Oil-drive transverse type four-rotor agricultural plant protection unmanned helicopter

An unmanned helicopter, quadrotor technology, applied in the direction of rotorcraft, unmanned aircraft, motor vehicles, etc., can solve the problems of waste, poor pesticide spraying effect, etc., to eliminate the impact, wide center of gravity, improve the spraying effect and The effect of pesticide utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

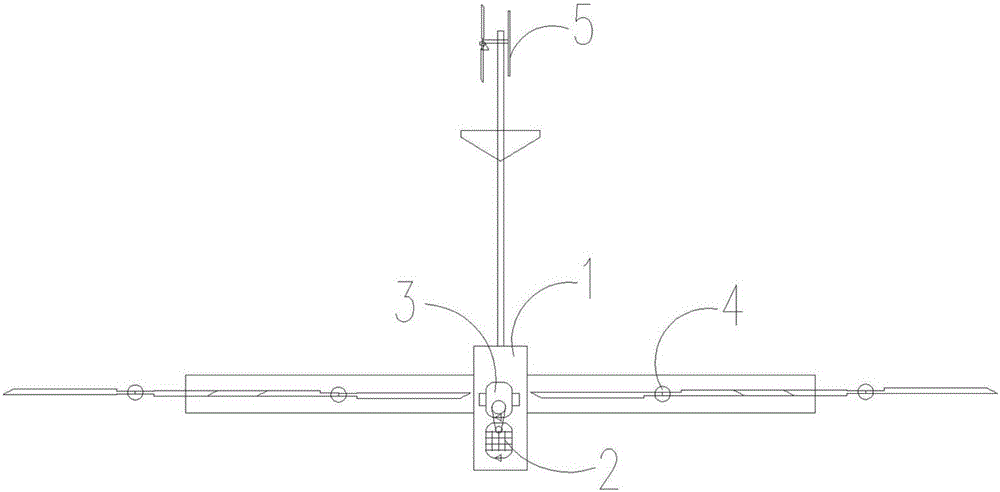

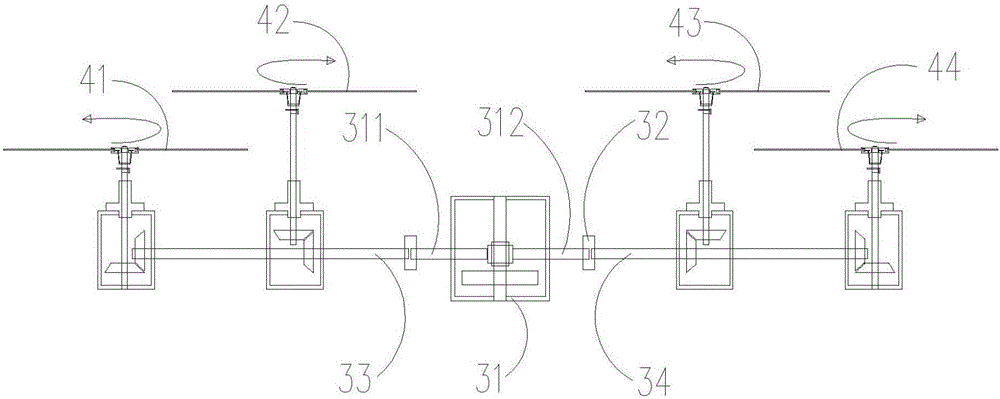

[0027] As shown in the accompanying drawings, the left output shaft 311 and the right output shaft 312 respectively extend symmetrically through the gearbox 31 in the center of the fuselage 1 of the present invention's oil-driven horizontal four-rotor agricultural plant protection unmanned helicopter. The left transmission main shaft 33 and the right transmission main shaft 34 are fixedly connected, and are fixed on the side plate brackets on both sides through the pipe frame; There are steering helical gearboxes, which are respectively matched with the rotor transmission mechanisms at their respective positions to complete the horizontal arrangement of the transmission mechanism. Four rotor shafts with equal speeds and opposite directions are realized through the steering gearbox; the four rotor shafts from left to right No. 1 rotor device 41, No. 2 rotor device 42, No. 3 rotor device 43 and No. 4 rotor device 44 are respectively installed on the shaft. Since the directions of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com