High-speed magnetic-bearing pneumatic spindle

A technology of magnetic suspension bearing and main shaft, applied in the direction of magnetic bearing, bearing, bearing components, etc., can solve the problems of high cost, technology to be improved, inconvenient operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

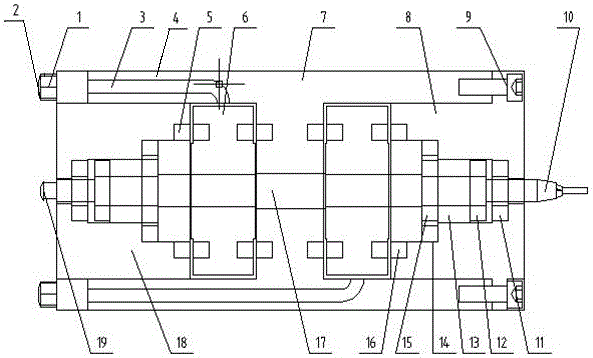

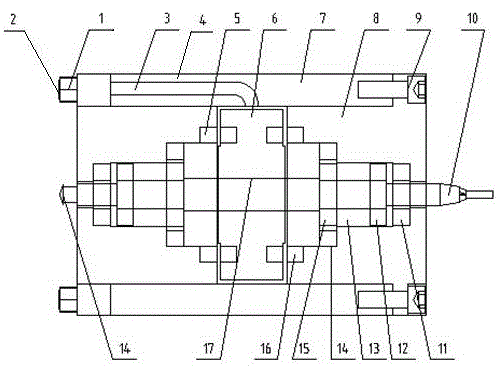

[0006] A preferred embodiment of the present invention, as figure 1 As shown, the high-speed magnetic suspension bearing pneumatic spindle is composed of a shell 5, a hollow shaft 15, front and rear end covers 6, 16, two air wheels 4, 18 and 16 annular permanent magnets. The shell is cylindrical, and the inner diameter of the shell and Ring-shaped permanent magnets are installed correspondingly on the outer diameter of the inner shaft, and the permanent magnets 9, 12, and 14 are respectively embedded in the insides of the front and rear end covers (the front and rear end covers have a symmetrical structure). Ring permanent magnets 10 , 13 are mounted on a hollow shaft 15 . Install permanent magnets 3 on both sides of the gas wheel respectively, and assemble two gas wheels 4 and 18 with permanent magnets into the housing from both sides of the hollow shaft respectively, the space between the magnetic rings 10 and 13 is fixed by the bushing 11, the front and rear ends Covers 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com