Novel drilling mud pump

A drilling mud, a new type of technology, applied in the direction of pumps, multi-cylinder pumps, piston pumps, etc., can solve the problems of reducing transmission efficiency and working reliability, increasing pump volume and weight, and increasing the weight of mud pumps. It achieves compact structure, Effect of reducing maintenance cost and reducing mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

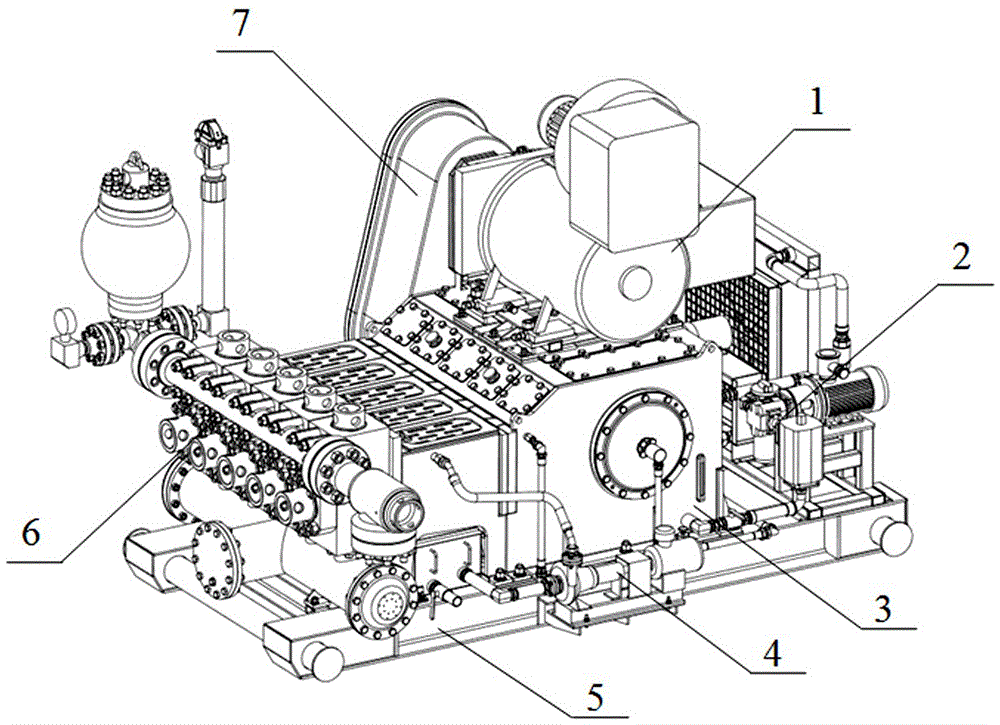

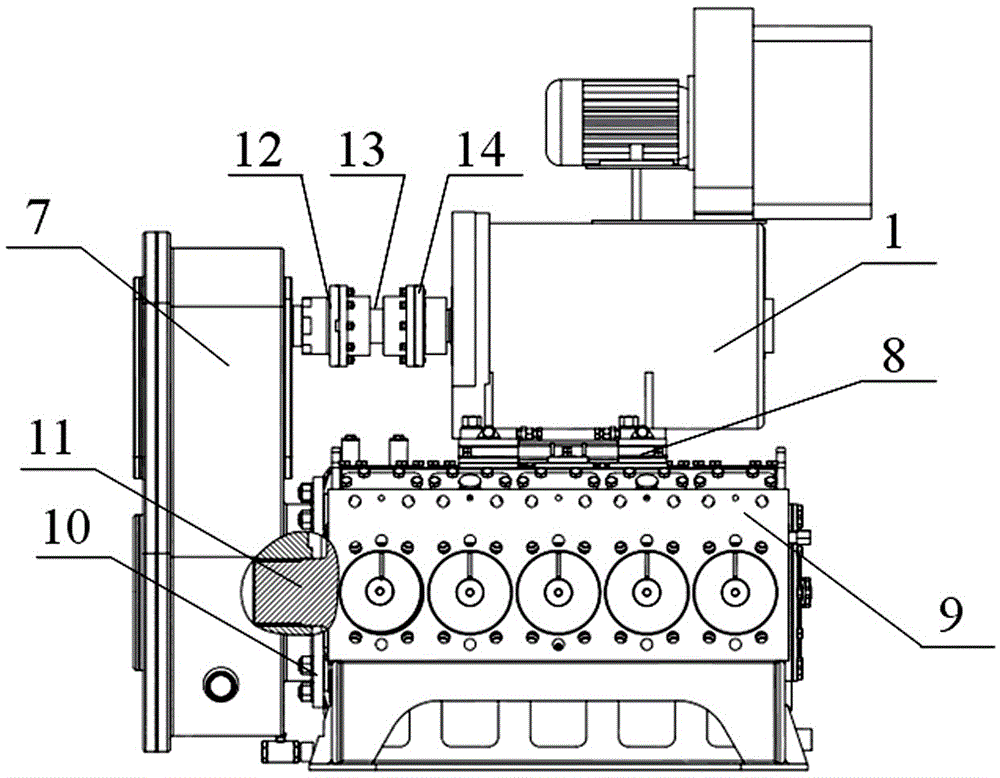

[0023] see Figure 1-4 , a new type of drilling mud pump, a new type of drilling mud pump, the base 5 is sequentially installed with a hydraulic end assembly 6, a power end assembly 3 and a lubrication system 2 from front to back.

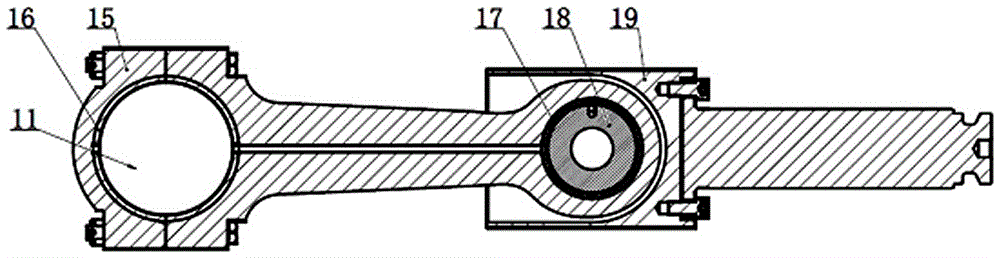

[0024] The power end assembly 3 includes a driving motor 1, a gear reduction box 7, and a crankshaft 11, a connecting rod 15 and a crosshead 19 installed in the pump casing 9; the driving motor 1 is an AC variable frequency motor, which can realize stepless speed regulation, and through The motor installation base 8 is installed on the top of the pump casing 9, and the gear reduction box 7 is installed on one side of the pump casing 9; the output end of the driving motor 1 passes through the motor output flange 14, the spherical cage synchronous coupling 13, and the input of the reduction box in sequence. The flange 12 is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com