Welded corrugated pipe type work doing unit of heat engine

A bellows type, heat engine technology, applied in the direction of hot gas variable capacity engine device, mechanical equipment, machine/engine, etc., can solve the problems of reducing processing difficulty and production cost, reduce processing difficulty and production cost, and eliminate sealing problems. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

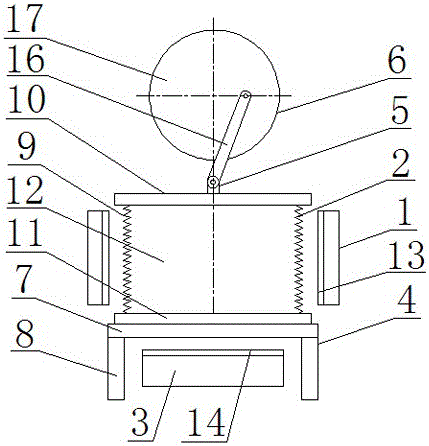

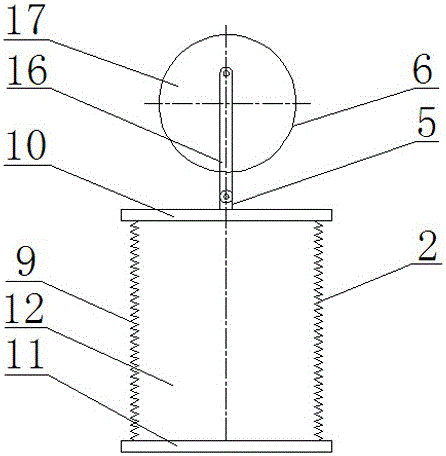

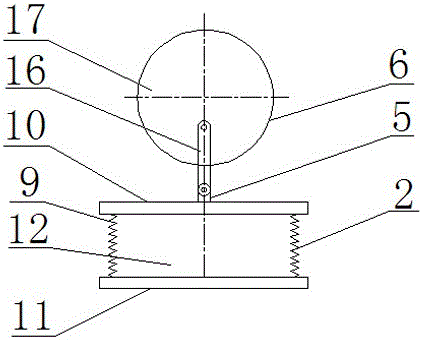

[0020] With reference to the accompanying drawings, a welded bellows type heat engine working unit includes a heater 1, a welded bellows 2, a cooler 3, a frame 4, a hinge support 5 and a transmission mechanism 6; the frame 4 is composed of a square steel plate 7 and a support The legs 8 are welded. The welded bellows 2 is composed of a hollow metal tube 9, a top end plate 10 and a bottom end plate 11. The upper and lower ends of the hollow metal tube 9 are respectively connected to the top end plate 10 and the bottom end plate 11; the bottom end plate 11 is installed on the top of the square steel plate 7, the cooler 3 is installed on the bottom of the square steel plate 7, the heater 1 is installed around the outer tube wall of the hollow metal tube 9, the top end plate 10 is connected to the transmission mechanism 6 through the hinge support 5, and the hollow metal tube 9 A gaseous medium 12 is injected into the lumen of the tube 9 .

[0021] The heater 1 is a cylindrical el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com