Microemulsion-type washing liquid system for oil-based drilling fluid and preparation method thereof

An oil-based drilling fluid and microemulsion technology, applied in the field of oil and gas well cementing, can solve the problems of poor interface cementation quality and low flushing efficiency, and achieve the effects of preventing emulsion blockage, improving flushing efficiency, and high solubilization ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

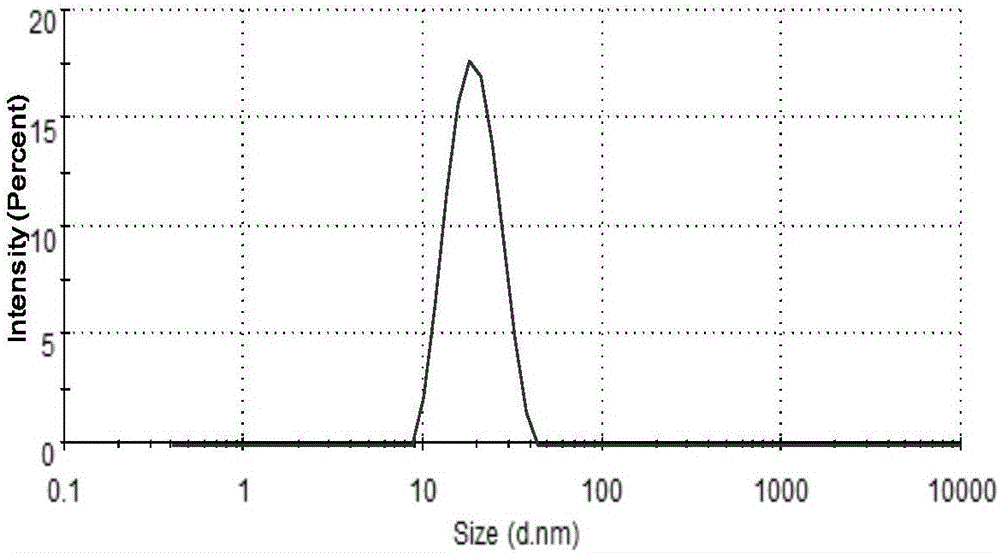

[0024] Embodiment 1: A kind of composition of microemulsion flushing fluid system suitable for oil-based drilling fluid

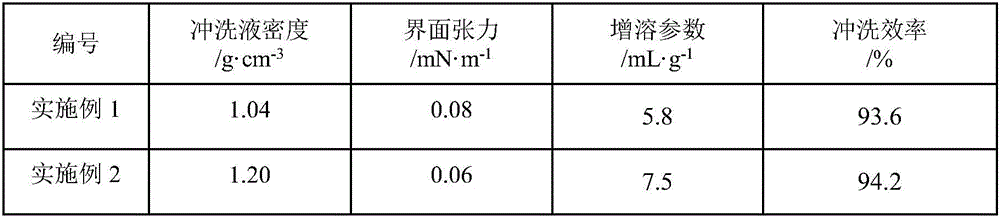

[0025] A microemulsion flushing fluid system suitable for oil-based drilling fluid consists of microemulsion flushing agent and base fluid. The microemulsion flushing agent can be composed of the following substances, and the mass parts of each substance are specifically: 100 parts of clear water, 4 parts of anionic surfactant bis(2-ethylhexyl) sulfosuccinate, 4 parts of nonionic surfactant iso 3 parts of tridecyl alcohol polyoxyethylene ether, 6 parts of co-surfactant n-butanol, and 7 parts of sodium chloride. The mass concentration of xanthan gum in the base liquid is 0.1%, the weighting agent barite mass concentration is 3%, and the flushing agent is added according to 15% of the mass fraction of the base liquid to prepare a microemulsion flushing liquid. Measure the interfacial tension between flushing fluid and oil with a spinning drop interfacial ten...

Embodiment 2

[0026] Embodiment 2: A kind of composition of microemulsion flushing fluid system suitable for oil-based drilling fluid

[0027] A microemulsion flushing fluid system suitable for oil-based drilling fluid consists of microemulsion flushing agent and base fluid. The microemulsion flushing agent can be composed of the following substances, and the mass parts of each substance are specifically: 100 parts of clear water, 6 parts of anionic surfactant bis(2-ethylhexyl) sulfosuccinate, 6 parts of nonionic surfactant iso 5 parts of tridecanol polyoxyethylene ether, 9 parts of co-surfactant n-butanol, and 10 parts of sodium chloride. The mass concentration of xanthan gum in the base liquid is 0.5%, the weighting agent quartz sand mass concentration is 25%, the washing liquid is added according to the mass fraction of 10% of the base liquid, the interfacial tension between the washing liquid and oil is measured, and its solubilization parameters for oil are calculated , Determination ...

Embodiment 3

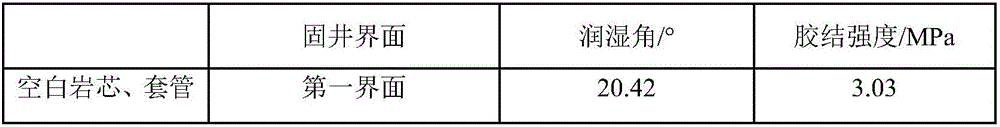

[0031] Example 3: Evaluation of the wetting and inversion performance of the flushing solution system on the cemented surface

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com