Caramel treats and preparation method thereof

A technology of raw materials and parts by weight, which is applied in the field of Shaqima and its preparation, can solve the problems of unable to meet people's needs, high fat and sugar content, unfavorable nutrition and health, etc., and achieve the convenience of large-scale production, fat and sugar content Low content, unique taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

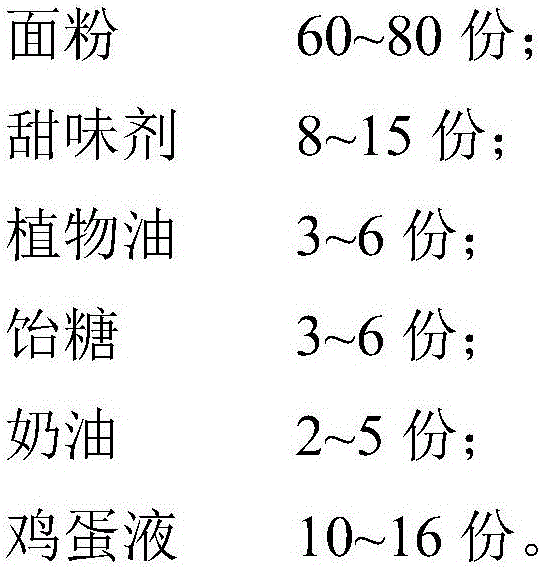

[0024] In parts by weight, the raw materials are composed as follows:

[0025]

[0026] (1) According to the above ratio, mix flour, xylitol, peanut oil, sodium bicarbonate, egg liquid, and cream, add water and stir evenly, then make leather, proof at a temperature of 60°C and a humidity of 80% for 4 hours, and press it into Dough shape, then cut into particles;

[0027] (2) Fry the cut granules at an oil temperature of 175°C for 5 minutes to obtain semi-finished granules, which are golden yellow and must not appear brown or reddish brown;

[0028] (3) boil the caramel at a temperature of 150° C. for 4 hours;

[0029] (4) Pour the fried granules into the boiled caramel, stir for 20 seconds, and quickly pour them into the molding box to form.

Embodiment 2

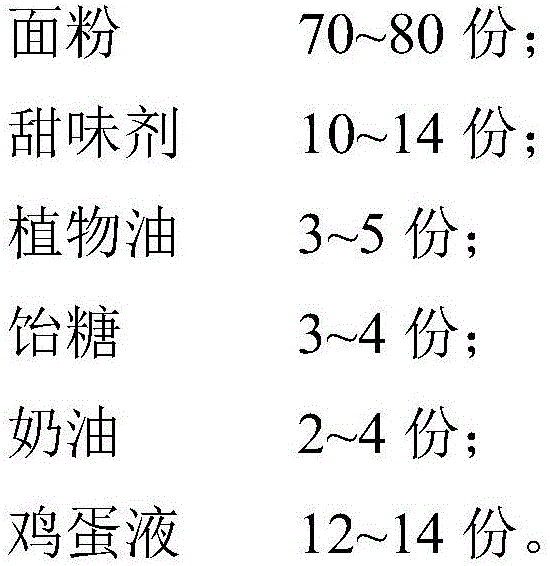

[0031] In parts by weight, the raw materials are composed as follows:

[0032]

[0033] (1) According to the above ratio, mix flour, xylitol, peanut oil, sodium bicarbonate, egg liquid and cream, add water and stir evenly, then make leather, proof at a temperature of 55°C and a humidity of 80% for 5 hours, and press it into Dough shape, then cut into particles;

[0034] (2) Fry the cut granules at an oil temperature of 175°C for 5 minutes to obtain semi-finished granules, which are golden yellow and must not appear brown or reddish brown;

[0035] (3) boil the caramel at a temperature of 140° C. for 5 hours;

[0036] (4) Pour the fried granules into the boiled caramel, stir for 15 seconds, and quickly pour them into the molding box to form.

Embodiment 3

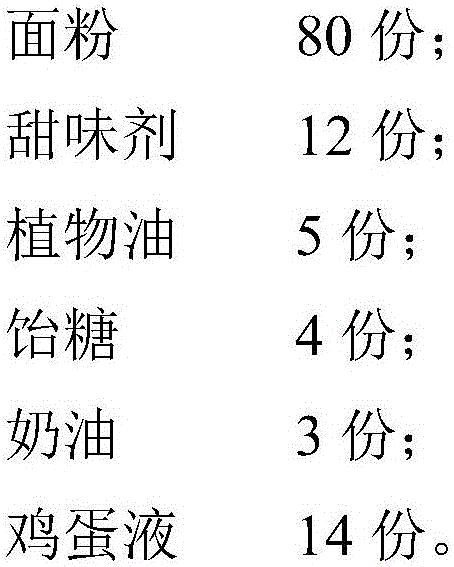

[0038] In parts by weight, the raw materials are composed as follows:

[0039]

[0040] (1) According to the above ratio, mix flour, xylitol, peanut oil, sodium bicarbonate, egg liquid and cream, add water and stir evenly, then make leather, proof for 3 hours at a temperature of 65°C and a humidity of 75%, and press it into Dough shape, then cut into particles;

[0041] (2) Fry the cut granules at an oil temperature of 175°C for 5 minutes to obtain semi-finished granules, which are golden yellow and must not appear brown or reddish brown;

[0042] (3) boil the caramel at a temperature of 150° C. for 3 hours;

[0043] (4) Pour the fried granules into the boiled caramel, stir for 20 seconds, and quickly pour them into the molding box to form.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com