Metallic inner-thread water pipe joint facilitating equipotential line connection

A technology of water pipe joints and metal joints, which is applied in the direction of pipes/pipe joints/fittings, threaded connections, passing components, etc. It can solve the problems of complex structure of conductive strips, high processing costs, and wire shedding, etc., and achieves safe and reliable connection structures. Processing The effect of low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

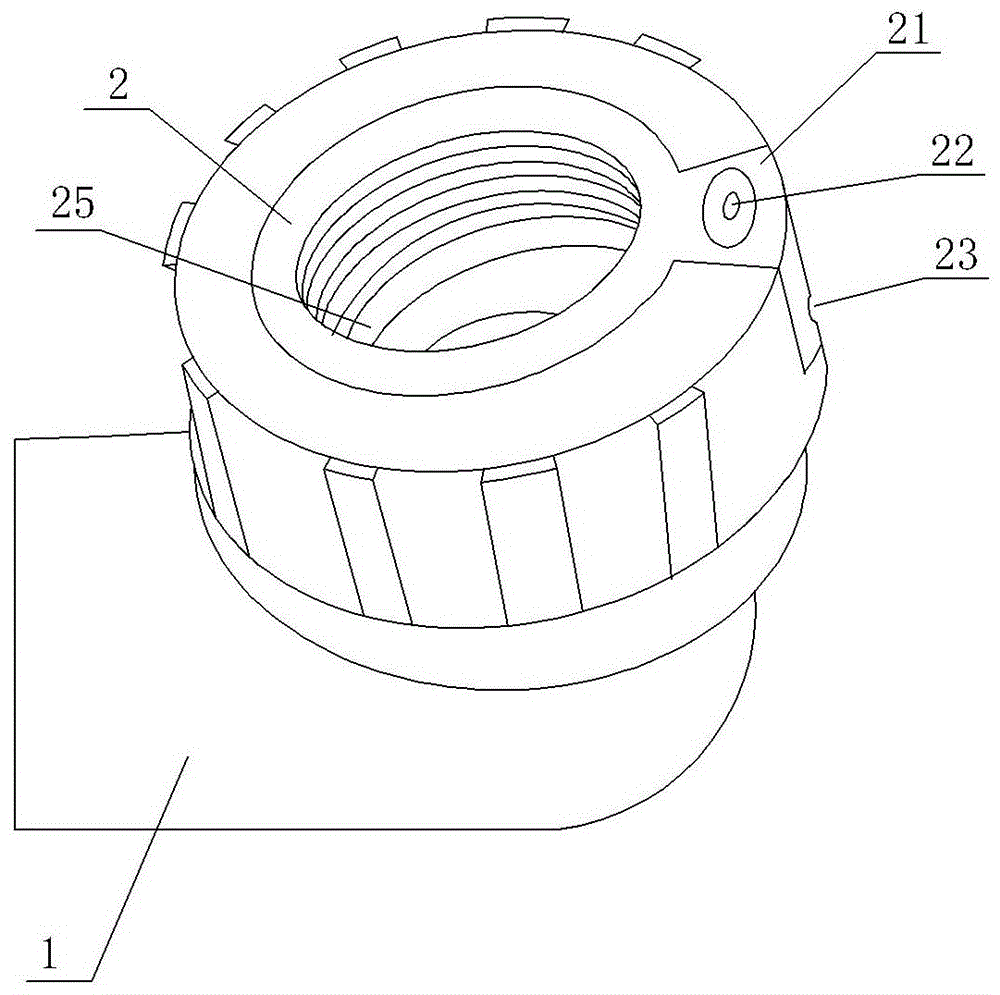

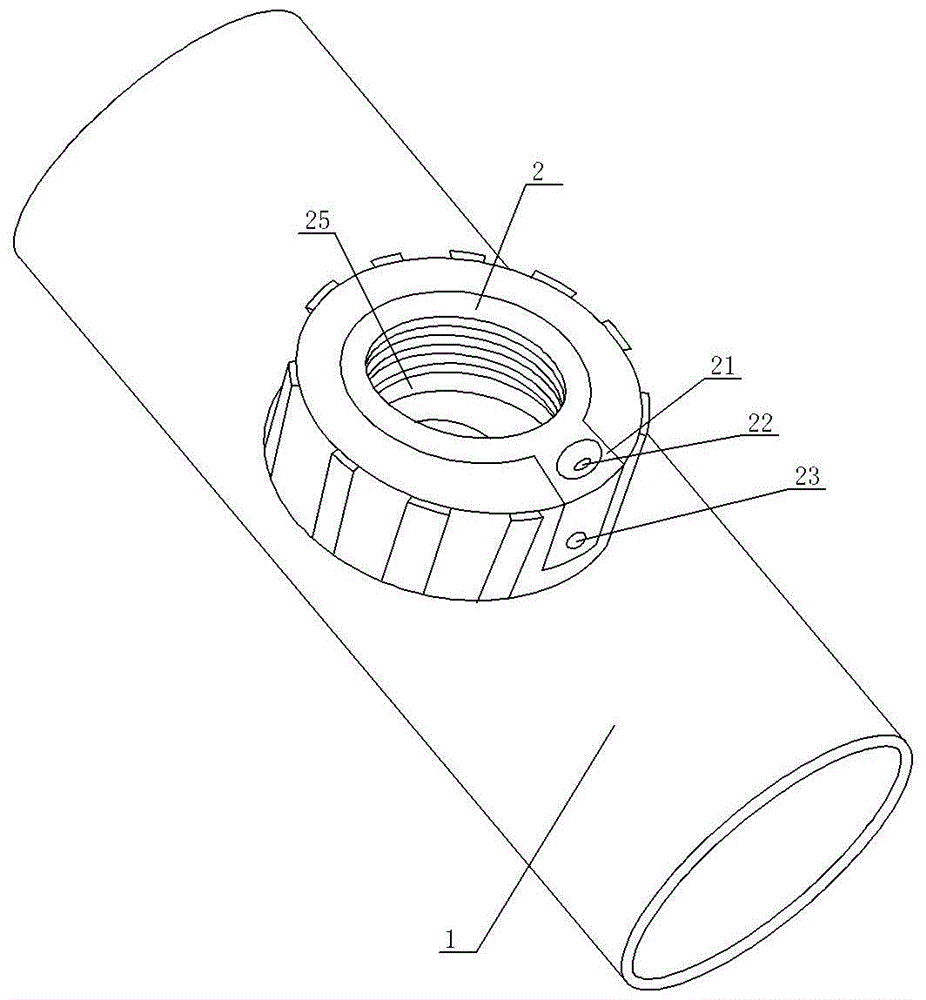

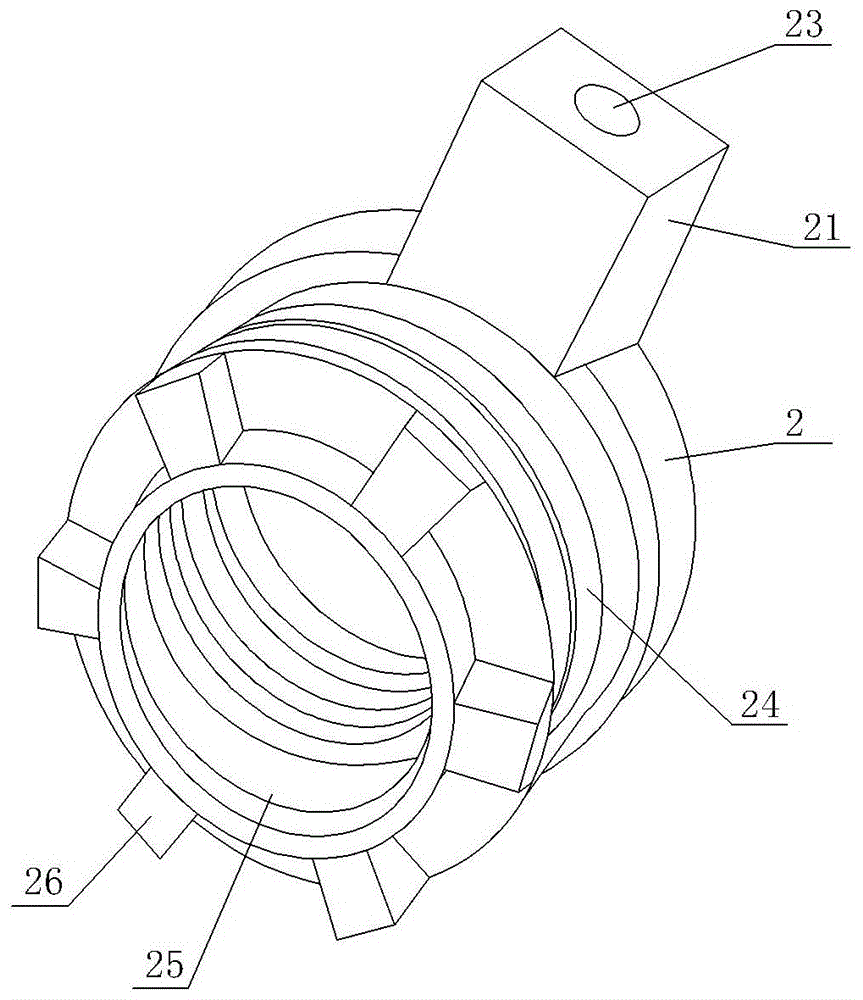

[0019] Implementation one:

[0020] Such as Figure 1-5 As shown, the present invention is a metal inner tooth water pipe joint with convenient equipotential line connection, including a water pipe joint 1 integrally injection-molded with an internal thread metal joint 2, and the outer surface of the internal thread metal joint 2 is integrally provided with a metal bump 21 The outer end surface of the metal bump 21 is provided with a tightening screw hole 22 along the axial direction, and the outer surface of the metal bump 21 is provided with a wiring hole 23 communicating with the inner end of the tightening screw hole 22 along the radial direction. The innermost end is connected with wiring hole 23 at about 2-5 millimeters. During use, one end of wire 3 stretches into wiring hole 23, and then tightens wire 3 from tightening threaded hole 22 by tightening screw 4. Wire 3 has a The small section can be forced into the innermost end of the threaded hole 22, so that the connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com