Drilling device of roadway floor anchor rod

A drilling device and bottom plate technology, applied in the direction of supporting devices, bolt installation, drilling equipment and methods, etc., can solve the problems of large manpower and material resources consumption, inadaptation, complicated operation, etc., and achieve easy operation control and high installation efficiency , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below with reference to the accompanying drawings.

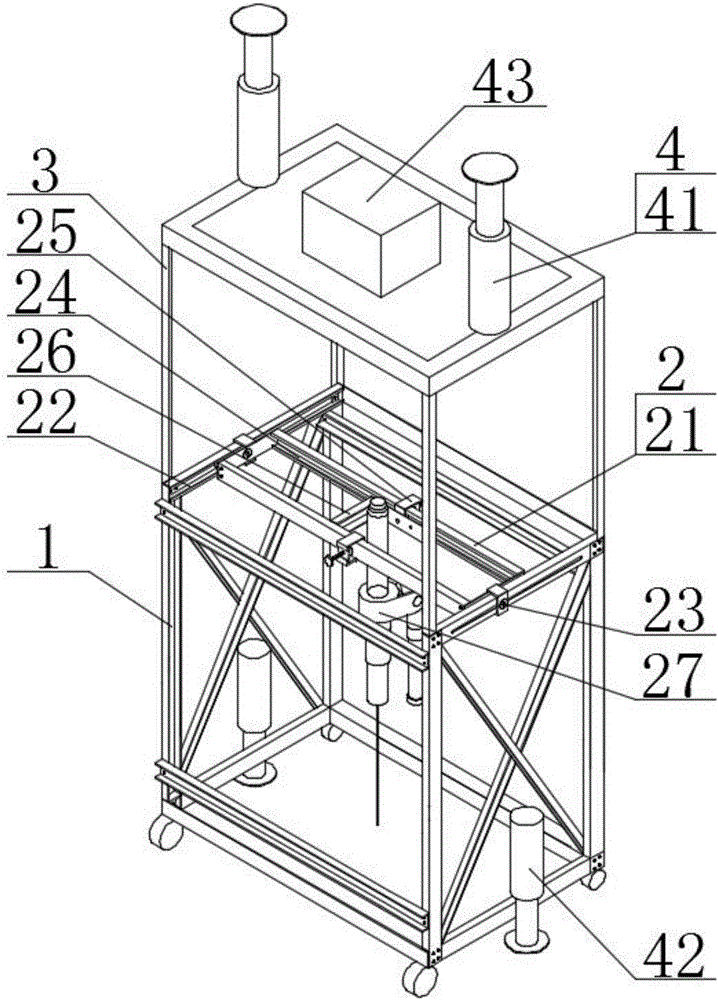

[0018] like figure 1 As shown, this roadway floor bolt drilling device includes a bottom frame 1 , a working part 2 , an upper frame 3 and a device positioning part 4 .

[0019] The upper frame 3 is fixedly installed on the bottom frame 1, and the bottom end of the bottom frame 1 is provided with a roller.

[0020] The working part 2 is installed on the chassis 1, and includes a main body 21, a front and rear guiding mechanism 22, a front and rear positioning mechanism 23, a left and right guiding mechanism 24, a left and right positioning mechanism 25, a drilling rig mounting frame 26 and a drilling rig 27; the body 21 passes through the front and rear directions. The provided front and rear guide mechanisms 22 are erected on the chassis 1; the front and rear positioning mechanisms 23 are cooperatively arranged on the front and rear guide mechanisms 22, and the body 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com