Superhard heat-shrinkable bush material, superhard heat-shrinkable bush and preparation method of superhard heat-shrinkable bush

A technology of heat-shrinkable sleeves and pipes, which is applied to tubular objects, other household appliances, applications, etc., can solve the problems of low hardness of heat-shrinkable sleeves, minimize internal structure damage, be easy to operate, and improve product safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1 A kind of superhard heat-shrinkable sleeve and its preparation method

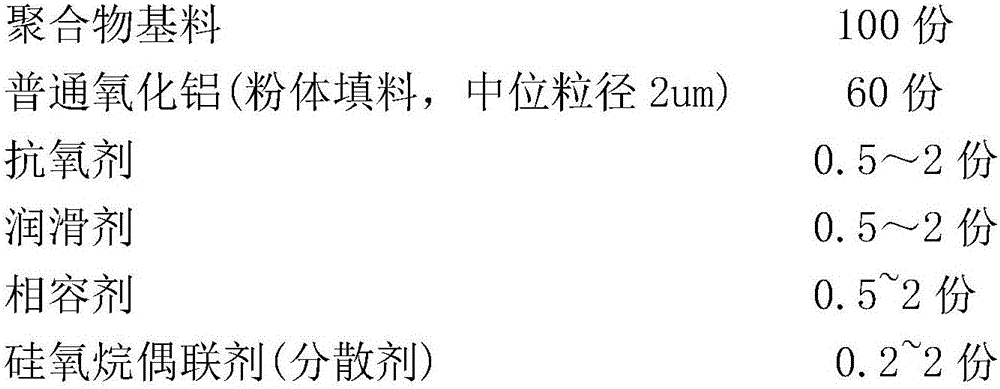

[0033] A kind of superhard heat-shrinkable sleeve of this embodiment is prepared from heat-shrinkable sleeve material, and the formula of heat-shrinkable sleeve material is as follows:

[0034]

[0035] The superhard heat-shrinkable sleeve of this embodiment is prepared by the following steps:

[0036] Step S1: Add 100 parts of ordinary silicon oxide with a median particle size of 3um into the stirring equipment, start the equipment at a speed of 200 rpm, and add dropwise a dispersant with a mass content of 10% diluted by an organic solvent, wherein the dispersant is silicon oxide The alkane coupling agent, the organic solvent is ethanol, and the dropwise addition is completed in 3 minutes. Adjust the equipment speed to 1000 rpm, disperse for 10 minutes, and control the temperature of the filler at 50-80 ° C. Stop the machine and let it stand to cool down to room temperature.

[003...

Embodiment 2

[0042] Embodiment 2 A kind of superhard heat-shrinkable sleeve and its preparation method

[0043] A kind of superhard heat-shrinkable sleeve of this embodiment is prepared from heat-shrinkable sleeve material, and the formula of heat-shrinkable sleeve material is as follows:

[0044]

[0045] The superhard heat-shrinkable sleeve of this embodiment is prepared by the following steps:

[0046] Step S1: Add 100 parts of ordinary alumina with a median particle size of 2um into the stirring equipment, start the equipment at a speed of 200 rpm, and add dropwise a dispersant with a mass content of 10% diluted by an organic solvent, wherein the dispersant is silicon oxide The alkane coupling agent, the organic solvent is ethanol, and the dropwise addition is completed in 3 minutes. Adjust the equipment speed to 1000 rpm, disperse for 10 minutes, and control the temperature of the filler at 50-80 ° C. Stop the machine and let it stand to cool down to room temperature.

[0047] Ste...

Embodiment 3

[0052] Embodiment 3 A kind of superhard heat-shrinkable sleeve and its preparation method

[0053] A kind of superhard heat-shrinkable sleeve of this embodiment is prepared from heat-shrinkable sleeve material, and the formula of heat-shrinkable sleeve material is as follows:

[0054]

[0055] The superhard heat-shrinkable sleeve of this embodiment is prepared by the following steps:

[0056] Step S1: Add 100 parts of ordinary alumina with a median particle size of 2um into the stirring equipment, start the equipment at a speed of 200 rpm, and add dropwise a dispersant with a mass content of 10% diluted by an organic solvent, wherein the dispersant is silicon oxide The alkane coupling agent, the organic solvent is ethanol, and the dropwise addition is completed in 3 minutes. Adjust the equipment speed to 1000 rpm, disperse for 10 minutes, and control the temperature of the filler at 50-80 ° C. Stop the machine and let it stand to cool down to room temperature.

[0057] Ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com