Gripping device of stacker

A technology of grabbing device and palletizer, which is applied in the direction of conveyors, manipulators, and object stacking, which can solve the problems of large space occupied by claws, decoupling, interference of claws, etc., and achieve the effect of saving space and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

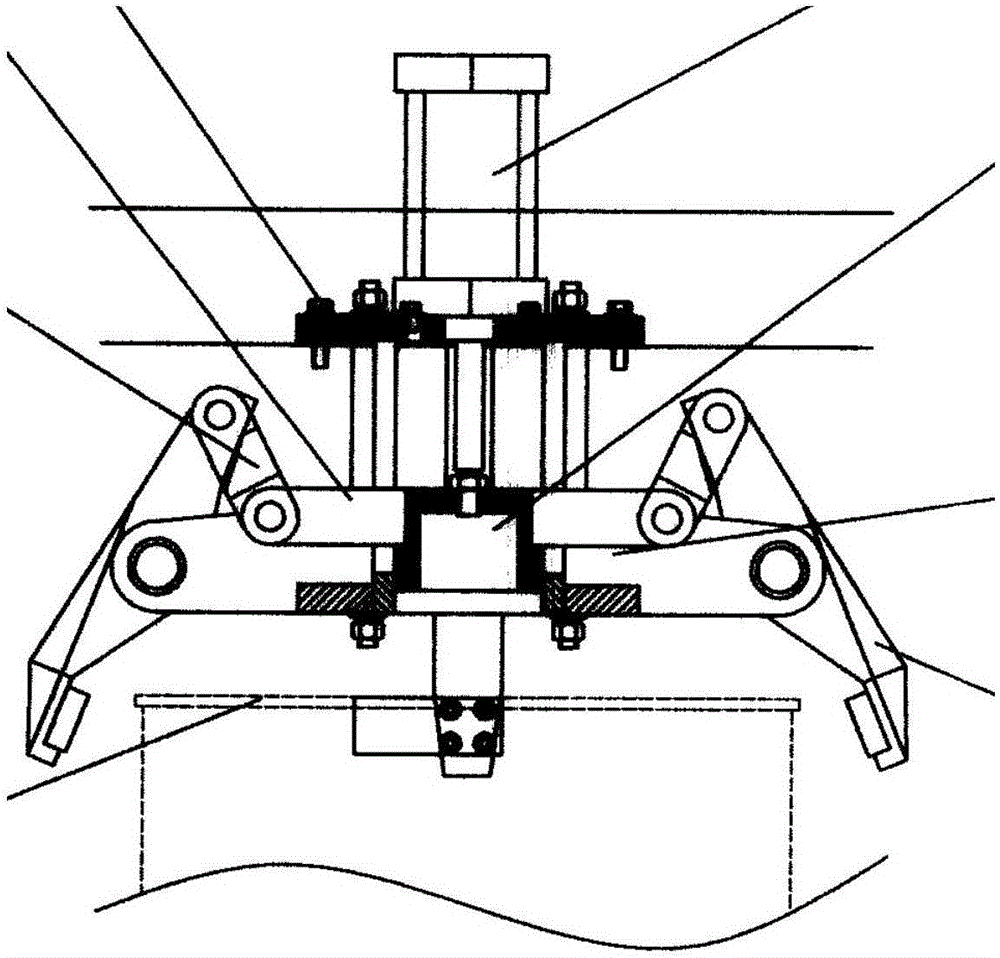

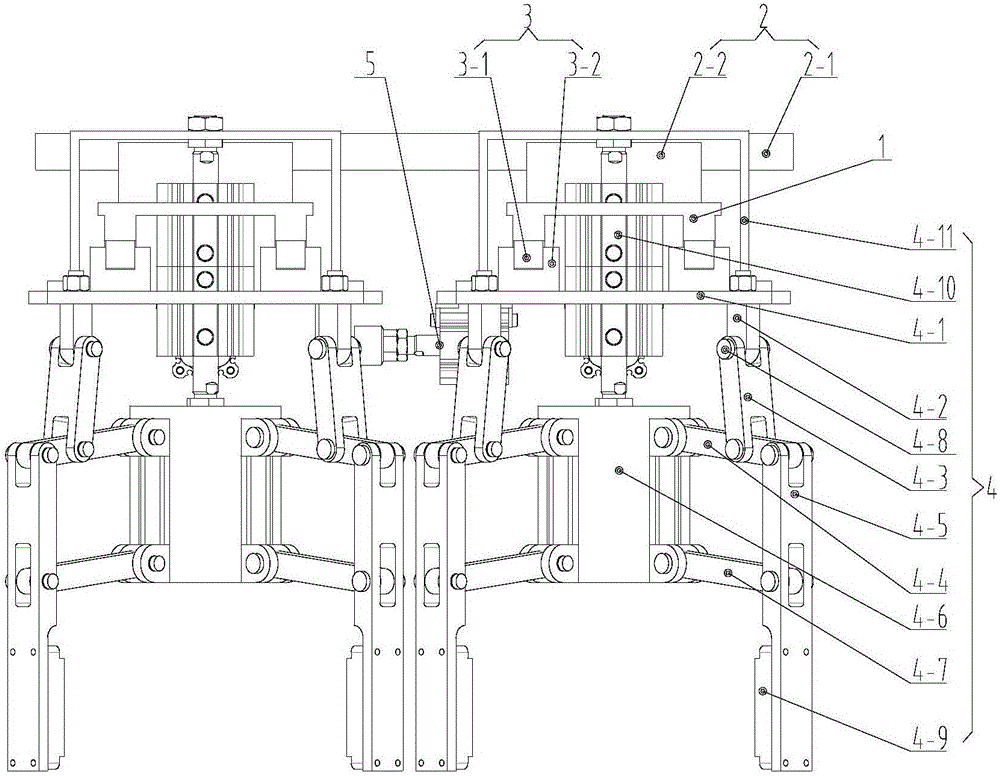

[0034] like image 3 , Figure 4 and Figure 5 As shown, before grabbing the cylinder barrel 6 whose diameter is X, the two cylinder rods of the grab cylinder 4-10 are all stretched out, and the claw body 4-5 goes deep into a certain position vertically along the periphery of the cylinder barrel 6, and the distance adjustment cylinder 5 The cylinder rods are all stretched out, so that the spacing of the grasping group 4 is consistent with the spacing of the cylinder barrel 6; as Image 6 As shown, when grabbing, grabbing one of the cylinder rods of the cylinder 4-10 retracts (the drawing shows that the upper end cylinder rod retracts), and the sleeve frame 4-6 rises under the drive of grabbing the cylinder 4-10, by The parallelogram formed by the three-hole connecting rod 4-4, the claw body 4-5, the sleeve frame 4-6, and the two-hole connecting rod 4-7 is deformed, so that the claw body 4-5 moves to the middle and touches the cylindrical barrel 6 At the same time, the airba...

Embodiment 2

[0036] like image 3 , Figure 7 and Figure 8 As shown, before grabbing the cylindrical barrel 7 with a diameter of Y (Y Figure 9 As shown, when grabbing, the two cylinder rods of the grabbing cylinder 4-10 are all retracted, and the sleeve frame 4-6 rises under the driving of the grabbing cylinder 4-10, and the three-hole connecting rod 4-4, claw The parallelogram formed by the body 4-5, the sleeve frame 4-6, and the two-hole connecting rod 4-7 is deformed, so that the claw body 4-5 moves to the middle and touches the edge of the cylinder barrel 7; meanwhile, the air bag 4-9 Inflate and clamp the cylindrical barrel 7, thereby completing a grab and getting ready for the stacking of the cylindrical barrel 7. After the palletizing was completed, the two cylinder rods of the grabbing cylinder 4-10 stretched out, the sleeve frame 4-6 descended, and the claw body 4-5 moved to the outside, while the air bag was deflated, and the grabbing device reset.

[0037] Illustrate a point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com