Fire-resistant fabric with distinct layers and high color fastness

A fabric with high color fastness and bright technology, applied in the field of textile fabrics, can solve problems such as single function and lack of three-dimensional effect, achieve strong three-dimensional effect, clear layers, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

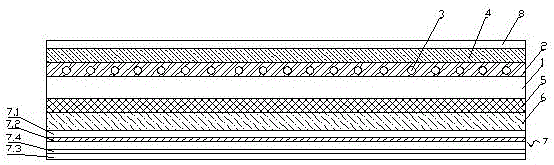

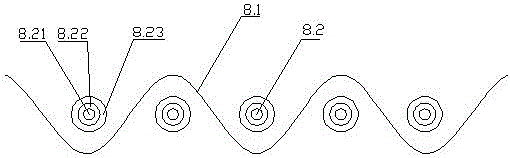

[0023] see Figure 1~3 , the present invention relates to a flame-retardant fabric with distinct layers and high color fastness. Radiation strip 3, the upper surface of the radiation protection layer 2 is provided with an antistatic layer 4, the upper surface of the antistatic layer 4 is provided with a high color fastness layer 8, and the lower surface of the fabric body 1 is provided with an antibacterial layer 5, The antibacterial layer 5 is woven from silver-plated fibers, the lower surface of the antibacterial layer 5 is provided with a fireproof layer 6 , and the lower surface of the fireproof layer 6 is provided with a waterproof layer 7 .

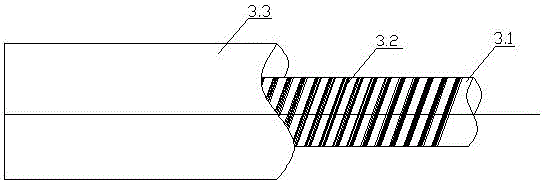

[0024] The anti-radiation strip 3 includes elastic fibers 3.1 in the center, anti-radiation wire groups 3.2 wound on the surface of the elastic fibers 3.1, and a protective layer 3.3 wrapped on the outer layer. There are multiple groups of anti-radiation metal wires wound on the elastic fibers 3.1 Group 3.2, the radiation-proof met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com