Self-adaptive separated layer water injection regulation and control valve

A layered water injection, adjustment and control technology, applied in the direction of wellbore/well valve device, wellbore/well components, production fluid, etc., can solve the problems of water flooding, water channeling and unsatisfactory production wells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Specific embodiments of the present invention will be described in detail below.

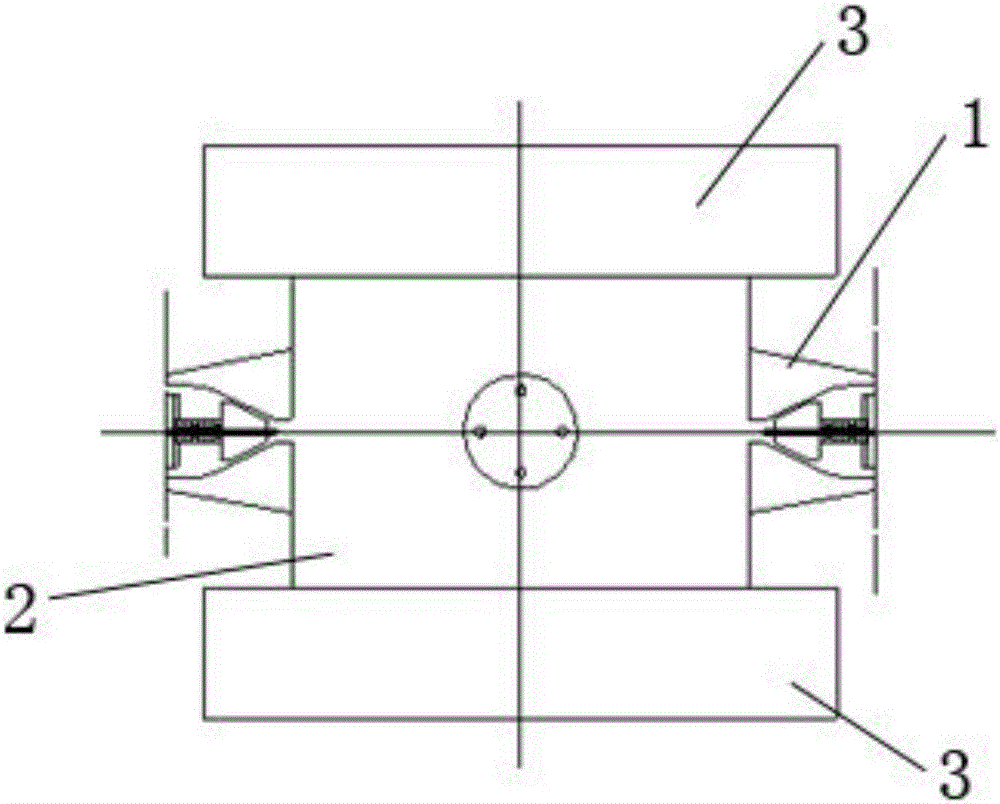

[0030] An adaptive layered water injection regulation control valve, including a water injection valve body 1, an installation short 2 and a mechanical packer 3,

[0031] The outer walls of both ends of the installation short 2 are provided with external threads, and the mechanical packer 3 is respectively connected with the two ends of the installation short 2 through threads,

[0032] The outer wall of the short circuit 2 is symmetrically welded with four water injection valve bodies 1, and the water injection valve body 1 is provided with a hemispherical inner cavity.

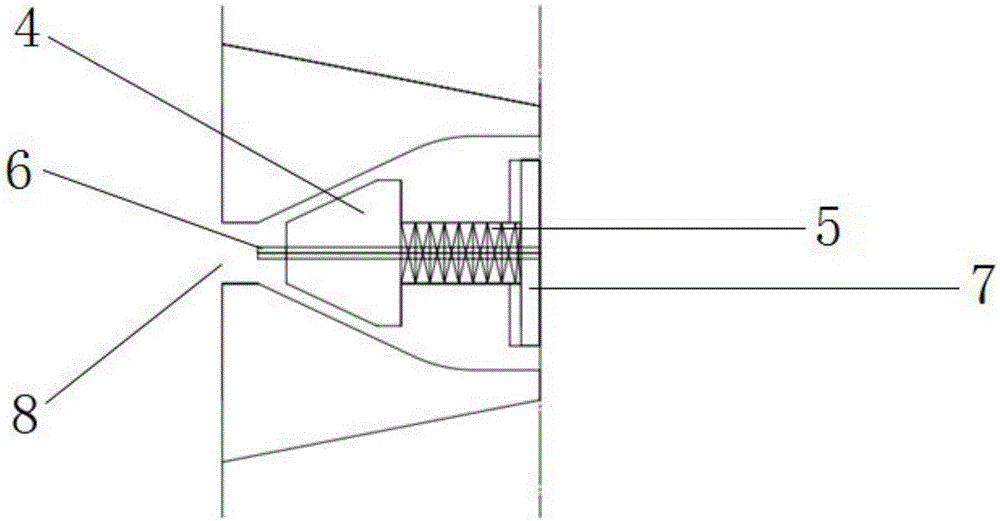

[0033] Water injection valve body 1 comprises piston 4, piston spring 5, piston guide track 6, base 7 and water inlet nozzle 8,

[0034] The outer wall of the installation short circuit 2 is symmetrically provided with four through holes, the position of the through holes corresponds to the position of the water inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com