied in the direction of welding/welding/cutting articles, gas flame welding equipment, manufacturing tools, etc., can solve the problems that the dimensional accuracy cannot meet the precision requirements of the main side tube, and the cutting deformation of the toothed plate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

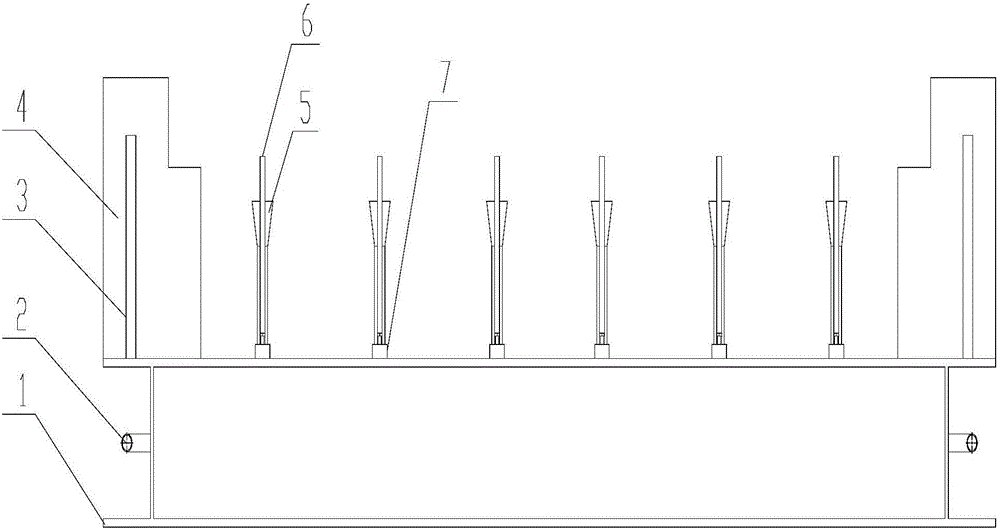

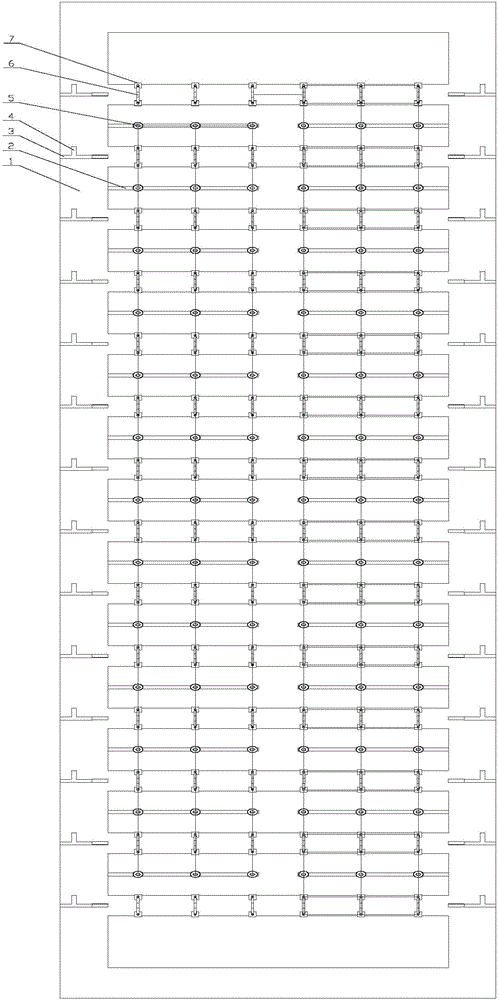

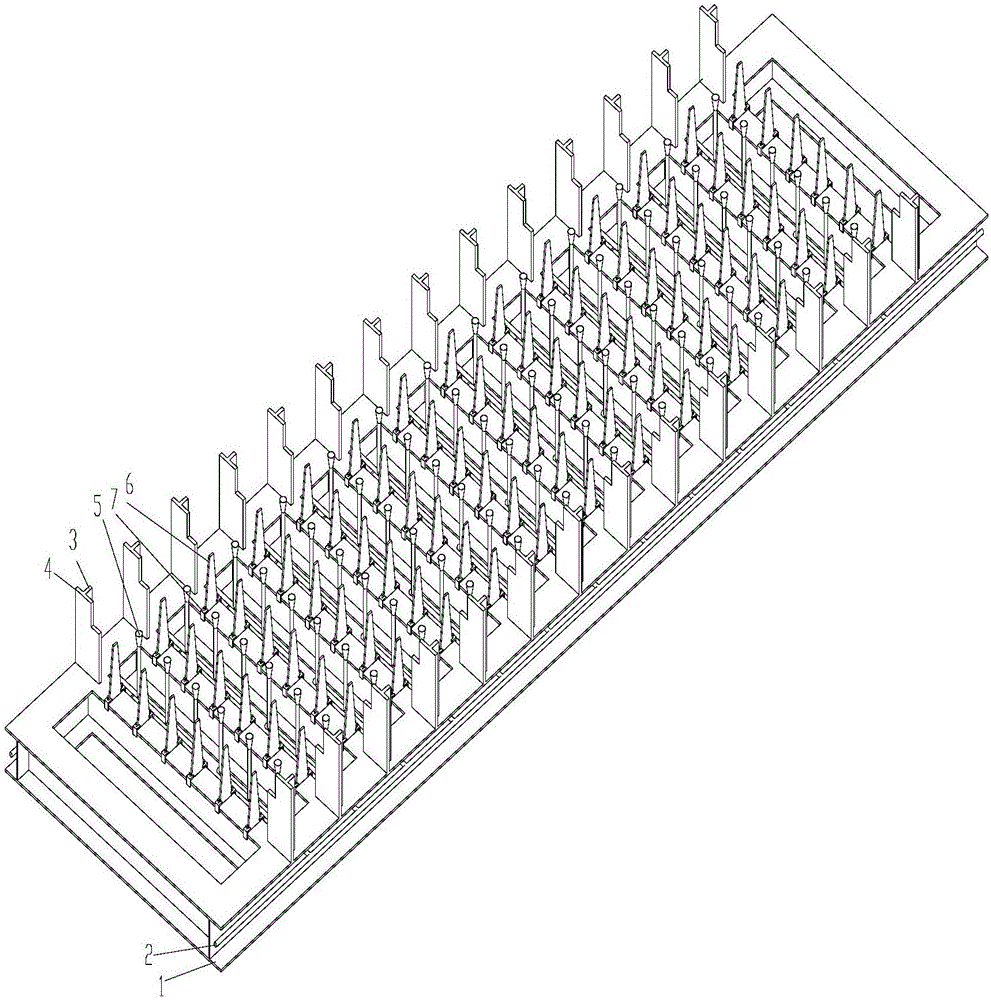

[0017] The present invention includes a base 1, a gas pipeline 2, a fixed rib 3, a support rib 4, a gas nozzle 5, a support vertical plate 6, and a sliding locking structure 7;

[0018] The base 1 is a cuboid, and the surface is provided with a plurality of evenly distributed cuboid grooves running through the top and bottom along the wide side of the base 1, and the top surface of the base 1 between two adjacent cuboid grooves slides The connection is provided with a plurality of sliding locking structures 7, and the top of the sliding locking structures 7 is fixedly connected with a plurality of supporting vertical plates 6 arranged in a straight line, and the supporting vertical plates 6 are all perpendicular to the broad side of the base 1; 1. The top surfaces of the two long sides are uniformly welded and fixed with a plurality of supporting ribs 4, and the supporting ribs 4 are perpendicular to the long sides of the base 1; 6 are in the same straight line; one side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com