Miniature ultraviolet-visible/infrared nondestructive test spectrometer

An infrared non-destructive testing and spectrometer technology, applied in the field of optical instruments, can solve problems such as large measurement error, unsatisfactory spectral resolution, and increased system complexity, achieving good anti-interference and stability, ideal spectral resolution, and convenience. The effect of promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

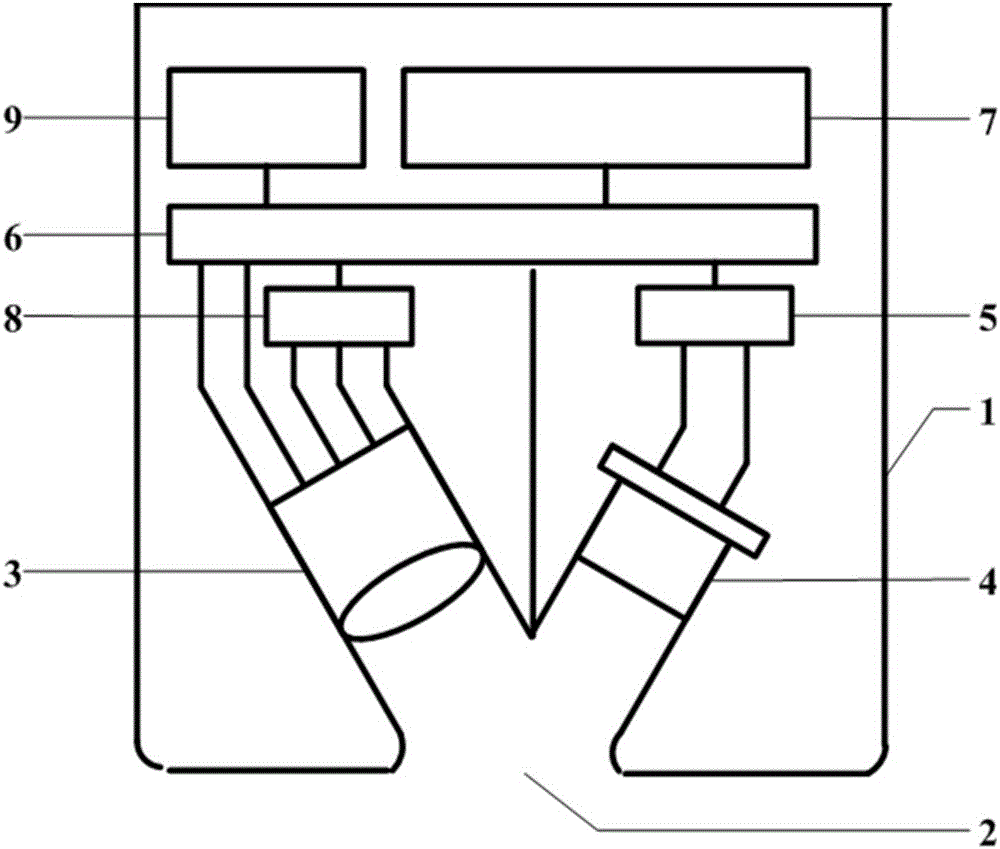

[0032] Example 1 Reflective multi-wavelength miniature ultraviolet-visible / infrared non-destructive testing spectrometer

[0033] The light source 3, photoelectric sensor 4, circuit system and power supply 9 of a miniature ultraviolet-visible / infrared nondestructive testing spectrometer are all installed in the casing 1 (see figure 1 , 3 -4). The light source 3, the irradiation center point, and the photoelectric sensor 4 are located on the same plane, and the angles between the light output path of the light source 3, the detection path of the photoelectric sensor 4, and the normal line of the irradiation center point are equal to ensure that the reflected light enters the photoelectric sensor 4 to the maximum extent. .

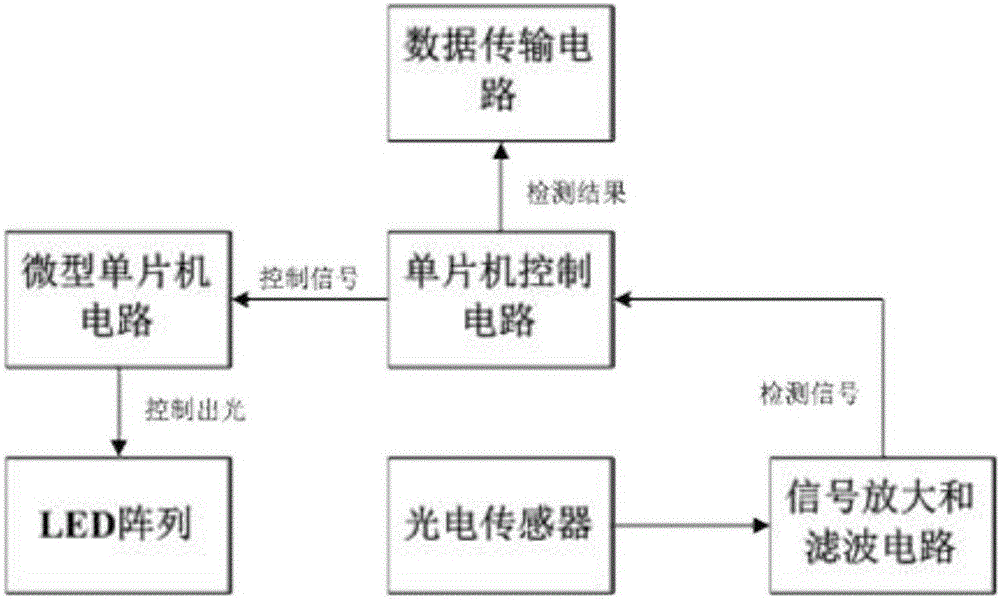

[0034] The light source 3 includes pins, tube sockets, aluminum substrates, micro-single-chip microcomputer circuits, LED arrays, light guides and light guide tubes (see Figure 5 ). The pins include two voltage supply pins, common ground pins, data tran...

Embodiment 2

[0040] Example 2 Reflective dual-wavelength miniature ultraviolet-visible / infrared nondestructive testing spectrometer

[0041] The light source 3, photoelectric sensor 4, circuit system and power supply 9 of a miniature ultraviolet-visible / infrared nondestructive testing spectrometer are all installed in the casing 1 (see Figure 3-4 ). The light source 3, the irradiation center point, and the photoelectric sensor 4 are located on the same plane, and the angles between the light output path of the light source 3, the detection path of the photoelectric sensor 4, and the normal line of the irradiation center point are equal to ensure that the reflected light enters the photoelectric sensor 4 to the maximum extent. .

[0042] The light source 3 includes pins, tube sockets, aluminum substrates, micro-single-chip microcomputer circuits, LED arrays, light guides and light guide tubes (see Figure 5 ). The pins include two voltage supply pins, common ground pins, data transmissi...

Embodiment 3

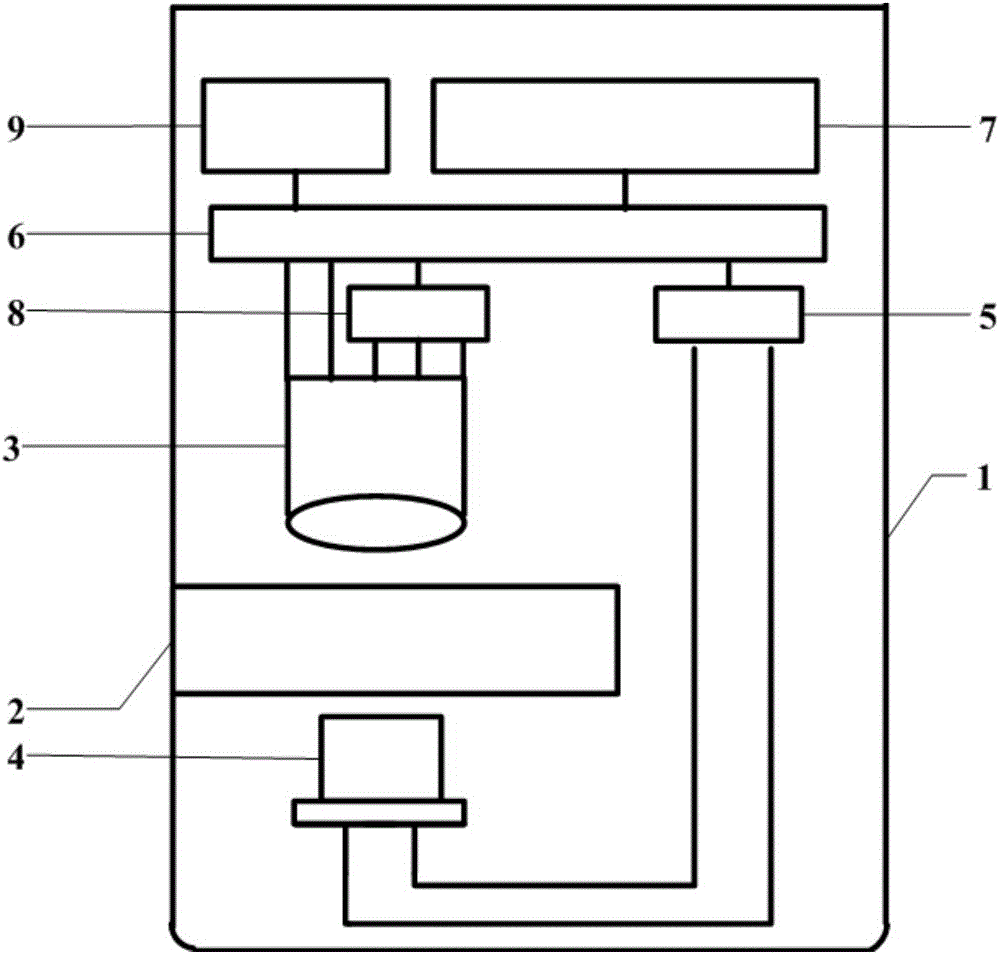

[0048] Example 3 Transmissive multi-wavelength miniature ultraviolet-visible / infrared non-destructive testing spectrometer

[0049] The light source 3, photoelectric sensor 4, circuit system and power supply 9 of a miniature ultraviolet-visible / infrared nondestructive testing spectrometer are all installed in the casing 1 (see Figure 2-4 ). The light source 3, the central point of irradiation and the photoelectric sensor 4 are located on the same plane, and the light output path of the light source 3, the detection path of the photoelectric sensor 4, and the central point of irradiation are on the same straight line to ensure that the transmitted light enters the photoelectric sensor 4 to the maximum extent.

[0050] The light source 3 includes pins, tube sockets, aluminum substrates, micro-single-chip microcomputer circuits, LED arrays, light guides and light guide tubes (see Figure 5 ). The pins include two voltage supply pins, common ground pins, data transmission pins ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com