Detachable settlement joint high-waterproofing structure and construction method thereof

A waterproof structure and settlement joint technology, applied in building structure, construction and other directions, can solve the problems of poor waterproof effect, short service life, difficult maintenance, etc., and achieve the effect of good waterproof effect, not easy to damage and failure, and low maintenance cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

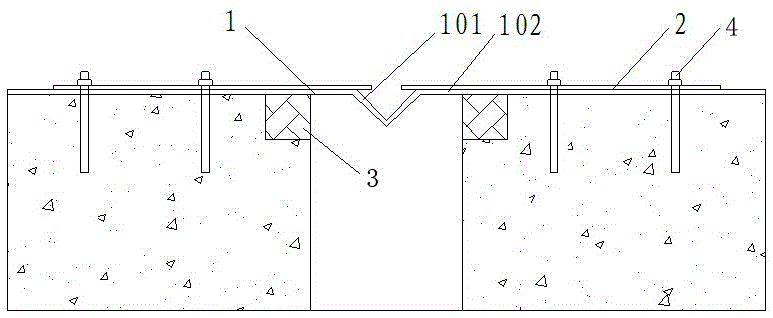

[0022] A detachable high waterproof structure for settlement joints. There are clamping platforms on the top of the concrete wall on both sides of the settlement joints. The clamping platforms are embedded with water-expandable water-stop strips 3, which are installed above the water-expandable water-stop strips 3. There is a rubber water-stop plate 1 covering the settlement joint. The rubber water-stop plate 1 includes a groove part 101 arranged in the cavity of the settlement joint and having a V-shaped cross-section and two respectively connected to the two side walls of the groove part 101. The fixed part 102 is provided with a steel plate 2 above the two fixed parts 102, and there is a gap above the settlement joint between the two steel plates 2, and the steel plate 2 and the fixed part 102 are fixed on the concrete wall by the expansion bolt 4 superior.

[0023] The width of the gap between the two steel plates 2 is 10mm.

[0024] The groove portion 101 is formed by fi...

Embodiment 2

[0033] A detachable high waterproof structure for settlement joints. There are clamping platforms on the top of the concrete wall on both sides of the settlement joints. The clamping platforms are embedded with water-expandable water-stop strips 3, which are installed above the water-expandable water-stop strips 3. There is a rubber water-stop plate 1 covering the settlement joint. The rubber water-stop plate 1 includes a groove part 101 arranged in the cavity of the settlement joint and having a V-shaped cross-section and two respectively connected to the two side walls of the groove part 101. The fixed part 102 is provided with a steel plate 2 above the two fixed parts 102, and there is a gap above the settlement joint between the two steel plates 2, and the steel plate 2 and the fixed part 102 are fixed on the concrete wall by the expansion bolt 4 superior.

[0034] The width of the gap between the two steel plates 2 is 12 mm.

[0035] The groove portion 101 is formed by f...

Embodiment 3

[0044] A detachable high waterproof structure for settlement joints. There are clamping platforms on the top of the concrete wall on both sides of the settlement joints. The clamping platforms are embedded with water-expandable water-stop strips 3, which are installed above the water-expandable water-stop strips 3. There is a rubber water-stop plate 1 covering the settlement joint. The rubber water-stop plate 1 includes a groove part 101 arranged in the cavity of the settlement joint and having a V-shaped cross-section and two respectively connected to the two side walls of the groove part 101. The fixed part 102 is provided with a steel plate 2 above the two fixed parts 102, and there is a gap above the settlement joint between the two steel plates 2, and the steel plate 2 and the fixed part 102 are fixed on the concrete wall by the expansion bolt 4 superior.

[0045] The width of the gap between the two steel plates 2 is 15 mm.

[0046] The groove portion 101 is formed by f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Gap width | aaaaa | aaaaa |

| Gap width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com