Heat recovering and preheating device for dryer

A technology of preheating device and heat recovery, applied in dryers, drying, dryer combinations, etc., can solve the problems of affecting the economic benefits of tea enterprises, unfavorable energy saving and consumption reduction of tea enterprises, and long drying time of tea leaves, etc. Fast and efficient heat transfer, improved efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

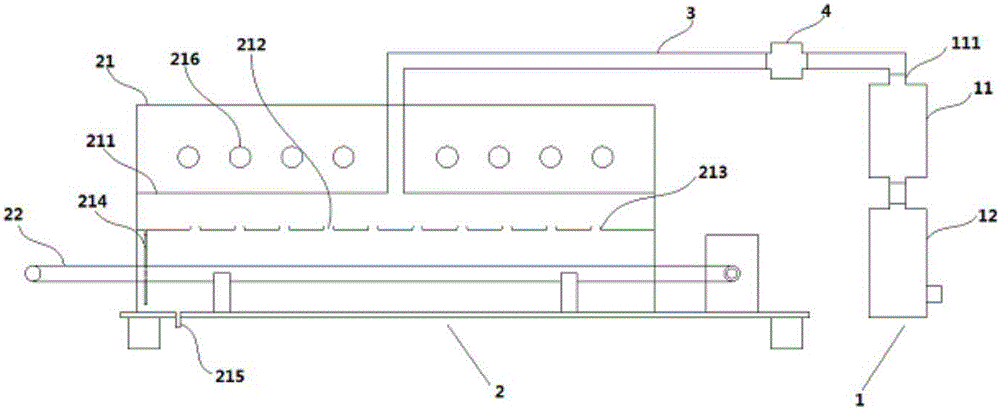

[0016] A heat recovery preheating device for a dryer, such as figure 1 As shown, it includes a dryer 1 and a preheating device 2. The dryer 1 is composed of an oven 11 and a hot blast furnace 12. The preheating device 2 is composed of a preheating box 21 and a conveyor belt 22. The conveyor 22 is located at the bottom of the preheating box 21 and runs through the preheating box 21. , the top of the preheating box 21 is provided with a heat storage bin 211, the bottom of the heat storage bin 211 is provided with an air hole 212, and the surrounding holes of the air hole 212 protrude upwards along the 213, and the bottom of the heat storage bin 211 is provided with a drain pipe 214 for drainage. The pipe 214 is connected to the bottom of the preheating box 21, the bottom of the preheating box 21 is provided with a drainage hole 215, the heat storage bin 211 is connected with the exhaust pipe 111 of the oven 11 through the pipeline 3, and the side walls around the preheating box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com