Truss beams, composite beams using truss beams and composite floors using truss beams

A composite floor and truss girder technology, which is applied to the direction of load-bearing elongated structural members, floor slabs, structural elements, etc., can solve problems such as difficulty in realizing industrialized production, uneven bottom surface of floor slabs, and uneven bottom of floor slabs, etc., to achieve Improve dust, light weight, improve the effect of performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

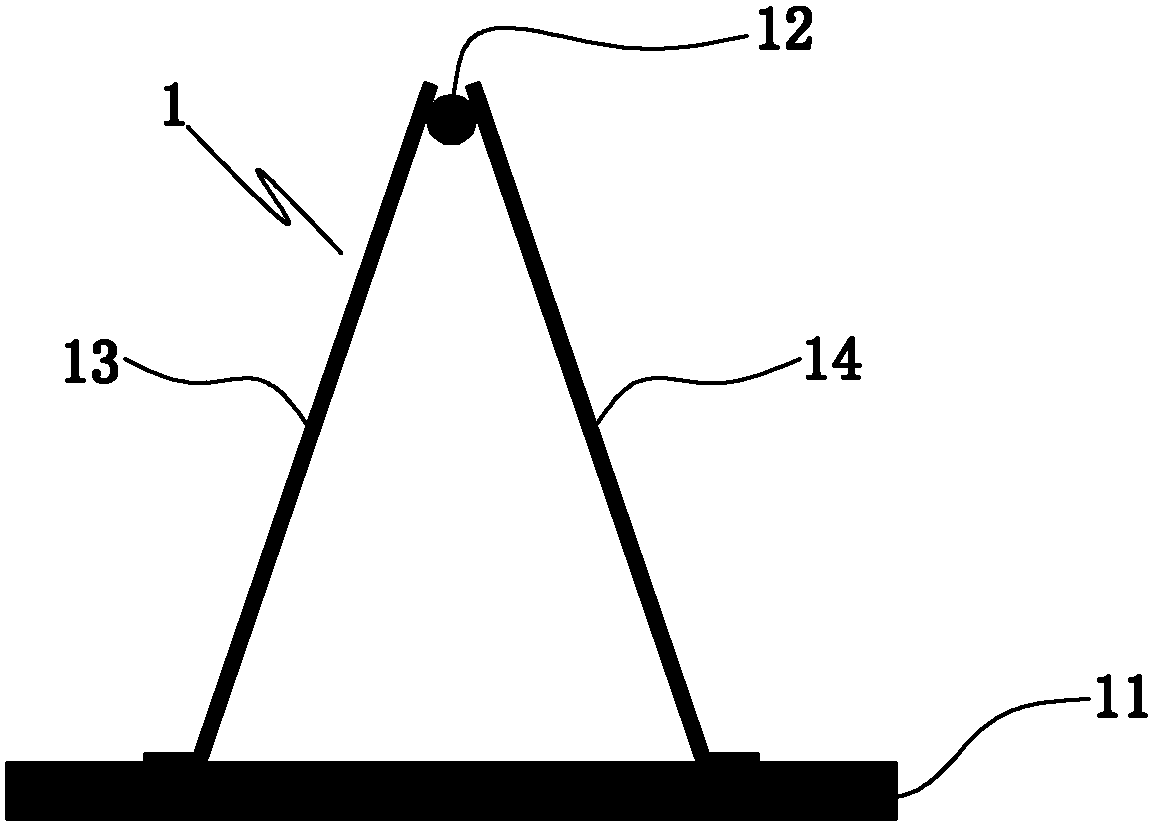

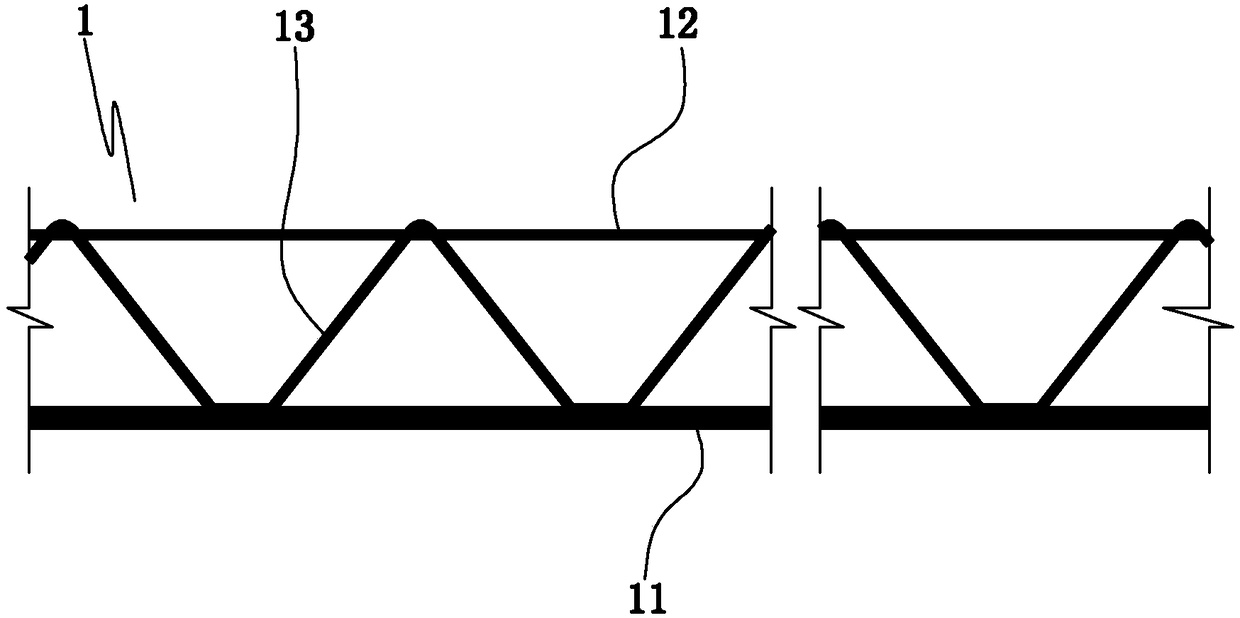

[0033] Embodiment 1: as figure 1 , figure 2 As shown, a truss girder includes a lower chord 11 , an upper chord 12 located above the lower chord, and a connecting web connecting the upper chord and the lower chord. The lower chord plate is parallel to the upper chord member. The lower chord board is steel plate or concrete prefabricated board. The upper chord members are steel bars or steel pipes or H-shaped, I-shaped, and channel-shaped steel members.

[0034] The web bar includes a left web bar 13 and a right web bar 14, and the left web bar and the right web bar are located on opposite sides of the upper chord member. The left abdominal rod and the right abdominal rod are symmetrically distributed on both sides of the upper chord member. The upper chord member, the left web member, the right web member and the lower chord plate form a truss beam with a triangular cross section.

[0035] The left abdominal bar and the right abdominal bar are arranged in waves. The upp...

Embodiment 2

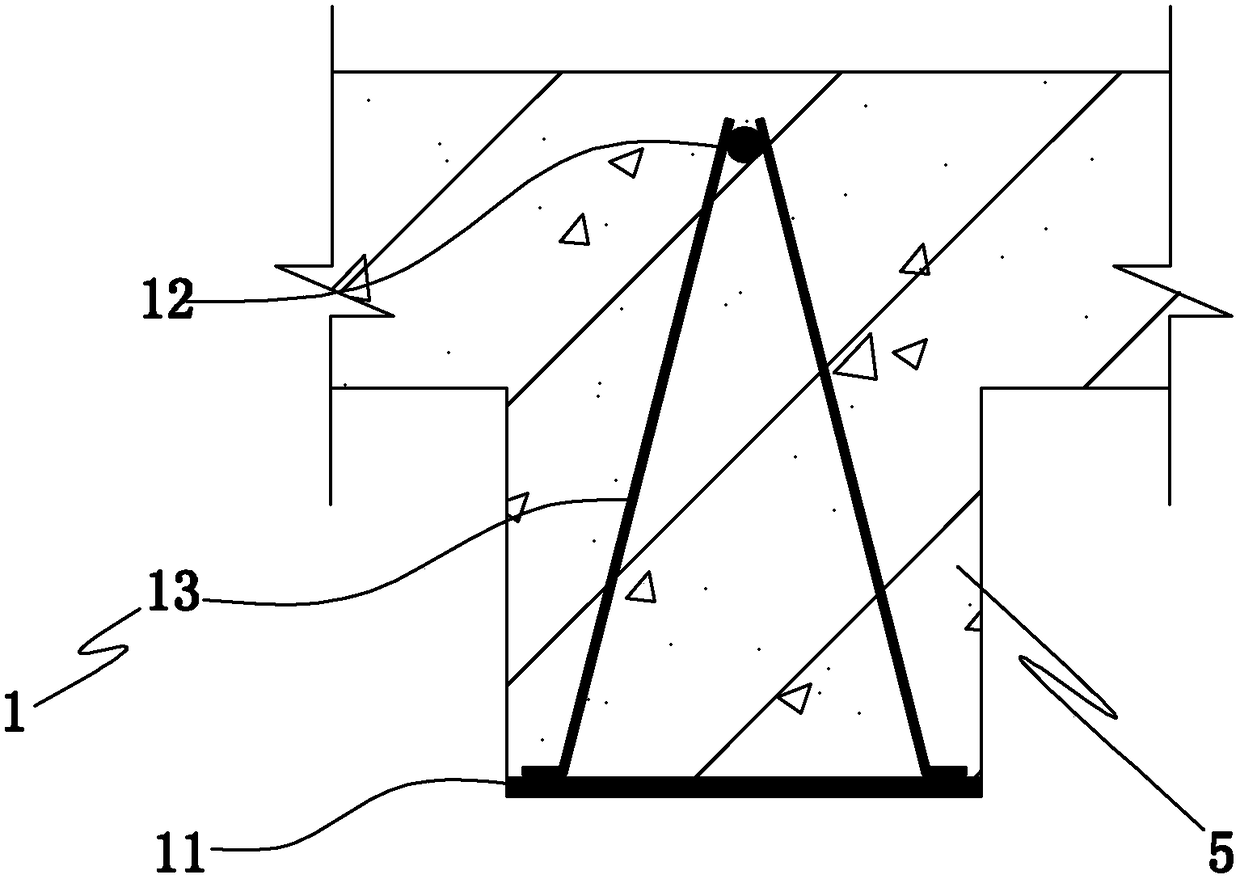

[0037] Embodiment 2: as image 3 As shown, a composite beam is composed of concrete and a truss beam 1 . For the specific structure of the truss girder in this embodiment, refer to Embodiment 1. The lower chord plate of the truss girder is also provided with auxiliary shear connectors. The auxiliary shear connectors are steel bars or studs or anchors or steel pipes or H-beams or I-beams or channel steels. The upper chord member of the truss beam, the connecting web member and the auxiliary shear connector are located inside the composite beam 5 . The lower chord plate of the truss beam is located on the lower surface of the composite beam, and the lower chord plate is connected with the concrete through the connecting web. The upper chord member is used to bear the upper tension of the composite beam, the connecting web is used to bear the shear force of the composite beam, and the lower chord is used to bear the lower tension of the composite beam.

Embodiment 3

[0038] Embodiment 3: as Figure 4 , Figure 5 As shown, a composite floor includes a main frame beam 2 , a truss beam 1 , a number of light plate bottom forms 3 and a concrete floor 4 . For the specific structure of the truss girder in this embodiment, refer to Embodiment 1. The truss beam is supported on the main frame beam through the lower chord plate 11 . The truss beams are located between the lightweight sheet bottom forms. The concrete floor slab is located above the bottom formwork of the lightweight slab, and the concrete floor slab and the truss beams are integrated into a whole. In actual construction: after the concrete floor is poured, the truss beam and concrete are combined to form a steel-concrete composite beam, and the composite beam and the cast-in-place concrete slab are combined to form an integral concrete floor, which is combined with a lightweight plate base form to become Composite floors with integral structure, and work together.

[0039] For any ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com