Printing conveying device for encrypted light disk production line

A conveying device and production line technology, applied in the direction of pollution prevention methods, cleaning methods using tools, chemical instruments and methods, etc., to achieve the effects of labor saving, convenient operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

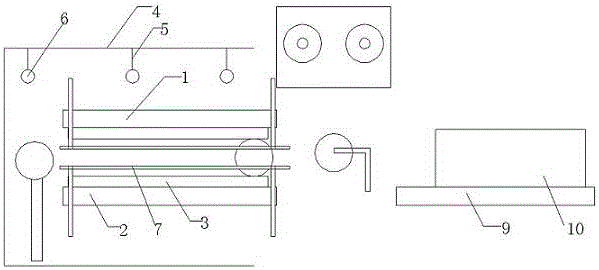

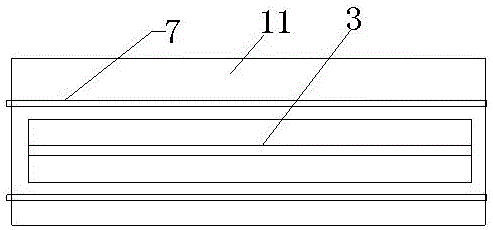

[0014] Such as figure 1 As shown, the present invention is a printing and conveying device for an encrypted optical disk production line. The detected optical disk is placed on the qualified conveyor belt group and the unqualified conveyor belt 9 by the mechanical arm and the vacuum suction cup, and the mechanical arm and the vacuum suction cup of the conveying device pass through PLC control, the PLC controls the mechanical arm and the vacuum suction cup to place the qualified discs on the qualified conveyor belt group after testing, and then place the unqualified discs on the unqualified conveyor belt 9 for recycling, and the unqualified conveyor belt 9 There are b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com