Solar cell reworking sheet coating technology

A solar cell and process technology, which is applied to circuits, electrical components, sustainable manufacturing/processing, etc., can solve the problems of prone to dark etching, dirty chips or uneven diffusion of coatings, and obvious differences in polycrystalline silicon wafers. Achieve the effect of reducing variance and improving appearance yield

Inactive Publication Date: 2016-11-09

ALTUSVIA ENERGY TAICANG

View PDF3 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] In the industrial production of the traditional preparation process of crystalline silicon solar cells, due to the operation of personnel or equipment abnormalities during the process, dirty chips or coatings and uneven diffusion are often produced. These silicon chips are defective products and usually need to be remanufactured. cashmere rework

Polysilicon wafers usually use HF and HNO 3 Mixed acid etching process, after rework and texturing, the crystal flower difference of polycrystalline silicon wafers will become more obvious, and etching dark lines are prone to appear

These appearance phenomena cannot be completely eliminated in the follow-up conventional process, and the finally formed cells with poor appearance can only be treated as unqualified products

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0026] The coating experiment was carried out using the process parameters in Table 1 below.

[0027] Table 1

[0028]

Embodiment 2

[0030] The coating experiment was carried out using the process parameters in Table 2 below.

[0031] Table 2

[0032]

Embodiment 3

[0034] The coating experiment was carried out using the process parameters in Table 3 below.

[0035] table 3

[0036]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

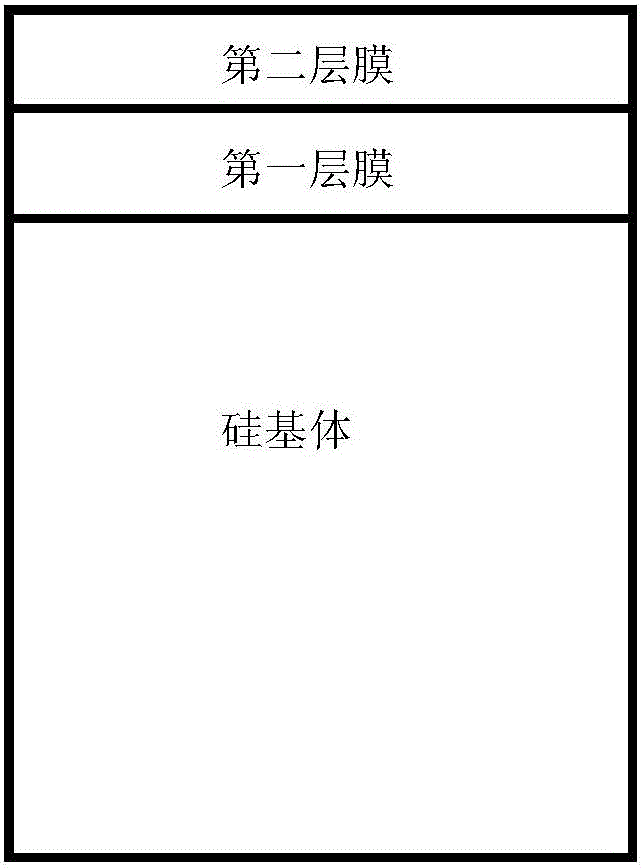

A solar cell reworking sheet coating technology employs a bilayer film technology. The refractive index of a first layer film is higher than the refractive index of a second layer film, and the thickness of the first layer film is 25-40mm. The technology provided by the invention can effectively reduce the proportion of bad cell appearances caused by re-flocking.

Description

technical field [0001] The invention belongs to the technical field of photovoltaics, in particular to a coating process for reworked solar cell sheets. Background technique [0002] Solar energy is an inexhaustible renewable energy source for human beings, and it is also a clean energy source that does not produce any environmental pollution. Among the effective utilization of solar energy, solar photovoltaic utilization is the fastest-growing and most dynamic research field in recent years, and it is one of the most watched projects. To this end, people have researched and developed solar cells. The production of solar cells is mainly based on semiconductor materials, and its working principle is to use photoelectric materials to absorb light energy and generate photoelectric conversion reactions. According to the different materials used, it can be divided into: silicon solar cells; cells made of inorganic salts such as gallium arsenide III-V compounds, cadmium tellurid...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01L31/18

CPCH01L31/18Y02P70/50

Inventor 陈文浩王冕奚彬刘仁中

Owner ALTUSVIA ENERGY TAICANG

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com