Device for high-frequency induction brazing machine

A high-frequency induction brazing and basic block technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of inability to guarantee the quality of aircraft parts, inaccurate positioning of aircraft parts, and threats to the lives of operators, and achieve savings. The effect of clamping time, shortening welding time and ensuring welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

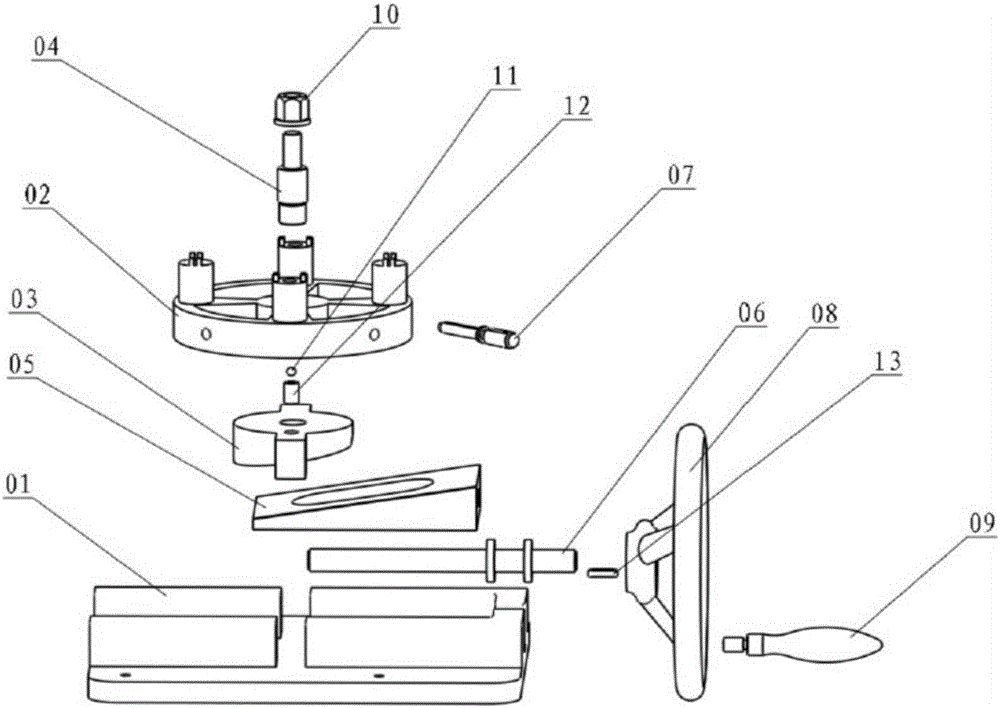

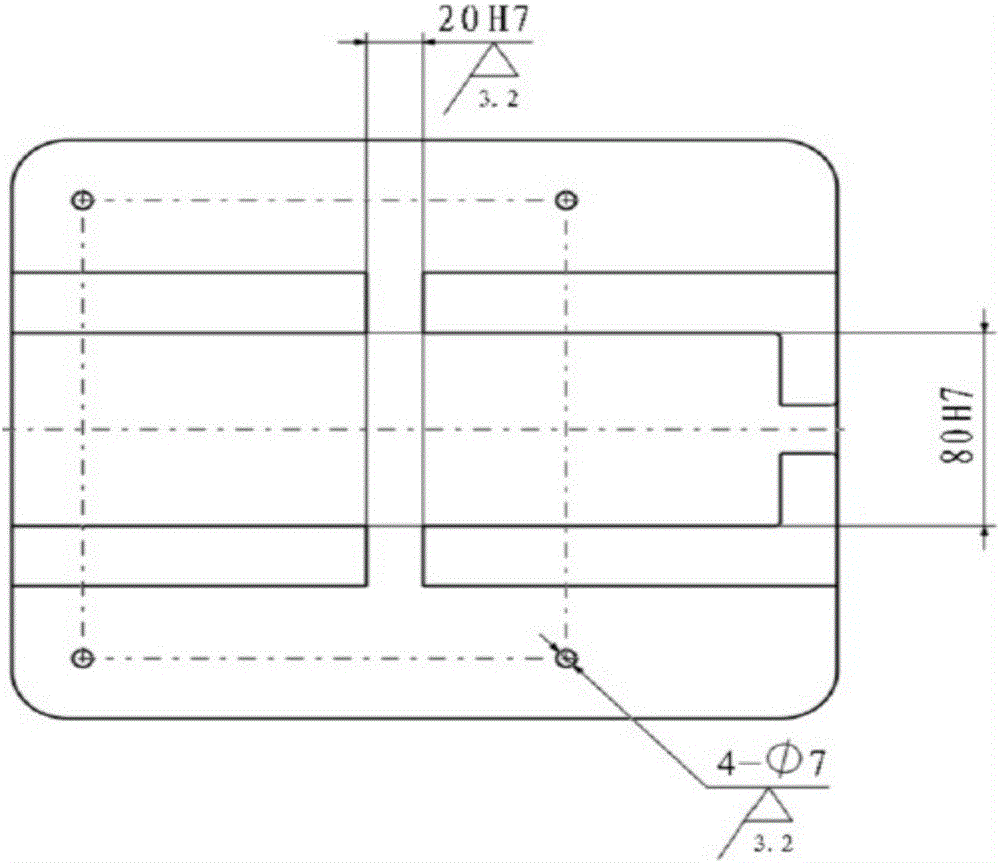

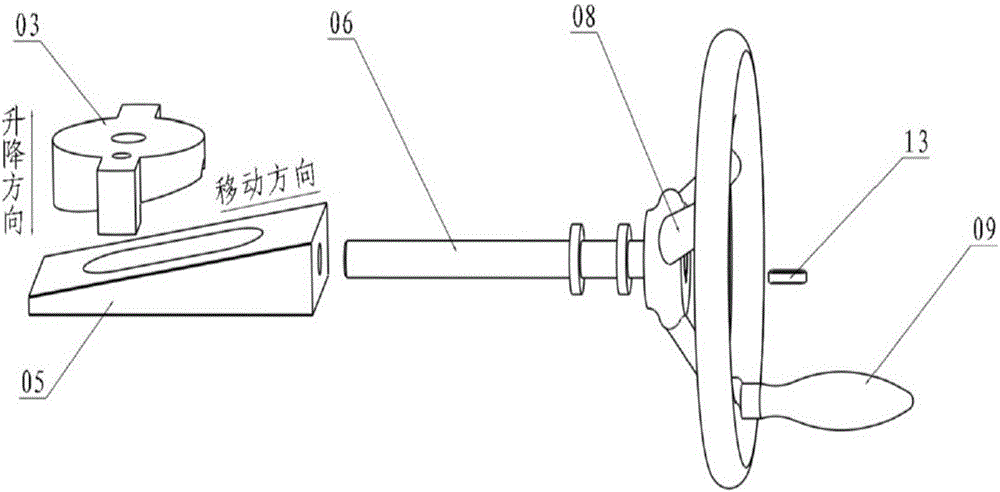

[0036]The U-shaped groove of 80H7 on the basic block 01 is used as the chute of the wedge-shaped block 05. The U-shaped groove can limit the movement of the wedge-shaped block 05 along the length direction of the upper surface of the basic block 01. The chute of the block 03, the elongated through groove can limit the lifting movement of the slider 03 along the height direction of the cuboid of the basic block 01;

Embodiment 2

[0038] After the round wheel handle 08, the curved surface handle 09, the ordinary flat key 13, the screw 06, and the wedge block 05 are connected, by rotating the curved surface handle 09, the round wheel handle 08 is driven to rotate, and the screw 06 is rotated together, and the wedge block 05 is on the screw 06 Driven by the drive, it can reciprocate on the base block 01; the slope of the wedge block 05 exerts force on the slope of the slider 03, so that the protrusion of the slider 03 moves along the rectangular parallelepiped in the elongated slot of the base block 01. The height direction is lifted and lowered, and finally the positioning seat 02 connected with the slider 03 is lifted along the height of the 20H7 long slot on the basic block 01, that is, the height direction of the basic block 01 cuboid, and the lifting range is 0 ~ 10mm. This range value is determined according to the height of the working table of the high-frequency induction welding machine from the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com