Engine air track mounting bracket with vibration attenuation function

A technology for mounting brackets and engines, applied to engine components, combustion engines, machines/engines, etc., can solve the problems of complex assembly, unfavorable mass production, and many parts, and achieve the effect of reducing production costs and improving competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The structure of the present invention is described in detail below in conjunction with accompanying drawing:

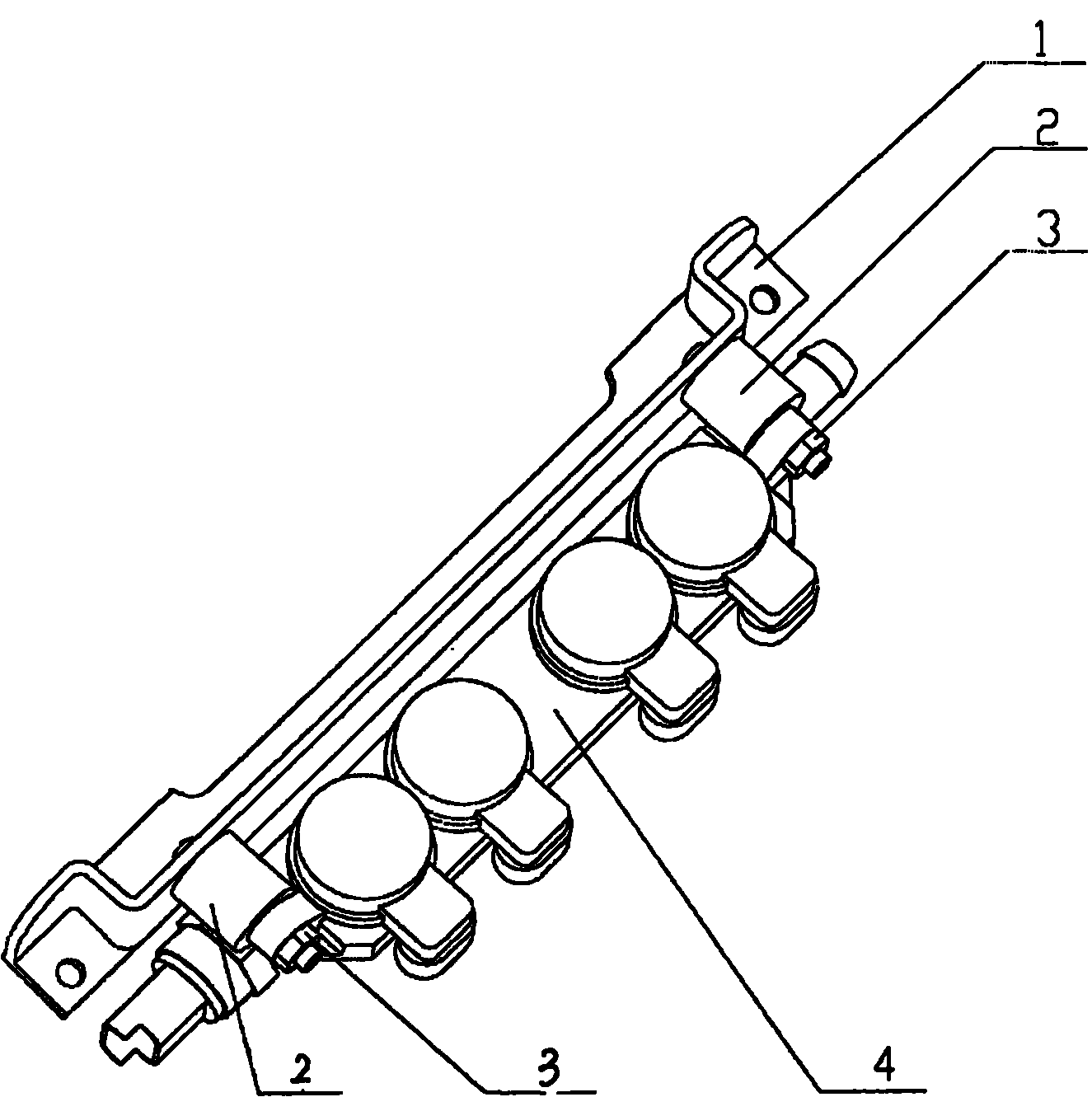

[0016] see figure 1 , the engine air rail mounting bracket includes a bracket 1 and an air rail 4, and the two ends of the air rail 4 are connected to the bracket 1 through a damping unit 2.

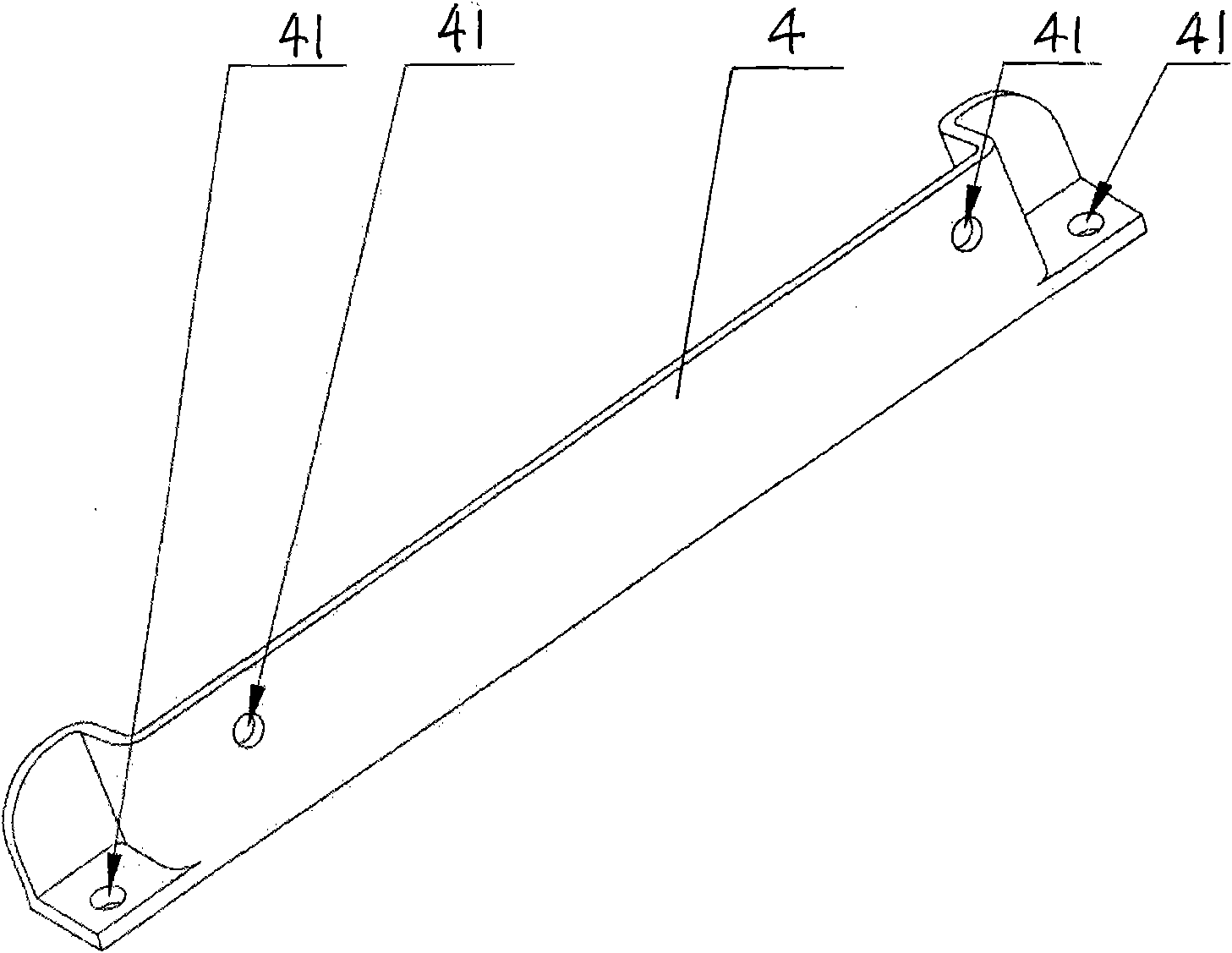

[0017] see figure 2 , the bracket 1 is in the shape of a strip, and there are mounting holes 41 at both ends thereof, which are respectively used for mounting on the engine and mounting the damping unit 2 .

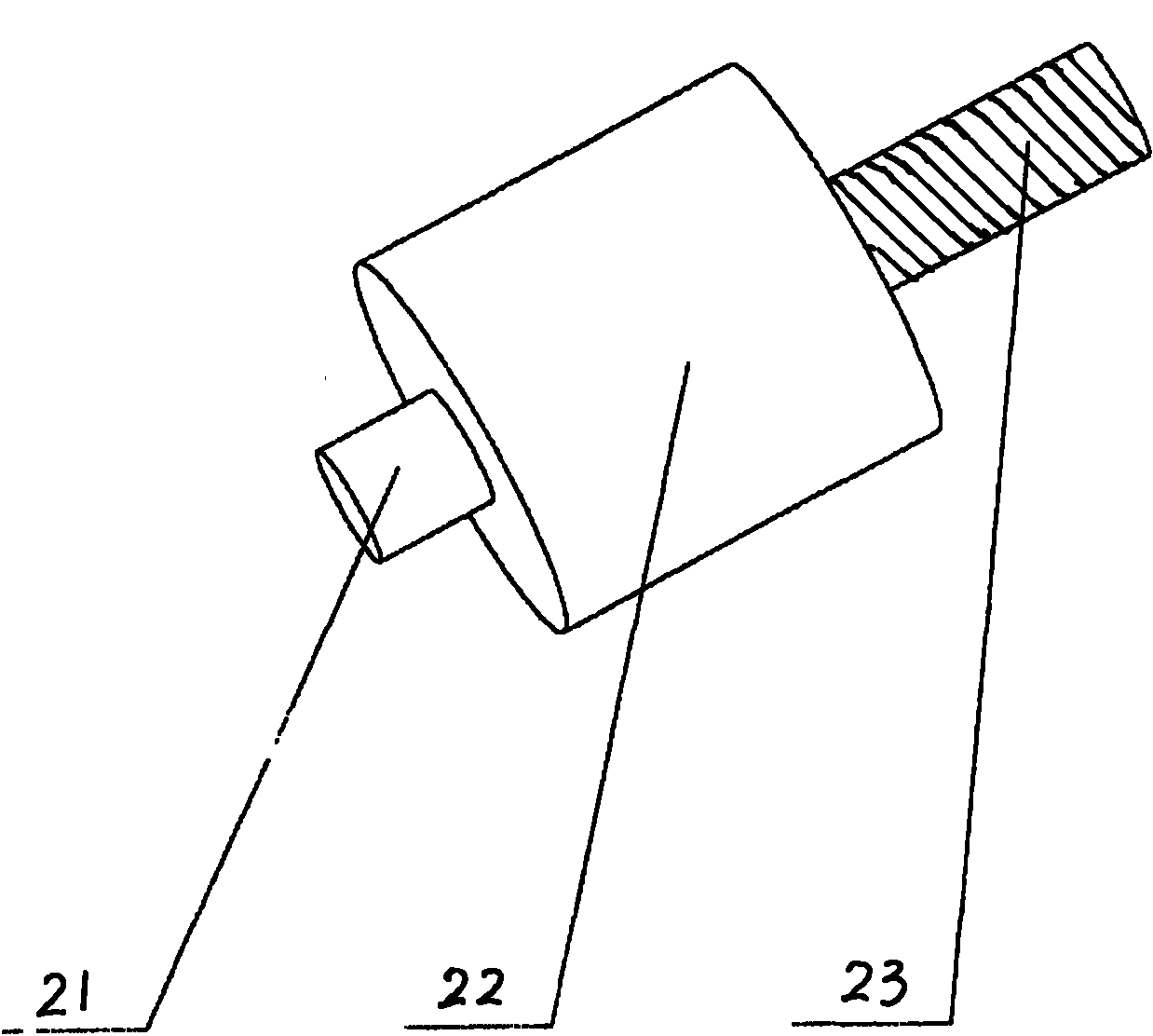

[0018] like image 3 and Figure 4 As shown, the damping unit is made up of a metal polished rod 21, a metal screw 22 and a rubber damping block 23, the rubber damping block 23 is a cylinder, and one end of the metal polished rod 21 and the metal screw 22 is embedded in the rubber damping block 23 respectively. Both ends, but not through the rubber damping block 23, the other ends of the metal polished rod 21 and the metal screw 22 are exposed respectively, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com