Circular blank continuous casting terminal electromagnetic stirring control system

A technology of terminal electromagnetic stirring and control system, which is applied in the field of electromagnetic stirring of large-section round billet continuous casting in steelmaking, can solve the problems of peak current influence and short effective time of terminal electromagnetic stirring, so as to improve the equiaxed crystal rate and solve the effective time. Short and peak current effects, high control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to deepen the understanding and recognition of the present invention, the present invention will be further described and introduced below in conjunction with the accompanying drawings.

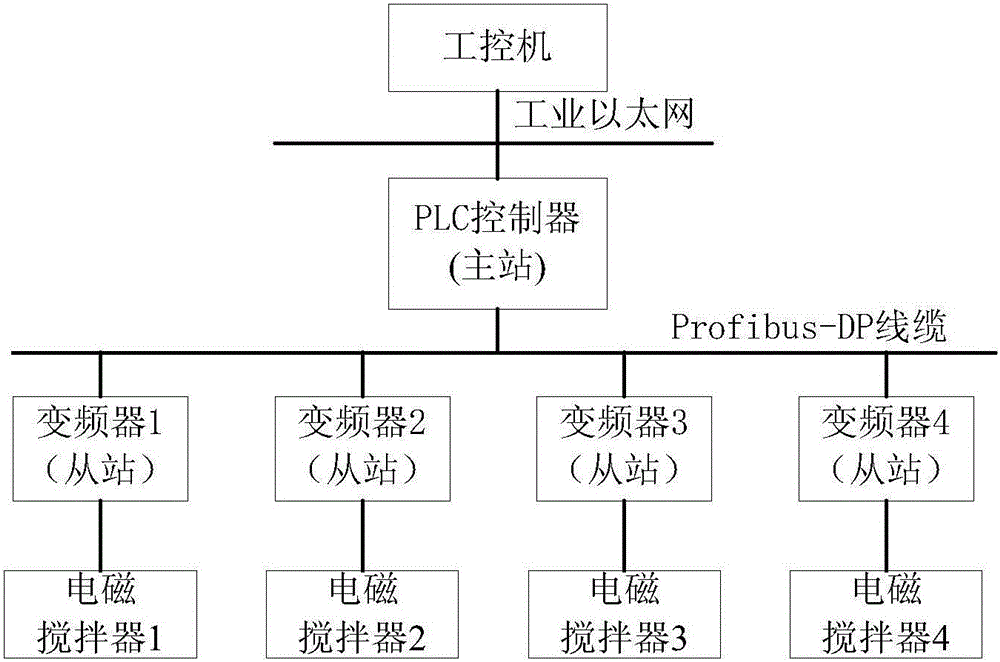

[0023] Such as figure 1 As shown, a round billet continuous casting terminal electromagnetic stirring control system includes an industrial computer, a PLC controller as a master station, four frequency converters as a slave station, and four end electromagnetic stirrers. The industrial computer communicates with the The PLC controller is connected, the industrial computer and the PLC controller communicate through the network, the PLC controller and the frequency converter perform data interaction through the field bus, and the frequency converter and the electromagnetic stirrer are connected through a control cable , The four frequency converters are called "four casting streams", and the four casting streams are controlled by the same PLC controller. All frequency converte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com