Combined type intelligent electroslag system

A combined, electroslag technology, applied in furnace components, furnace cooling, lighting and heating equipment, etc., can solve the problems of inconvenient use of slag furnaces, increased production costs, low production costs, etc., and achieves ingenious structural design and improved The effect of production efficiency and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

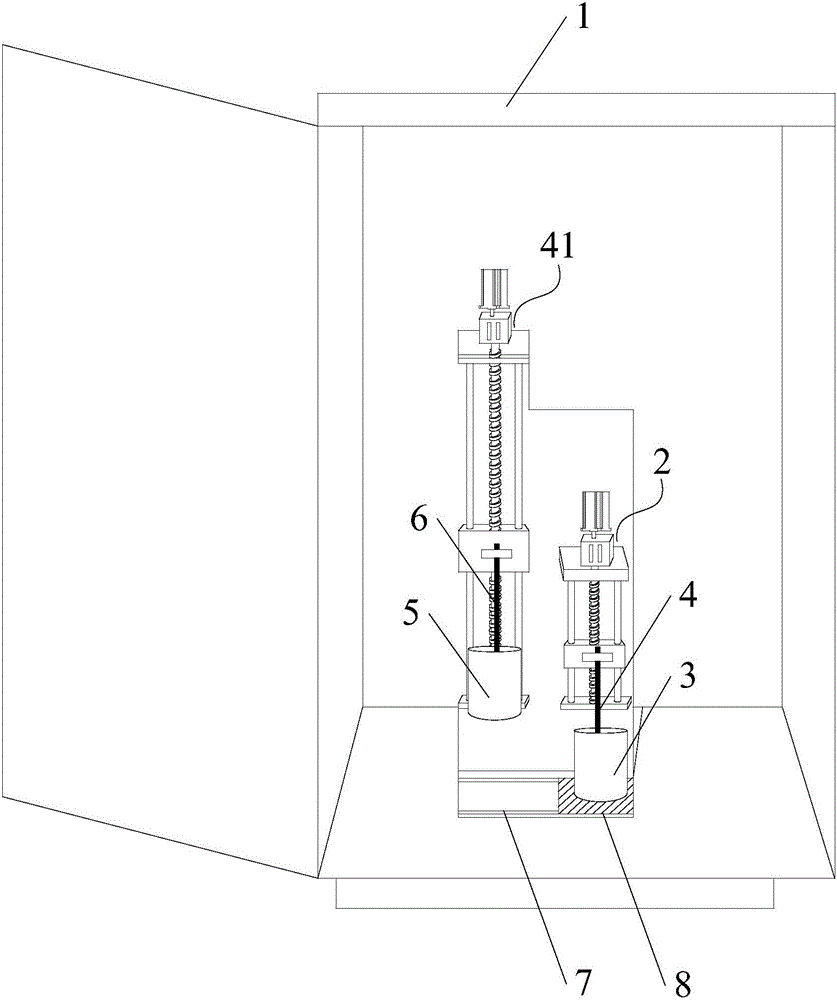

[0039] Such as figure 1 As shown, Embodiment 1 of the present invention provides a combined intelligent electroslag system, including a sealed box 1, which is used to fill inert gas, so that the electroslag process is completed under a protective atmosphere, making the steel ingot product more pure, In addition, the steelmaking process is completed in the sealed box 1, which can prevent CaF 2 Smoke is harmful to people, and it is safer and more environmentally friendly to use.

[0040] The sealed box 1 is provided with a slag removal assembly and a remelting assembly, and the slag removal assembly includes a slag removal pool 3, a lifting mechanism-2 and a slag removal electrode 4 connected to the lifting mechanism-2. The slag pool 3 is located below the slag removal electrode 4; the lifting mechanism-2 can drive the slag removal electrode 4 to move up and down. The slag constitutes an electrical connection path to carry out the slag removal process. The remelting assembly ...

Embodiment 2

[0044] Such as figure 2 As shown, so the present invention also defines that the electroslag system also includes a controller 9, the controller 9 can realize the intelligent monitoring of the whole system, and the first lifting mechanism 2 and the second lifting mechanism 41 are connected with the controller 9 connection, the controller 9 is used to control the lifting of the first lifting mechanism 2 and the second lifting mechanism 41, so that the first lifting mechanism 2 and the second lifting mechanism 41 drive the slag slag electrode 4 and the second lifting mechanism respectively. The remelting electrode 6 moves up and down.

Embodiment 3

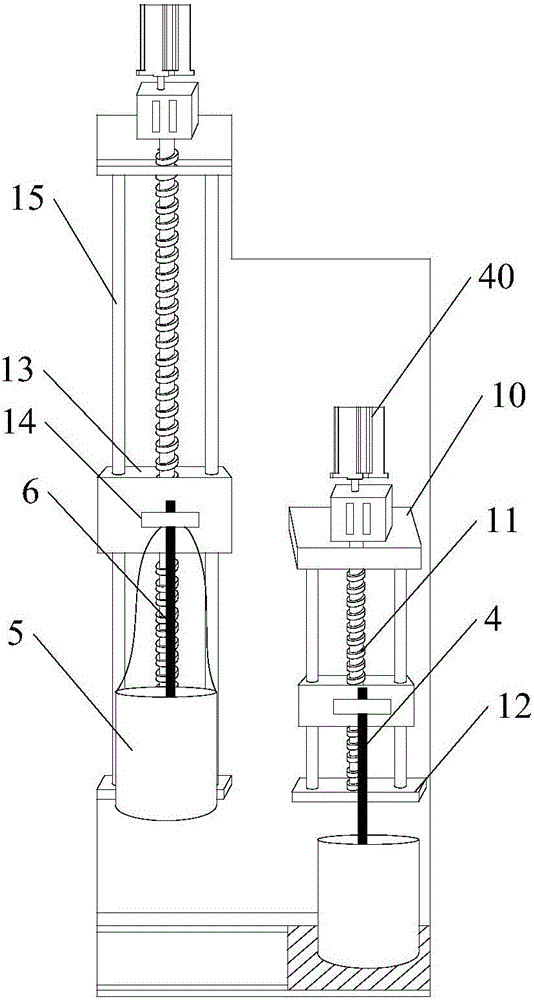

[0046] Embodiment 3 of the present invention provides a combined intelligent electroslag system. On the basis of Embodiment 2, the system further defines the structures of the first lifting mechanism 2 and the second lifting mechanism 41, which improves the practicability.

[0047] Such as image 3 As shown, it should be noted that the lifting mechanism 1 2 and the lifting mechanism 2 41 both include a support plate 10, a support plate 12 and a support plate fixed longitudinally between the support plate 10 and the support plate 2 12. Between the screw 11, the middle part of the support plate 10 and the support plate 12 has a through hole, the two ends of the screw 11 are connected in the through hole and pivotally connected with the through hole through the bushing or the bearing, that is to say, the screw The bar 11 can rotate relative to the first support plate 10 and the second support plate 12 . The top of the leading screw 11 is connected to the motor 40 connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com