A kind of melamine polymer material and its application and preparation method in the treatment of heavy metals

A polymer material, melamine technology, applied in chemical instruments and methods, water/sewage treatment, adsorbed water/sewage treatment, etc., can solve the problem of unsatisfactory removal effect of gaseous chlorinated heavy metals, low purification effect of element heavy metals, and high cost, etc. problem, to achieve the effect of low cost, increased specific surface area, and increased coordination points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

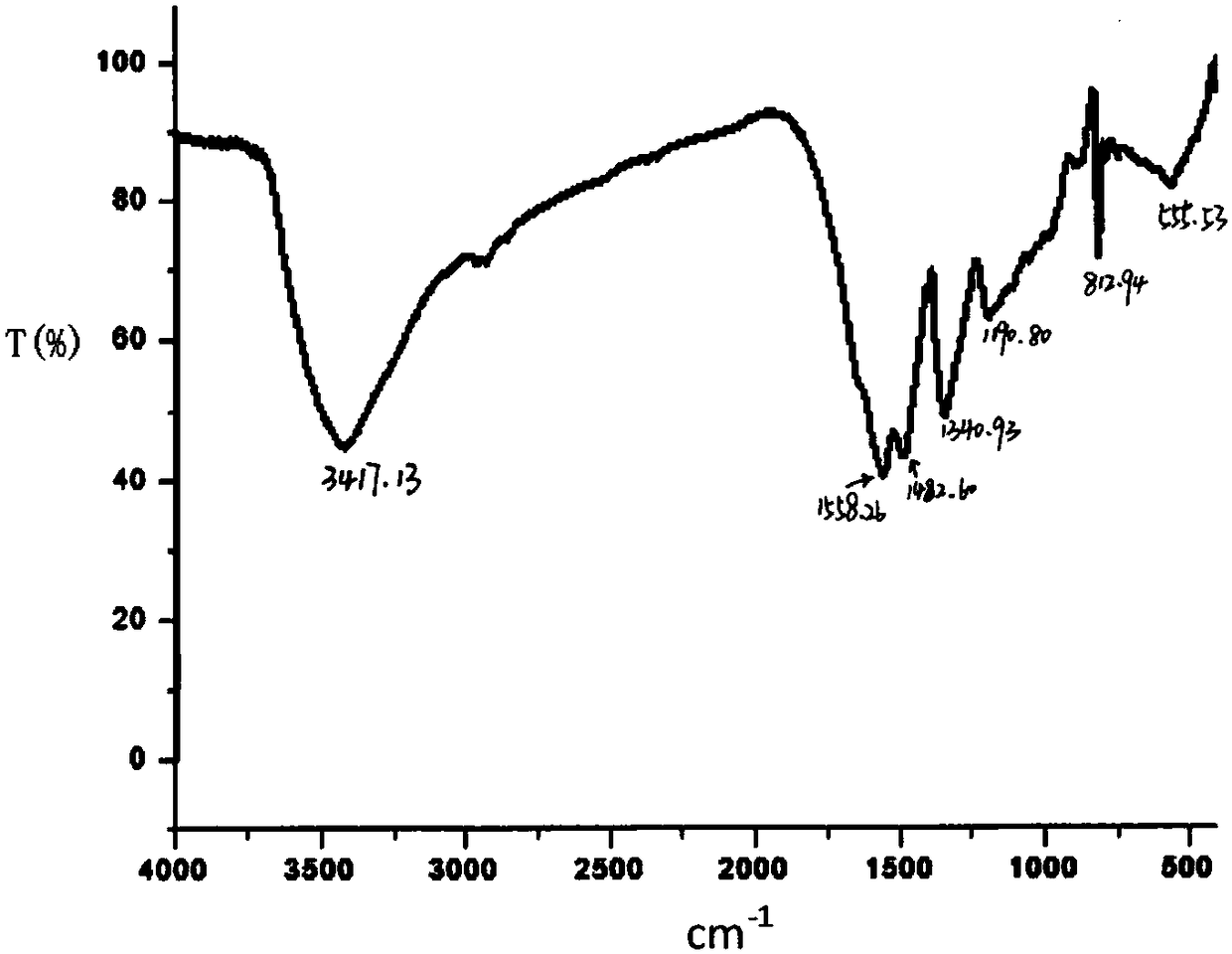

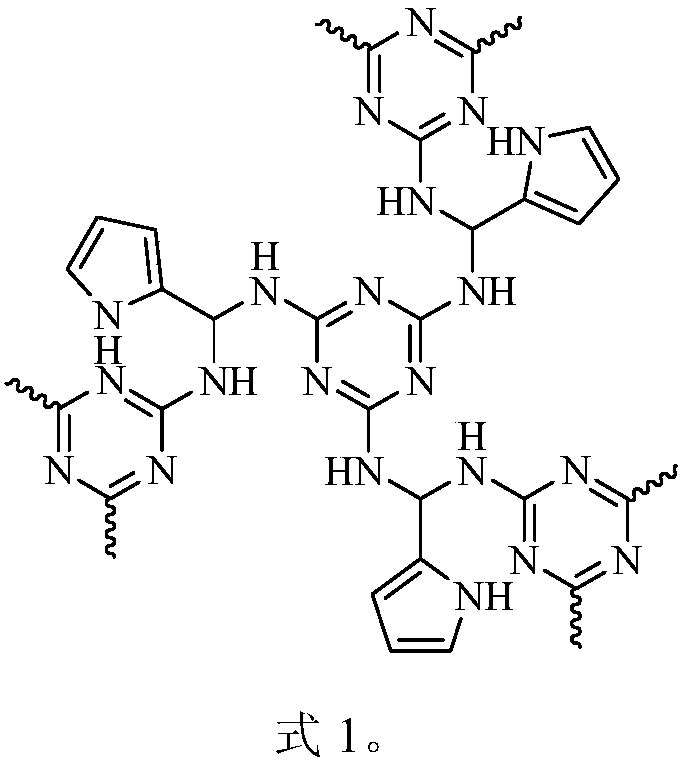

[0033] The polymer material is a polymer obtained by polymerizing melamine and pyrrole formaldehyde in dimethyl sulfoxide (DMSO). The specific synthesis steps are as follows: add 100 g of melamine and 100 g of pyrrole formaldehyde to a 500-milliliter round low flask, then add 250 ml of a dimethyl sulfoxide solution, and the mixture is heated and stirred at 130 degrees Celsius under a nitrogen atmosphere for 15 hours. After cooling, the pale yellow solid was filtered out, washed with water and ethanol, and dried to obtain 189 g of a polymer cross-linked polymer.

Embodiment 2

[0035] The polymer material is a polymer obtained by polymerizing melamine and pyrrole formaldehyde in dimethylformamide (DMF). The specific synthesis steps are as follows: 100 g of melamine and 113.1 g of pyrrole formaldehyde are added to a 500-milliliter round low flask, and then 300 ml of dimethylformamide solution is added, and the mixture is heated and stirred at 110 degrees Celsius under nitrogen for 12 hours. After cooling, the pale yellow solid was filtered out, washed with water and ethanol, and dried to obtain 191 g of a polymer cross-linked polymer.

Embodiment 3

[0037] The polymer material is a polymer obtained by polymerizing melamine and pyrrole formaldehyde in dimethylacetamide (DMAC). The specific synthesis steps are as follows: add 100 g of melamine and 120 g of pyrrole formaldehyde to a 500-milliliter round low flask, and then add 250 ml of dimethylacetamide solution, and the mixture is heated and stirred at 150 degrees Celsius for 8 hours. After cooling, the white solid was filtered out, washed with water and ethanol, and dried to obtain 190 g of a polymer cross-linked polymer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com