A three-layer vesicular polyaniline/graphene composite material and a preparing method thereof

A composite material, polyaniline technology, applied in the field of three-layer vesicular polyaniline/graphene composite material and its preparation, can solve problems such as toxic environmental hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] (1) Preparation of vesicular SiO with 6-7 layers 2 Measure 35mL of distilled water into a 100mL beaker, then add 0.1420gCTAB to the beaker, stir until clear, then add 0.1126g DDAB, stir at 30°C for 24h to obtain a mixed dispersion; transfer the mixed dispersion to a polytetrafluoroethylene liner In the high-pressure reactor, tighten the high-pressure reactor and put it in an oven, react at 100°C for 24 hours, cool the high-pressure reactor to room temperature after hydrothermal treatment, and obtain a precipitate; the obtained precipitate is separated by suction filtration and dried , calcined at 550 °C for 6 h after grinding to obtain 6-7 layers of vesicular SiO 2 .

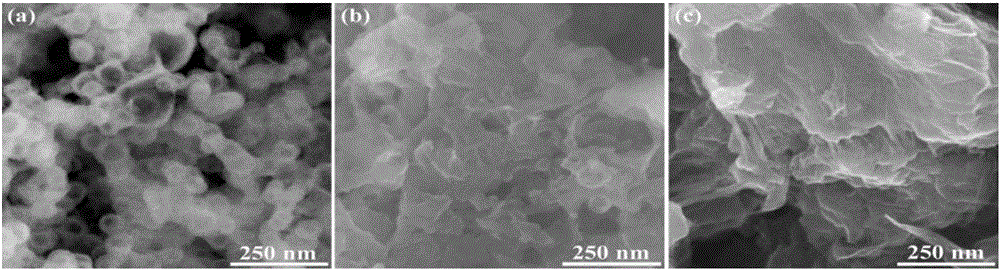

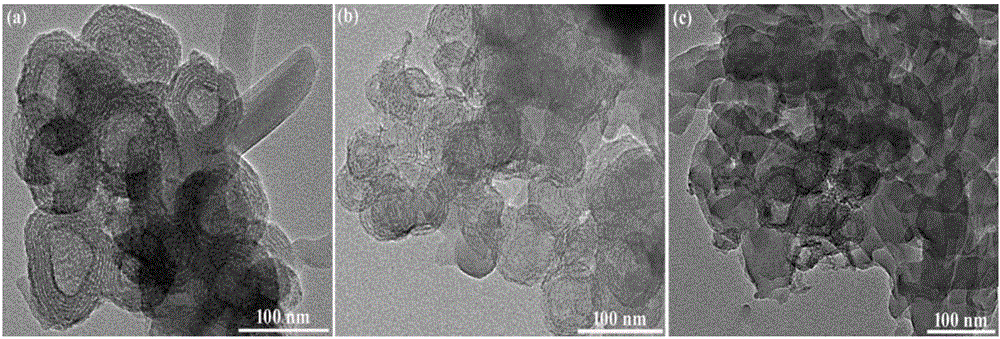

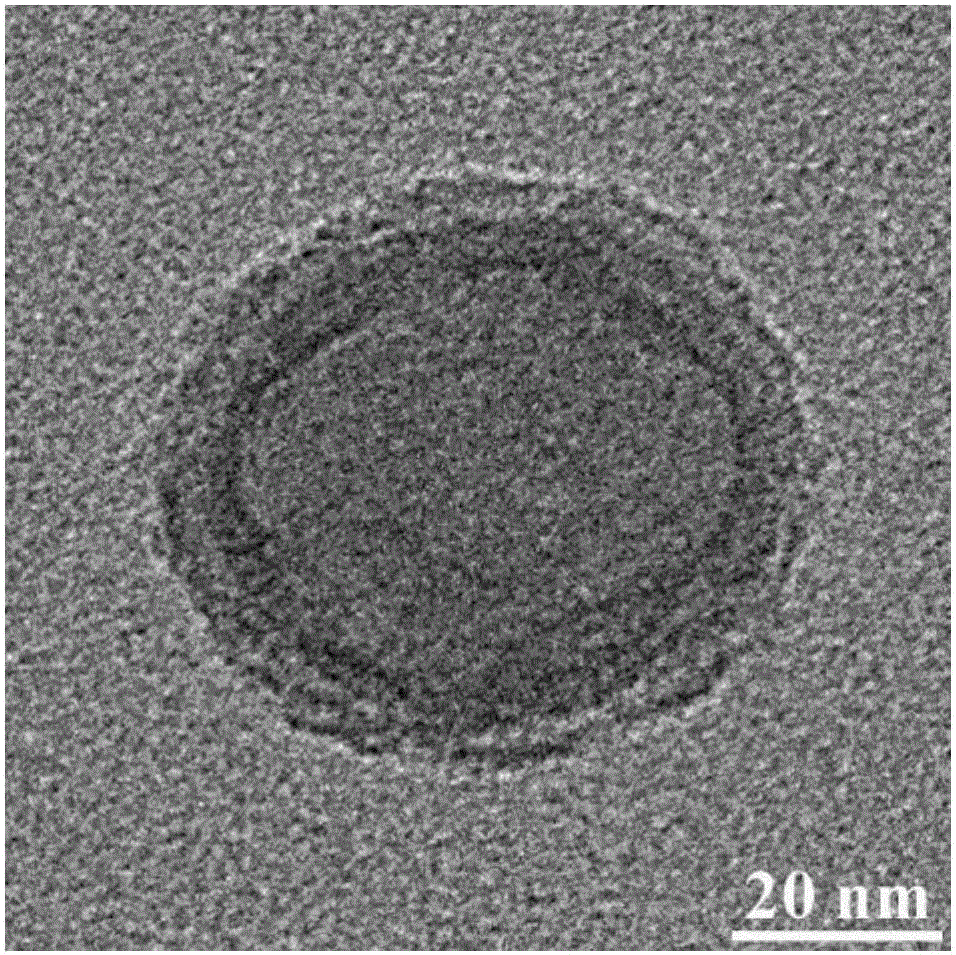

[0076] (2) Preparation of vesicular SiO with 6-7 layers 2 / polyaniline composites such as figure 1 a Add 30mL 1mol L -1 HCl solution, 0.0100g vesicular SiO with 6-7 layers 2 , 0.0500g SDS were added in the beaker successively, ultrasonic 30min to dissolve completely, obtain mixed dispersion liquid;...

Embodiment 2

[0080] (1) Preparation of 3-4 layers of vesicular SiO 2 Measure 35mL of distilled water into a 100mL beaker, then add 0.1420g CTAB to the beaker, stir until clear, then add 0.1500g DDAB, stir at 30°C for 24h to obtain a mixed dispersion; transfer the mixed dispersion to a polytetrafluoroethylene liner In the high-pressure reactor, tighten the high-pressure reactor and put it in the oven, react at 100°C for 24 hours, cool the high-pressure reactor to room temperature after hydrothermal treatment, and obtain a precipitate; after the obtained precipitate is separated by suction filtration, After drying, calcining at 550°C for 6h after grinding to obtain 3-4 layers of vesicular SiO 2 .

[0081] (2) Preparation of 3-4 layers of vesicular SiO 2 / polyaniline composite material with 30mL 1mol L -1 HCl solution, 0.0100g 3-4 layers of vesicular SiO 2, 0.0500g SDS were added to the beaker in turn, ultrasonic 30min until completely dissolved to obtain a mixed dispersion; the mixed d...

Embodiment 3

[0085] (1) Preparation of vesicular SiO with 2-3 layers 2 Measure 35mL of distilled water into a 100mL beaker, then add 0.1420g CTAB to the beaker, stir until clear, then add 0.2000g DDAB, stir at 30°C for 24h to obtain a mixed dispersion; transfer the mixed dispersion to a polytetrafluoroethylene liner In a high-pressure reactor, tighten the high-pressure reactor and put it in an oven, react at 100°C for 24 hours, cool the high-pressure reactor to room temperature after hydrothermal treatment, and obtain a precipitate; after the obtained precipitate is separated by suction filtration, After drying, calcining at 550°C for 6h after grinding to obtain 2-3 layers of vesicular SiO 2 .

[0086] (2) Preparation of vesicular SiO with 2-3 layers 2 / polyaniline composite material with 30mL 1mol L -1 HCl solution, 0.0100g vesicular SiO with 2-3 layers 2 , 0.0500g SDS were added to the beaker in turn, ultrasonic 30min until completely dissolved to obtain a mixed dispersion; the mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com