Small-sized soaking etching machine for laboratory

A technology for laboratory etching machines, applied in the field of laboratory small immersion etching machines, can solve the problems of inability to realize automatic transportation, inability to realize automation, and low processing efficiency, so as to realize automatic transportation and prevent corrosion of operators , small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

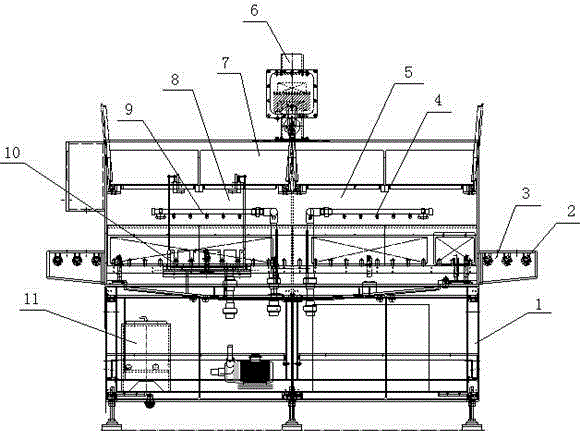

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings.

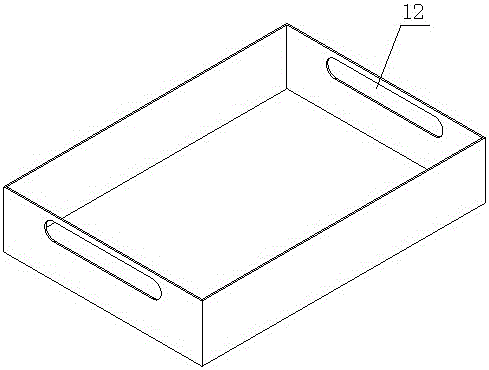

[0014] like figure 1 and figure 2 A small immersion etching machine for a laboratory is shown, comprising a frame body 1, on which a conveying table 3 is arranged, and on the described conveying table 3, several conveying rollers 2 are arranged, and the The frame body 1 is divided into a spray soaking part 8 and a water washing spray part 5, a soaking pool 10 is arranged at the conveying roller 2 of the spray soaking part 8, and at both ends of the soaking pool 10 Each is provided with a slot 12 for the workpiece to enter, and a baffle plate capable of lifting and sealing the slot 12 is provided outside the slot 12; a corrosive liquid spray pipe 9 is provided above the spray soaking part 8; A water washing and spraying pipeline 4 is provided above the washing and spraying part 5; a corrosive liquid heating tank 11 is provided at the bottom of the frame body 1, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com