Barrier probe provided with solid dielectric film on probe point

A dielectric and conductive probe technology, applied in the field of potential barrier probes, can solve the problems of easy falling off, inability to be applied, weak adsorption force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Barrier probe fabricated by depositing a solid dielectric film on the tip of a platinum-iridium alloy probe

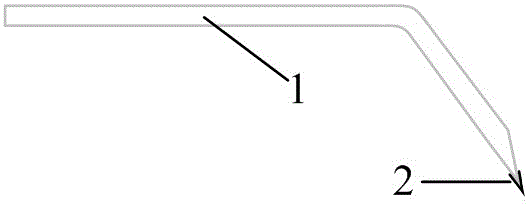

[0048] First, cut out a sharp conductive tip from one end of a platinum-iridium alloy wire with a length of about 10 mm and a diameter of 0.15 mm with pliers or scissors to form a conductive probe 1, and then deposit a layer on the conductive tip of the conductive probe 1. A silicon dioxide solid dielectric film 2 with a thickness of about 10 nm is enough.

Embodiment 2

[0050] Barrier probe fabricated by depositing a solid dielectric film on a curved platinum-iridium alloy probe tip

[0051] In embodiment 1, it is sufficient to fold the platinum-iridium alloy wire into an angle of about 110° at a place about 2 mm behind the conductive tip of the conductive probe 1 . Since the probe of the scanning tunneling microscope does not need to vibrate, it is not necessary for the conductive probe to have excellent vibration stability.

Embodiment 3

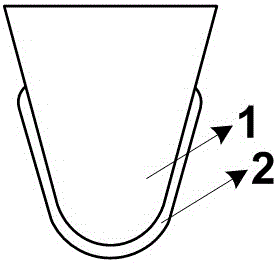

[0053] Barrier probe made by depositing solid dielectric thin film at the tip of CAFM probe

[0054] First find a probe for CAFM, and deposit a layer of silicon dioxide solid dielectric film with a thickness of about 10 nm on the conductive tip of the probe.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com