Bamboo-tube slicing device

A technology of bamboo tubes and blades, which is applied in the direction of wood splitting devices, wood processing equipment, manufacturing tools, etc., can solve the problems of bamboo tubes and knives being easily damaged, uneven width of bamboo prongs, and large labor workload of workers, so as to achieve uniform width and wide adaptability Sexuality and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

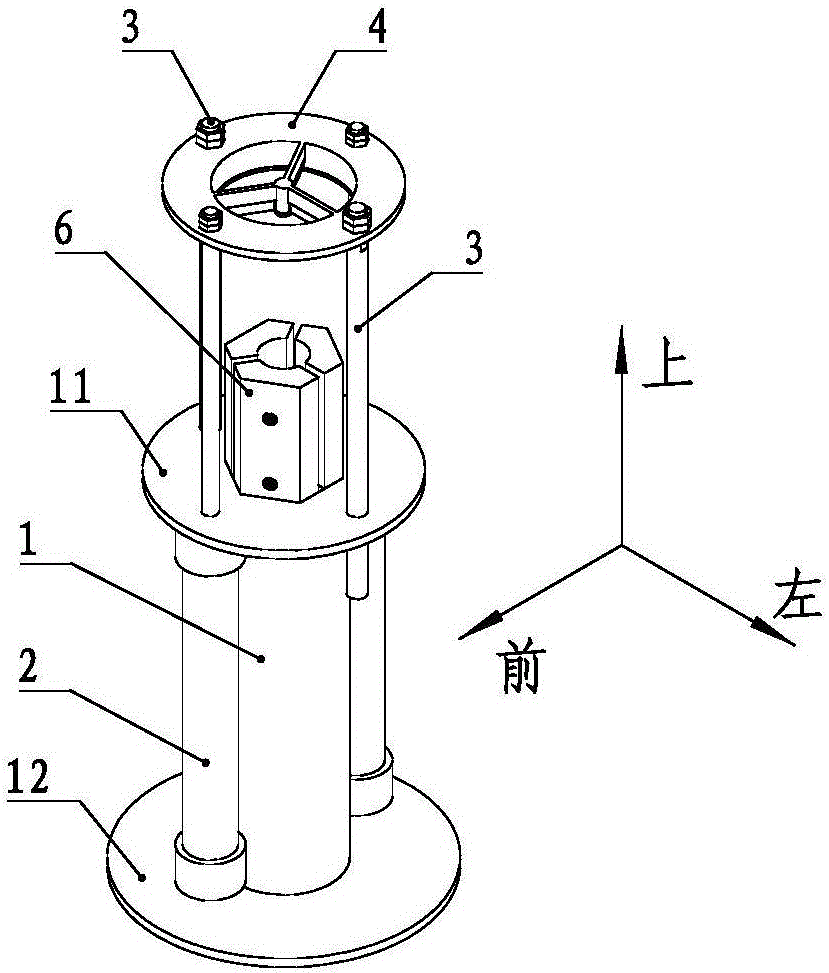

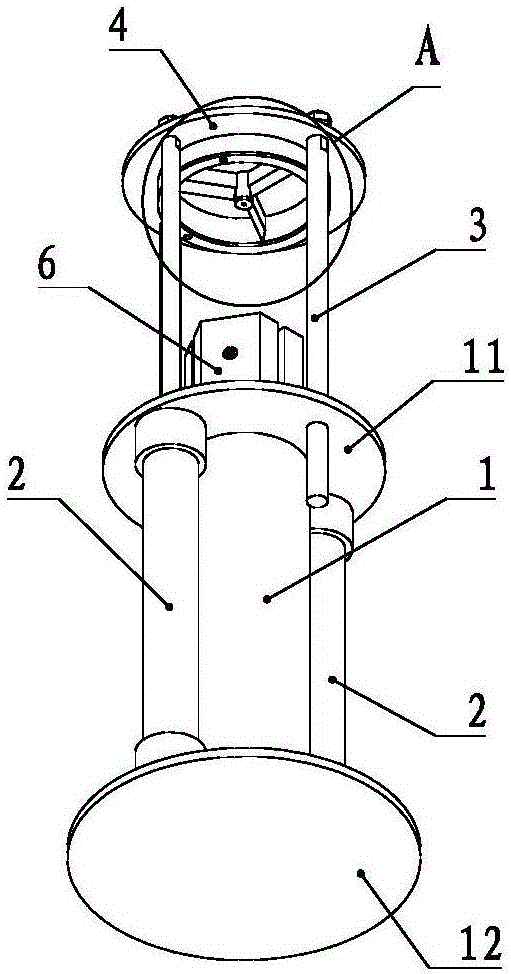

[0032] For the convenience of description, the coordinate system is defined as figure 1 shown.

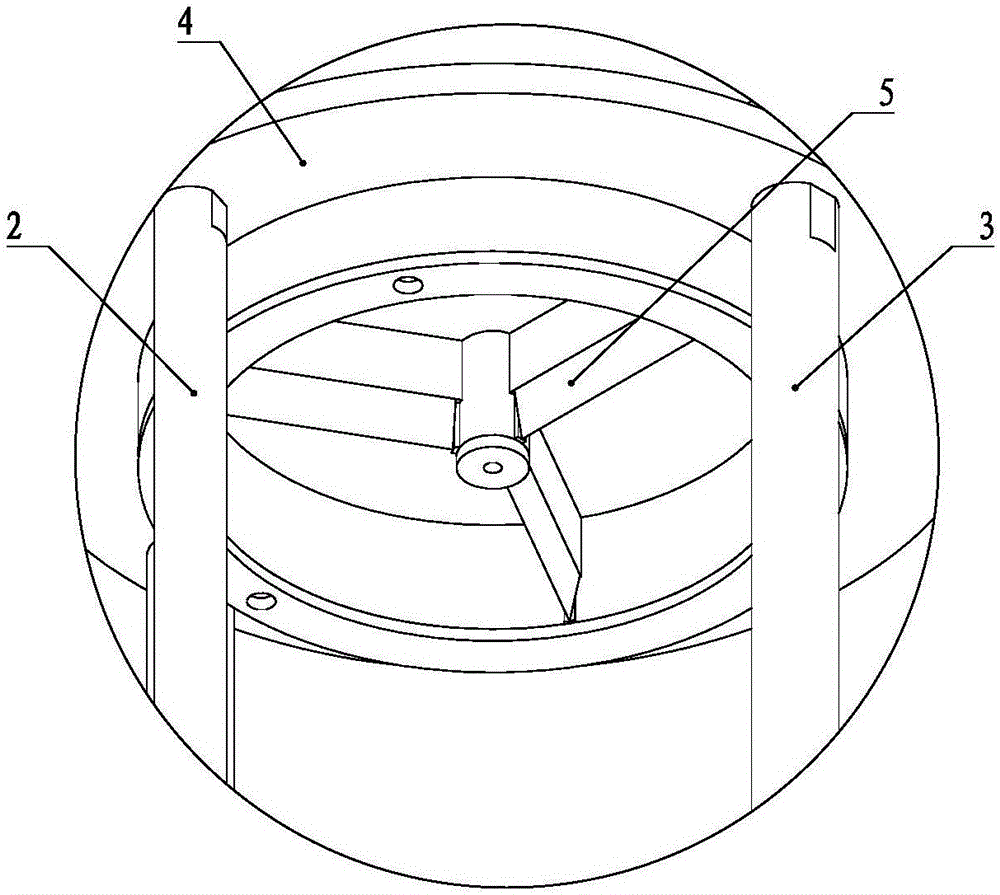

[0033] Such as figure 1 and figure 2 As shown, a bamboo tube slicing device includes a cylindrical base 1, a knife rest 4, a blade 5 and a positioning mechanism 6, and the upper and lower ends of the base 1 are respectively provided with an upper circular plate 11 and a lower circular plate 12. . Between the upper circular plate 11 and the lower circular plate 12, a cylinder 2 is respectively arranged on the front and rear sides of the base 1, the cylinder body of the cylinder 2 is fixedly connected with the upper circular plate 11, and the cylinder 2 is fixedly connected with the said knife rest 4 after passing through the upper circular plate 11. The left and right sides of the base 1 are respectively provided with guide posts 3 between the knife rest 4 and the base 1, the upper ends of the guide posts 3 are fixedly connected with the knife rest 4, and the guide posts The l...

Embodiment 2

[0038] Between the outer ring 41 and the central cylinder 42, four ribs 43 are arranged radially and evenly, and each of the ribs 43 is provided with a first groove 431 along the axial direction. Blade 5 is arranged inside. The corresponding positioning structure includes a positioning block 61 with a regular octagonal cross section, and the third groove is a regular octagonal shape. The side of the positioning block 61 is provided with four second grooves 62 along the axial direction and communicating with each other, and the four second grooves 62 correspond to the four ribs 43 one by one. All the other structures are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com