Metal workpiece machining device

A technology for processing devices and metal workpieces, which is applied to metal processing equipment, attachments of shearing machines, pipe shearing devices, etc., can solve the problems of axial deviation of pipe fittings, large diameter of pipe fittings, and troublesome problems, so as to achieve uniform reaction force, Guaranteed cutting size and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

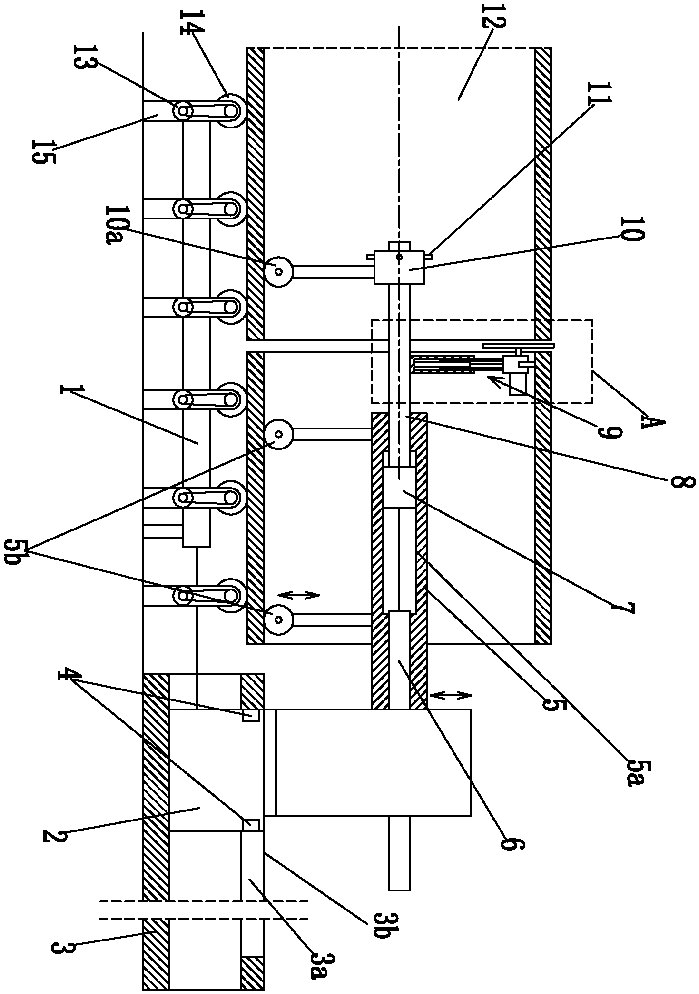

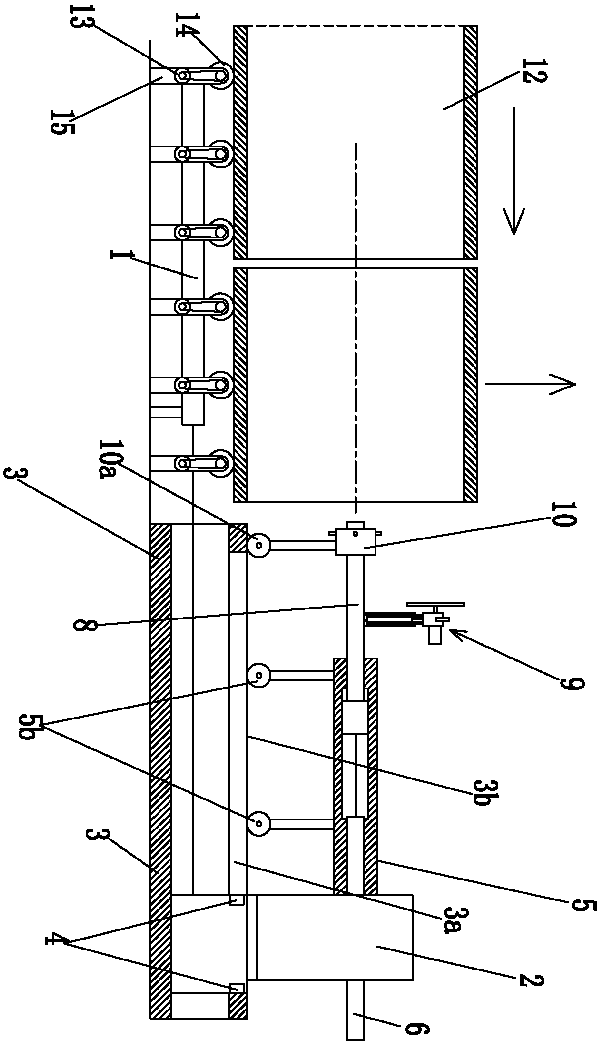

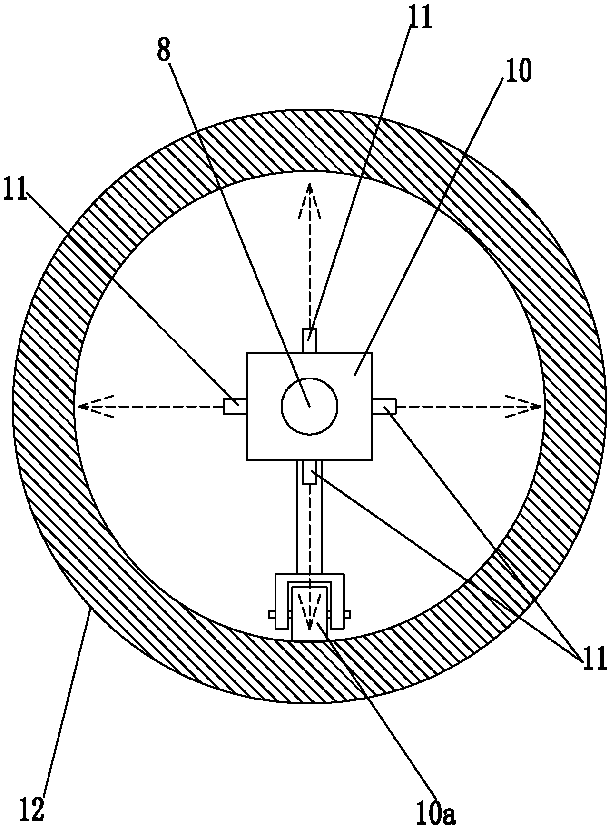

[0020] Such as Figure 1-5 As shown, a metal workpiece processing device includes a translational conveying mechanism for horizontally placing the pipe fitting 12, supporting the outer peripheral wall of the pipe fitting 12, and driving the pipe fitting 12 to translate along its axis direction, and also includes a translation conveying mechanism with the translation conveying mechanism The base seat 3 corresponding to the position also includes the main slide seat 2 which can be horizontally slidably installed on the base seat 3, and the sliding direction is adapted to the translation direction of the pipe fitting 12, and also includes a main slide seat 2 for driving the main slide seat 2 to slide. The primary drive cylinder 1 also includes a PLC controller 16 , and the base 3 is provided with a reference plane 3 b whose height matches the height of the bottom of the inner peripheral wall of the pipe fitting 12 .

[0021] The above-mentioned main sliding seat 2 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com