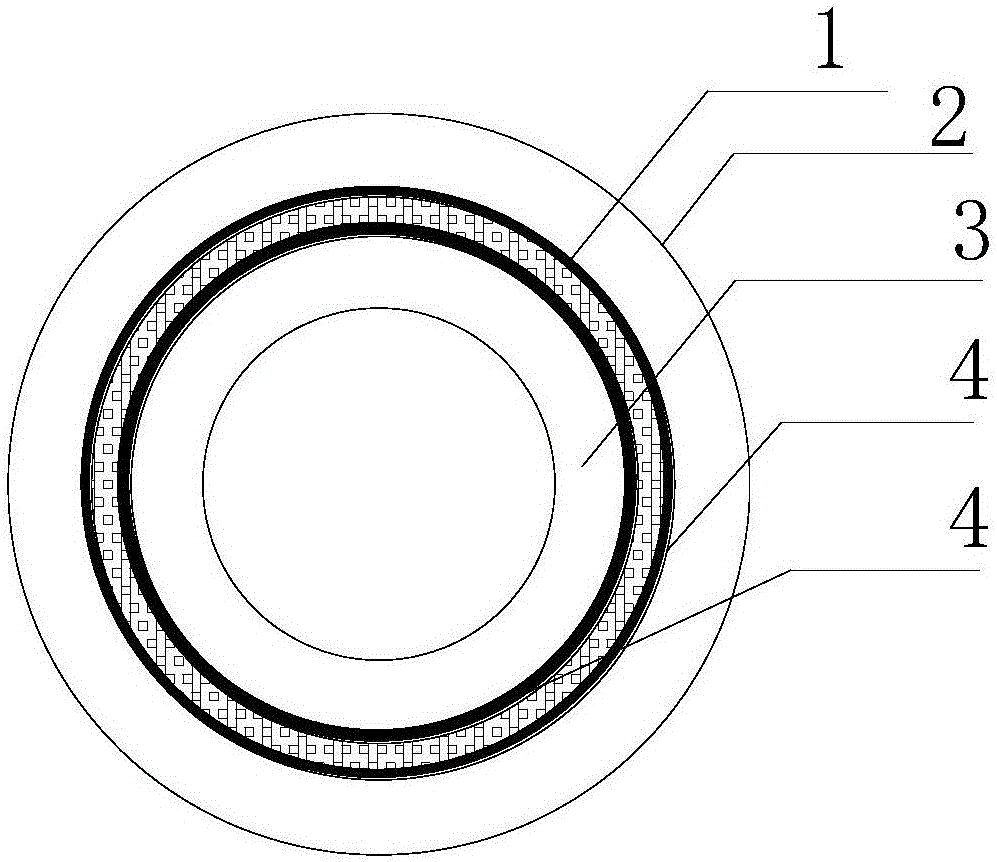

Anti-buckling support with circumferential prestressing, method and application

An anti-buckling support and prestressing technology, applied in the direction of earthquake resistance, building types, buildings, etc., can solve the problems of weakening the core material, reducing the reliability of the support, and prone to buckling, so as to reduce the amount of materials, reduce the weight of components, and The effect of buckling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

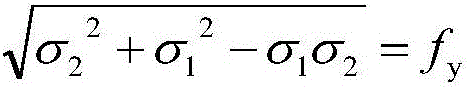

[0042] Embodiment 1: The extrusion stress of the supporting core material steel pipe along the wall thickness direction of the steel pipe is usually less than 1 MPa, so it can be ignored. Only hoop tensile stress and axial stress are considered. Under the bidirectional stress state, according to the Mises yield criterion, the yield condition of the steel is

[0043] σ 2 2 + σ 1 2 - σ 1 σ 2 = f y

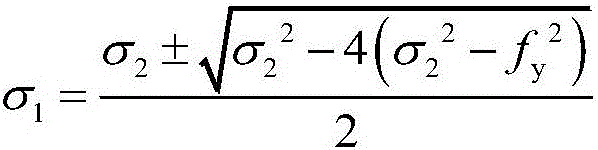

[0044] σ 1 Can be expressed as:

[0045] σ 1 = σ 2 ± ...

Embodiment 2

[0050] Embodiment 2: The cross-section of the anti-buckling support core material steel pipe is Φ300x6, the cross-sectional size of the inner casing is Φ288.5x6, and the cross-sectional size of the outer casing is Φ312x6. The inner diameter of the outer casing is the same as the outer diameter of the core steel pipe, which can be assembled normally. The outer diameter 288.5mm of the inner casing is greater than the inner diameter 288mm of the core steel pipe. Use liquid nitrogen to lower the temperature of the inner casing from room temperature 20°C to 125°C to -105°C, and the shrinkage of the steel pipe is 0.5mm. At this time, the outer diameter of the inner casing is the same as the inner diameter of the core material, and can be assembled. After the assembly is completed, the temperature of the inner casing rises from -105°C to 20°C, and the temperature rises to 125°C. Due to the limitation of the core material steel for temperature rise and expansion, the outer diameter ...

Embodiment 3

[0051] Embodiment 3: The cross-section of the anti-buckling support core material steel pipe is Φ300x6, the cross-sectional size of the inner casing is Φ288.5x6, and the cross-sectional size of the outer casing is Φ312x6. The inner diameter of the outer casing is the same as the outer diameter of the core steel pipe, which can be assembled normally. The outer diameter 288.5mm of the inner casing is greater than the inner diameter 288mm of the core steel pipe. Use an electric furnace to raise the temperature of the core steel pipe from a room temperature of 20°C to 125°C to 145°C, and the expansion of the core steel pipe is 0.5mm. At this time, the outer diameter of the inner casing is the same as the inner diameter of the core material, and can be assembled. After the assembly is completed, the temperature of the core steel pipe drops from 145°C to 20°C, and the temperature drops by 125°C. Since the cooling shrinkage of the core steel pipe is limited by the inner sleeve stee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Compressive yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com